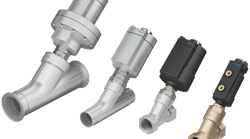

Festo VZXA Angle Seat Valves Designed for Ease of Use

Festo’s VZXA line of pneumatically actuated angle seat valves feature a modular design which ease their installation and maintenance. The valves enable high volume flow control of water, steam and corrosive materials.

Key features of the VZXA angle seat valves include:

- wide temperature and pressure range capabilities

- stem, seat, and seal stay inside valve body during maintenance, maintaining system pressurization

- reinstallation requires only valve body to be screwed into place

- modular design suits use in valve manifold applications

READ MORE - Fundamentals of Fluid Power: Pneumatics

Modular Valve Design Benefits Ease of Use

Festo developed its VZXA angle seat valves with simplicity in mind. Installation, maintenance and even ordering is easy for customers. The valve family features a standardized design so each VZXA actuator is compatible with every valve body in the lineup while the stem, seat and seal are treated as individual components which are modular and can easily be replaced.

According to Festo, the VZXA's modular design is particularly beneficial for manifold applications in which fast assembly and ease of maintenance are desired. The compact footprint of the angle seat valves is a desirable feature for manifolds as well.

The actuators and valve bodies have a universal fit with one another, further simplifying repairs and ordering. Festo has created an online valve configurator to help customers find the right valve for their application. Standard or custom valves are available as well as normally open, normally closed and double acting actuators.

READ MORE - Festo Pneumatic Essentials Program Streamlines Order and Delivery Process

When maintenance or changeover is required for the VZXA actuator, the process system is able to stay pressurized because the stem, seat and seal remain in the valve body. This can be particularly beneficial for applications containing hazardous materials as they stay with the system, maintaining safety while reducing cleaning time and potential health risks.

Reinstallation of the actuator simply requires screwing it into the valve body. There is no need to pressurize it, which Festo states in its press release announcing the launch of the VZXA eliminates strain on the stem, seat and seal. This also helps to prevent potential damage to the valve seat.

Options to Meet Varied Applications

As angle seat valves are utilized in a variety of applications with wide temperature and pressure ranges, Festo offers several options with the VZXA family to accommodate these.

Threaded, sanitary clamp and welded end line connections are available. The company notes in its press release that sanitary clamps are best suited for washdown and clean-in-place applications which benefit from quick connect/disconnect capabilities.

The valve body materials include stainless steel and brass while actuator bodies can be made from stainless steel or polymer. An optical indicator is included on each actuator to show the valve position, further benefitting ease of installation.

Several accessories are available for the VZXA valves including sensors offering digital feedback, a piloting banjo valve and stroke limiter.

Valve bodies are available in sizes up to 2 in.