MEMS Proportional Control Valves Enable Lightweight Orthoses

Ten research projects out of the Center for Compact and Efficient Fluid Power (CCEFP) were chosen for funding by the NFPA last fall and presented at the Fluid Power Innovation and Research Conference (FPIRC). The projects pertain to five sectors in fluid-power research: human-scale technologies, mobile applications, manufacturing, stationary equipment, and fluids/tribology.

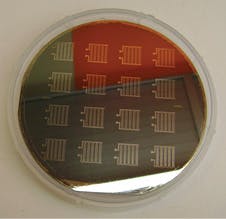

The first project—a Hybrid MEMS Proportional Fluid Control Valve—is for motion control in orthoses, wearables, and other human-scale technologies. Like most MEMS, which is an acronym for micro-electro mechanical systems, it contains tiny components on a lightweight chip that perform mechanical tasks as part of a larger system.

Designed by a multi-institutional team led by the University of Minnesota, the hybrid MEMS uses an orifice-array baseplate that interfaces with microscopic piezoelectric actuators on another plate. The actuators are arranged in parallel to improve the uniformity of the pressure drop through each orifice. The MEMS works at pressures that are sufficient to supply airflow to larger pneumatic actuators. It was designed for an ankle orthosis from the University of Illinois at Champaign-Urbana.

The actuators respond to a small voltage generated by two electrodes over the actuator plate. Depending on the strength of the electrical signal, the piezoelectric material will bend to proportionally open and close the orifices. By using a more reactive piezoelectric material over the bending axis and a less responsive one below, the team could achieve higher bending strength compared to actuators that use only one material (bimorph vs. unimorph).

The MEMS technology could replace bulkier solenoid valves in orthoses, which are used to assist patients' movements while they heal from injuries. Until then, the team needs to investigate more clean-room techniques and materials that can be used for more reliable construction.

Overall, the research meets the CCEFP's mission to produce streamlined fluid power actuators and systems. Because the piezoelectric actuators are low energy, they could be powered throughout the day using only a small battery, improving the overall comfort and weight of orthoses.

Testing

Initial testing was done on an ISO test bench using a meso-scale orifice and actuator plates, which was twenty times larger than the MEMS. The team then tested their concept using MEMS with different orifice diameters. They found that an orifice diameter of 80 microns could withstand their target pressure of 100 psi without requiring very high actuator strength, which can be hard to provide, since the actuators are very thin.