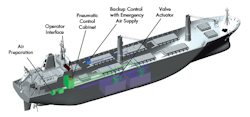

The Marex Valve Control System uses pneumatic valve actuators to control ballast, even if a power outage occurs.

Depending on the size of the ship, a Marex VCS can work up to 100 ballast and quick-release valves, including air preparation and all necessary operating and control modules. The standard working pressure is 5 to 7 bar, and if a power failure occurs, the crew can generate working pressure using one or more manual pumps.

In the Control Room

Marex AMC operating and control modules can control the ballast-valve control system. This automation system, used extensively in shipping, allows structured access to all ballast-valve control-system information and functions. Furthermore, it groups and displays additional systems, such as the engine, reversing gear, and other functions.

The modular system communicates with the ballast-valve control system via CAN bus. It features a self-explanatory touchscreen controller that mimics the ship’s movements and simplifies operation—a major demand within the shipping industry.

If the main system fails, the valves can be controlled via a backup control and backup system, which are located outside the engine control room. This includes one or more manual pumps that ensure the ability to function in the event of a power outage.

These purely pneumatic actuators function in a wide range of environments: ballast, bilge, and heavy fuel-oil tanks. The Marex systems meet ATEX specifications for all ships and installations with explosive protection requirements.

Hunsche adds that the Marex VCS is certified for use in ships and offshore installations by the world’s leading classification societies. “The system is based on large-scale series components that are available across the globe.”

For more information on Marex and other Aventics products and services, visit www.aventics.us or call (859) 259-3817.

Looking for products? Go to SourceESB.