How Fluid Power can Benefit from AI and Machine Learning

Artificial intelligence (AI) and machine learning (ML) have become big topics in many industries and the news. But for those in the hydraulics and pneumatics sector, use of these technologies currently remains limited.

In Power & Motion’s 2024 Salary & Career Survey, respondents were asked about technologies having a major impact on their designs and just 16% indicated AI and ML were making an impact.

When asked how AI and ML have affected their jobs, 41% of respondents said they don’t use these technologies anywhere. Another 23% said they are still evaluating it for their business and almost 18% said they are still evaluating AI and ML for use in their products. About 40% said it is in the office, design and collaboration tools they use.

Many respondents, 31%, do not believe AI and ML are ready for use in the hydraulics and pneumatics sector. This is in line with information presented by Mike Marks, Indian River Consulting Group during the National Fluid Power Association’s (NFPA) 2024 Industry & Economic Outlook Conference (IEOC).

Marks worked with NFPA to find out how the fluid power industry is using AI, if at all, and said 48% said they are just watching what happens while 31% are actively engaged in learning how to utilize it. The crux of his presentation was that right now there is a lot of hype around AI, and it is evolving quickly. While use cases exist, the industry should take its time to see how it will evolve and research how best it can be applied to hydraulics and pneumatics.

Defining Artificial Intelligence and Machine Learning

Though the terms artificial intelligence and machine learning are used more frequently today, understanding what they mean, and how they differ from one another, may still be unclear.

Artificial intelligence, or more commonly these days AI, is defined as computer systems performing tasks typically completed by a human. Visual perception, decision-making, and language translations are a few examples.

Machine learning (ML) is considered a branch of artificial intelligence in which computers and machines use algorithms and statistical models to learn and adapt without being given instructions.

Microsoft describes the difference between AI and ML as thus: “An ‘intelligent’ computer uses AI to think like a human and perform tasks on its own. Machine learning is how a computer system develops its intelligence.”

He said AI is not something to be afraid of, but fluid power manufacturers should be wary of spending money on it until they’ve spent time learning how to use it and working with it to find the applications which best fit their needs.

Power & Motion decided to dig into this topic further to hear from additional members of the fluid power industry to learn how they might be using AI and ML, and what benefits can potentially be achieved with these technologies.

Fluid Power Can Benefit from Using Artificial Intelligence and Machine Learning

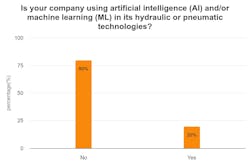

Use of AI and ML in fluid power systems appears to be minimal at the moment as indicated by the results of an additional brief reader survey conducted by Power & Motion. When asked if their company is currently using artificial intelligence and/or machine learning in hydraulic or pneumatic technologies, 80% said no and 20% responded they are using these technologies.

Emerson is an example of such a company utilizing AI and ML in its fluid power systems. Amit Patel, Director Intelligent Automation at Emerson Discrete Automation, said in an interview with Power & Motion that the company is increasingly incorporating AI and ML into its pneumatic solutions.

“While condition-based monitoring can be effective for straightforward machine data and KPIs, it often falls short when trying to build more complex relationships between data to drive predictability and continuous improvement,” he explained. “Our goal at Emerson is to leverage AI and ML to help our customers and their industries improve the quality of data-driven decisions. As a result, they can accelerate and take larger steps across key use-cases such as optimizing machine performance, driving sustainable growth and unlocking workforce potential.”

To achieve these goals, Patel said the first step is defining a clear use case problem followed by identifying and collecting the data. Integration of sensors into valves, actuators or within the pneumatic circuit enables collection of real-time data on various parameters including pressure, flow and temperature.

“After training the models to be robust, we can leverage Emerson analytics platforms to deploy AI and ML algorithms to detect anomalies and pinpoint and alert operators to potential issues before they cause unplanned downtime,” he said. “These insights can inform more energy-efficient operations by continuously learning and adjusting system parameters, ensuring that our customers benefit from consistent, reliable performance in their critical pneumatic applications.”

Patel said Emerson sees numerous opportunities for use of AI and ML in fluid power systems, both now and in the future. “Energy efficiency and predictive maintenance are two of the most immediate use cases — AI-enabled systems can continuously monitor component performance and environmental conditions, learning typical operating baselines so they can quickly detect anomalies or inefficiencies,” he explained. “Over time, this leads to reduced unit costs, improved quality and minimized downtime.”

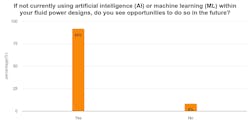

Survey respondents agreed that there are opportunities to use AI and ML in fluid power designs in the future, with 92% indicating as such.

Like Emerson, many survey respondents indicated predictive maintenance as an opportunity area for AI and ML. Others see these technologies enabling the creation of autonomous machines in both mobile and industrial applications.

Several respondents also pointed to use of AI and ML in various design tools as a future benefit they envision. Many noted improved design optimization, modeling, calculation and selection of components, as well as the ability to speed up the design process when using these technologies.

Reducing the mass of components and delivering more precise control were additional design benefits cited by one respondent.

Challenges Remain but AI has a Future in Hydraulics and Pneumatics

Although there are many opportunities in utilizing AI and ML, there are still several challenges to overcome when employing these technologies in fluid power systems – as evidenced by our survey results showing the lower percentage of companies utilizing the technologies currently.

Talent shortages are chief among these. “We’re seeing a shortage of domain expertise and skills,” said Patel. “Finding the right talent of workers with the necessary skills to effectively implement and utilize AI and ML technologies can prove challenging.”

On the technological side of things, other challenges he noted include:

- safety, reliability and scalability

- ensuring sufficient data quality, volume and availability from sensors

- integrating OT (operational technology) and IT (information technology) infrastructures.

“Over 90% of companies still struggle with successfully deploying and/or scaling the value of AI and ML in industrial settings,” he said. In addition, rigorous validation is required in mission-critical applications to assure safe and reliable operation. “Organizations must also address skill gaps and develop scalable solutions that can handle growing data volumes.

“Balancing the cost of AI investments with clear return on investment requires careful planning, execution and governance to ensure long-term benefits and viability,” said Patel.

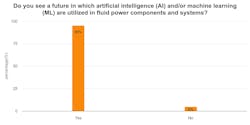

Despite the challenges associated with using AI and ML in fluid power systems, it appears the industry is optimistic about the future opportunities these technologies could provide. The majority of survey respondents, 95%, said they see a future in which artificial intelligence and/or machine learning are utilized in fluid power systems.

Emerson also foresees a future in which these technologies will be utilized in hydraulic and pneumatic systems. Patel said that computing power continues to improve the ability to directly integrate AI and ML on a device.

“Self-regulating systems also enable dynamic optimization of system parameters such as pressure, flow rate and actuation speed based on actual operating conditions rather than static setpoints,” he said. “This adaptability helps improve energy efficiency while reducing wear on components.

“In the long run, we expect fluid power systems to evolve into fully intelligent networks and platforms like digital twins, where AI-driven insights coordinate and self-correct processes,” he concluded.

About the Author

Sara Jensen

Executive Editor, Power & Motion

Sara Jensen is executive editor of Power & Motion, directing expanded coverage into the modern fluid power space, as well as mechatronic and smart technologies. She has over 15 years of publishing experience. Prior to Power & Motion she spent 11 years with a trade publication for engineers of heavy-duty equipment, the last 3 of which were as the editor and brand lead. Over the course of her time in the B2B industry, Sara has gained an extensive knowledge of various heavy-duty equipment industries — including construction, agriculture, mining and on-road trucks —along with the systems and market trends which impact them such as fluid power and electronic motion control technologies.

You can follow Sara and Power & Motion via the following social media handles:

X (formerly Twitter): @TechnlgyEditor and @PowerMotionTech

LinkedIn: @SaraJensen and @Power&Motion

Facebook: @PowerMotionTech