Filters Play Important Part in Compressed Air System Efficiency

The filtration technology utilized in a compressed air system can play an important role in reducing energy consumption as Donaldson Co. found after conducting 12 compressed air efficiency projects at its facilities.

By evaluating filtration requirements, and utilizing its own solutions, Donaldson was able to reduce its annual energy demand by 496 MWh which it says is equivalent to the power needed for about 220 electric cars. Compressed air systems are used in a wide range of industrial applications to operate pneumatic components or other tools but are known to be high energy consumers.

Data from the U.S. Department of Energy (DOE) shows about 10% of the electricity consumed by a typical industrial facility is for generating compressed air and could account for 30% or more of the electricity consumed by an operation. The DOE also notes the efficiency of a typical compressed air system can be as low as 10-15%, contributing to higher energy use.

Therefore, finding ways to improve the efficiency of these systems and reduce their energy consumption can have a huge impact on operational costs as well as emissions reduction efforts which are increasing in importance for many companies.

“Better energy management is one of our priority sustainability goals as we target an absolute reduction of greenhouse gas emissions (GHG) by 42% by the end of FY30 from a FY21 baseline,” says Bart Robbeets, General Manager Industrial Gas Filtration, Donaldson. “Filtration technology plays an important role in this.”

Taking a systems-wide approach which includes weighing component options and integration strategies is generally recommended for reducing energy consumption. As Donaldson demonstrated during its own research, filtration selection and integration can play a key role in achieving efficiency goals.

Three Filter Technologies for Optimized Performance and Energy Use

According to Donaldson, using high-quality filters and other components can have a direct impact on reducing energy consumption. Selection of the appropriate filter media and flow-optimized housings helps achieve this while ensuring ISO 8573-1:2010 specifications for compressed air quality are met.

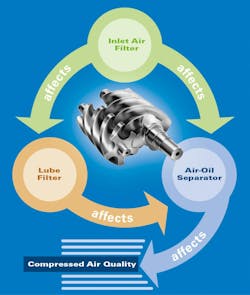

The company says there are three types of filters which make up the filtration system on air compressors – inlet air filters, oil filters and air-oil separators. Their job is to remove particulates and separate oil mist from the airstream without restricting how air moves through the system.

Depending on the chosen solution for each, it may be possible to assure filtration and system performance while improving efficiency.

1. Inlet Air Filters

An inlet air filter is typically included on air compressors as a means of preventing dust and dirt from entering the system. The media for these filters are often made from cellulose fibers or cellulose-synthetic blends.

Donaldson, however, has developed a fine fiber media called Ultra-Web for its inlet air filters. The media features very small inter-fiber spaces to trap dust without negatively impacting airflow through the compressor. It is capable of achieving efficiencies of 99.99%, compared to other media types which typically have efficiencies around 99%.

Ultra-Web captures particles on the surface of the media instead of in the depths of it as some filter types do, helping to extend the life of the filter as well as other filters within the system because particles are prevented from entering it. This also leads to efficiency gains; keeping particles out of the system means it does not have to work as hard to move air and thus uses less energy.

2. Oil Filters

Oil filters, also referred to as lube filters, are also a key component of the filtration process for compressed air systems. These filters keep particulates out of the oil used in compressors for lubrication of components.

While there are some oil-free air compressors, even they require a filter because air itself has small contaminants in it which turn to oil when compressed which need to be removed.

READ MORE: The Differences Between Oil-Free and Oil-Lubricated Air Compressors

For its oil filters, Donaldson has developed Synteq XP, a resin-free filtration media with lower flow restrictions than standard cellulose media. According to the company, it is a more uniform media with more pore openings than cellulose versions which improves its ability to capture particles as well as its efficiency.

Synteq XP is also designed to last longer, helping to extend the life of the filter for lower maintenance and operational costs.

3. Air-Oil Separator

The final filter through which air travels before it leaves a compressor is the air-oil separator. This device ensures any oil that may still be in the air is removed.

As with the other air compressor filters, the type of media utilized plays an important role in ensuring performance as well as safety. If the air which leaves a compressor has oil in it, operational and maintenance issues can occur. In addition, for sensitive working environments such as food and beverage production any potential contamination caused by oil being in the compressed air could lead to health concerns.

ISO 8573-1:2010 specifies the allowable levels of oil and other contaminants that can be in compressed air streams. The recommended amount of oil present in compressed air, known as oil carryover, is about 3 ppm (parts per million); anything over that is when issues may occur.

Donaldson’s air-oil separators come standard with its Synteq filtration media and premium versions with Synteq XP, which again enables a high level of particle containment without impeding airflow through the system – and thus ensuring the system’s efficiency and performance. With its ability to trap and retain a large amount of particulate, the media also ensures low oil carryover.

More Filtration and Energy Savings Potential

Additional treatment of compressed air occurs once it leaves the compressor, further assuring its quality when it reaches the point of use. Here again the chosen technology can impact filtration quality as well as operational efficiency.

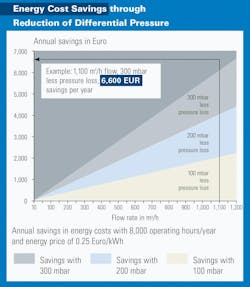

To help meet performance and efficiency goals, Donaldson developed its UltraPleat technology for compressed air treatment. It is a pleated filter media comprised of coated high-tech fibers which the company says provides a surface area over 400% larger than traditional media – enabling a high level of separation efficiency for liquid and solid particles. Per Donaldson, the filter attains an oil aerosol separation efficiency of ≥99.9% according to ISO standards while concurrently cutting the differential pressure by 50%.

In Figure 3 below, Donaldson illustrates the economic benefits possible when using the UltraPleat filtration solution using the following example: a 300-mbar reduction in differential pressure over 8,000 operating hours translates to approximately £5,650 in savings per UltraPleat filter annually (considering 7 bar system pressure, 110 kW installed compressor power, and a cost of 0.21 p/kWh).

Further efficiency gains can be achieved when the UltraPleat technology is paired with flow-optimized filter housings according to the company. In addition, integration of a monitoring system can improve operational costs by enabling better insight into potential maintenance needs before costly downtime issues occur.

Through its continued technology developments, Donaldson aims to provide users the filtration solutions they need to ensure both performance and efficiency. And by deploying these technologies at its own facilities, the company demonstrates what is possible for others utilizing compressed air systems.

READ MORE: Is high-quality filtration a luxury or a necessity?

About the Author

Sara Jensen

Executive Editor, Power & Motion

Sara Jensen is executive editor of Power & Motion, directing expanded coverage into the modern fluid power space, as well as mechatronic and smart technologies. She has over 15 years of publishing experience. Prior to Power & Motion she spent 11 years with a trade publication for engineers of heavy-duty equipment, the last 3 of which were as the editor and brand lead. Over the course of her time in the B2B industry, Sara has gained an extensive knowledge of various heavy-duty equipment industries — including construction, agriculture, mining and on-road trucks —along with the systems and market trends which impact them such as fluid power and electronic motion control technologies.

You can follow Sara and Power & Motion via the following social media handles:

X (formerly Twitter): @TechnlgyEditor and @PowerMotionTech

LinkedIn: @SaraJensen and @Power&Motion

Facebook: @PowerMotionTech