A Positive Outlook for Pneumatics Market in 2025

The pneumatics industry, like many others, faced complex market conditions in 2024 due to a range of factors including labor shortages, high interest rates and ongoing supply chain challenges.

Uncertainty about the global economy and outcome of the U.S. presidential election (which had not yet taken place at the time this interview was conducted) have added to the market's complexity by causing many organizations to delay projects said Andy Thedjoprasetyono, Manager, New Product Marketing at SMC. Corp.

However, these challenges have not impeded innovation or the technological opportunities SMC sees for the pneumatics sector. Automation, sustainability and system monitoring are just some of the areas in which the company, and the pneumatics industry as a whole, are focusing current and future development efforts.

In this Q&A with Power & Motion, Thedjoprasetyono and two other subject matter experts from SMC Corp. offer their insight into market conditions for the pneumatics industry as well as the technological development opportunities which lie ahead.

*Editor's Note: Questions and responses have been edited for clarity.

Power & Motion: How has 2024 been for SMC and the pneumatics industry as a whole?

Andy Thedjoprasetyono, Manager, New Product Marketing: 2024 has presented a complex landscape for SMC and the industry at large. While certain sectors have experienced growth, persistent challenges such as inflation, supply chain disruptions, labor shortages, and geopolitical risks continue to impact the industry. In an effort to mitigate fears of component shortages, companies still grappling with the repercussions of the pandemic and persistent supply chain disruptions have inflated their inventories, which has dampened demand this year. Furthermore, the election year has led many organizations to postpone projects and significant capital expenditures, adding another layer of complexity to decision-making and investment strategies.

Despite these challenges, SMC remains committed to strategic investments. We have made substantial capital investments worldwide to bolster our supply chain capabilities and implement Business Continuity Planning (BCP), including diversifying procurement sources. Additionally, we are focused on developing new products that address the growing demand for lower-pressure solutions, thereby contributing to significant CO2 (carbon dioxide) reductions for our customers.

Power & Motion: What have been some of the biggest challenges, and opportunities, in 2024?

Andy Thedjoprasetyono: Challenges have included —

- Inflationary pressures: Rising costs of raw materials, energy, and labor have strained budgets.

- Skilled labor shortage: A lack of skilled workers has impacted production efficiency and overall operations.

- Economic uncertainty: Global factors, including recession fears and geopolitical tensions, have created an unpredictable business environment.

- Market hesitancy: Many machine builders and end-users are reluctant to commit to large-scale projects, delaying implementation until 2025 despite available engineering resources.

Opportunities seen in 2024—

- Focus on total cost of ownership: The push to reduce total cost of ownership (TCO) aligns with SMC’s mission to develop energy-efficient products, helping customers decrease air and CO2 consumption and cost.

- Automation: The need to address a declining labor force presents opportunities to implement automation in monotonous or hazardous tasks, such as palletizing and welding. This shift can enhance productivity and create new roles for technicians and engineers.

- Demand for data and monitoring: There is a growing need for sensors and monitoring devices, as customers seek advanced data analytics to improve machine performance, making data-driven decisions to save on cost and energy usage.

- Sustainability commitment: SMC is dedicated to environmental stewardship, continuously re-engineering products to maximize value while minimizing ecological impact, thus positioning ourselves as a leader in innovative, eco-friendly solutions.

Power & Motion: What features or capabilities are customers currently looking for from pneumatic components and systems? What industry trends are currently having the largest impact on your pneumatic designs, and could you offer examples of specific ways in which they are being impacted?

Nathan Eisel, National Product Development Manager, Digital Architecture: Customers today are increasingly seeking advanced features in pneumatic components and systems to enhance performance, efficiency, and sustainability, particularly in light of trends toward smart factories, Industry 4.0, and the Industrial Internet of Things (IIoT). To meet these demands, pneumatic components must integrate smart technologies, including sensors, connectivity, and IO-Link capabilities for digital control and real-time monitoring.

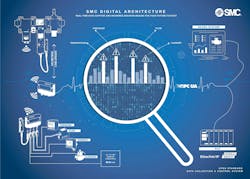

SMC's AMS Series Air Management System exemplifies these innovations by monitoring and optimizing compressed air use, automatically reducing pressure to idle machines, and cutting air supply during shutdowns. It also transmits valuable machine data, offering insights that enhance decision-making and operational efficiency. The AMS is a key component of SMC’s Digital Architecture, which integrates open-standard technologies with cutting-edge innovations to enable comprehensive data collection and informed decision-making across industrial automation.

Another notable product, the VBA Series Energy Saving Booster Regulator, allows users to increase pressure only where needed. This localized approach reduces overall factory line pressure and optimizes energy consumption by eliminating unnecessary high-pressure air throughout the system.

Customers are also increasingly looking for products with extended lifecycles to minimize maintenance and replacement costs. In response, SMC has developed the High Durability series of pneumatic actuators, which last four times longer than standard options.

The trend toward compact and lightweight designs is essential to save space and materials. Lightweight products also reduce the payload on end-of-arm tooling (EOAT), leading to further energy savings. SMC’s J-Series pneumatic actuators are specifically engineered to be compact and lightweight, enhancing overall system efficiency while meeting these industry demands.

Furthermore, SMC’s EXW1 Series Wireless Communication Module effectively addresses the dual demands for smart technologies and compact design. Its wireless functionality eliminates wiring clutter, optimizing space without compromising performance. This module seamlessly communicates essential feedback to SMC’s Digital Architecture system, meeting the growing demand for integrated solutions in a space-efficient manner. As a testament to SMC's commitment to innovation, the EXW1 exemplifies our dedication to creating smart, durable, and space-saving designs.

Power & Motion: Are there any new trends or technology needs you see entering the pneumatics market and influencing future designs? If so, what are these and what impacts do you see them having?

Jesse DeSanto, National Product Development Manager, End Effectors & Low Vacuum: In addition to the increasing demand for smart technologies — such as sensors, connectivity, and digital monitoring — that enable data-driven decision making and energy savings, there is a rising need for automation as a whole to address labor shortages and create safer, more efficient production environments. SMC envisions a future where automation expands into markets that have not traditionally relied on it, driving significant advancements in industries such as fast food, agriculture, and construction. Each of these sectors presents unique design challenges that will drive innovation.

In fast food, components need to be washdown-resistant with smooth, seamless surfaces that inhibit bacterial growth. This design is essential not only for cleanliness but also for meeting stringent health and safety regulations. The ability to easily clean equipment can lead to faster turnaround times and improved food safety, ultimately benefiting both customers and operators.

The agricultural industry requires machinery and components to be robust and weather resistant. Automation in agriculture can enhance productivity through precision farming techniques, which rely on technology to optimize crop yields and reduce waste.

The construction industry faces challenges akin to those in agriculture, requiring equipment to be exceptionally durable, weatherproof, UV resistant, and dust resistant to withstand harsh conditions and ensure longevity on job sites. This durability is crucial for maintaining productivity and safety in environments where machinery is often exposed to the elements.

By addressing these challenges, automation will not only improve safety but also reduce labor costs and enhance the quality of work and products produced. As these industries evolve, the integration of advanced automation technologies will lead to more efficient and sustainable operations, paving the way for a new era of productivity and innovation.

Power & Motion: What opportunity areas do you see for pneumatics in the coming 1-2 years?

Nathan Eisel: The marketplace is evolving at an unprecedented pace, creating dynamic shifts that present new opportunities for pneumatics in the coming 1-2 years. As the realms of Operational Technologies and Information Technologies converge, there will be an increased demand for instrumentation and electronics. This trend, combined with tighter controls on consumables and the need to maximize Overall Equipment Effectiveness (OEE), necessitates heightened efficiency in production processes. SMC is well-positioned to meet these demands with our feature-rich system, SMC Digital Architecture.

Jesse DeSanto: We anticipate significant growth in applications such as palletizing, machine tending, and welding, all of which will create opportunities for industrial and collaborative robot solutions. Additionally, there is exciting potential in shipping and port automation. By leveraging advanced technologies like robotics and AI (artificial intelligence), ports can optimize logistics, improve turnaround times, and enhance overall supply chain efficiency, leading to substantial cost savings and increased competitiveness in global markets.

Overall, the next few years promise to be transformative for automation across these critical sectors, driving improvements in productivity, safety, and operational efficiency. As we embrace these advancements, we can look forward to reshaping the future of work and enhancing the quality of products and services across the board.

Power & Motion: Many market reports indicate 2025 will be the start of better market conditions for many sectors — so how are you and SMC feeling about 2025? And what factors are influencing your perspectives on the coming year?

Andy Thedjoprasetyono: We're optimistic about the potential of 2025, with several factors influencing our positive outlook. The forecast for a rebound in key sectors, particularly the semiconductor and automotive industries, aligns with our expectations as these areas are significant drivers of demand for our pneumatic solutions.

The conclusion of the upcoming elections is also expected to bring much-needed clarity to the market, allowing companies to make decisions and advance initiatives that have previously been hindered by uncertainty. This renewed confidence is likely to encourage businesses to invest in new projects and capital expenditures, driving growth across various sectors.

As bloated inventories begin to be consumed, we anticipate a surge in new orders as customers seek to replenish stock, creating a ripple effect throughout the supply chain and prompting manufacturers to ramp up production. Furthermore, as businesses refocus on growth and innovation, we expect a resurgence in collaboration and investment in new technologies, paving the way for enhanced efficiency and competitiveness.

Overall, these dynamics position 2025 as a year of recovery and opportunity for many industries, and SMC is well prepared to capitalize on these trends while continuing to prioritize innovation and customer needs.