By Claire S. Goodwin, Scott Rotary Seals, Inc., Hinsdale, N.Y.

Using pneumatic cylinder-powered clamps to hold parts in place is a widespread practice, found in many automation sequences. When these sequences take place on a rotary index table, supplying and controlling compressed-air flow to a series of cylinders may become complex. (Manual clamping and unclamping is always an option - but they eliminate the desired automation of operation.) Add other pneumatic devices, and space limitations may prohibit the installation of conventional valving.

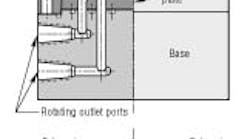

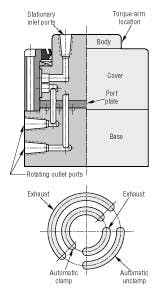

A rotating union and manifold can bring air to the rotary table but they only provide continuous flow. It still is necessary to control flow to the individual devices that are incorporated into the application.

Consider a simple, 6-position index table on which small parts are loaded into clamp fixtures. The clamps then close to hold the parts during subsequent operations that take place at the other index positions. Finally, of course, the part must be unclamped for removal at the unload position. If the clamp cylinders are single acting, six clamps would require six air connections through a 6-port rotating union to bring individual supply lines to each table station. Each port, in turn, still would need a method to turn on the air for clamping and exhaust it to unclamp. This adds six directional valves to accomplish the clamping sequence. Double-acting cylinders double the circuit complexity, calling for a dozen port connections, two at each station.