Additive Manufacturing Brings Opportunities to Improve Component Design and Production

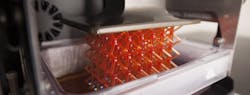

Additive manufacturing—also commonly referred to as 3D printing—continues to make headway in many industries, including fluid power.

Valeria Tirelli, president & CEO of Aidro Hydraulics & 3D Printing (a Desktop Metal company) and member of Power & Motion’s Editorial Advisory Board, said her company discovered additive manufacturing a few years ago. “At the beginning the idea was to use additive manufacturing for making tooling or prototypes for our hydraulics production.” But as the company worked with it more and understood the potential of the technology, Aidro realized it could change how it went about designing its parts and adopt the principles of additive manufacturing which is to add material only where it is needed.

As Tirelli explained, additive manufacturing offers a completely different approach from conventional manufacturing of hydraulics parts. Instead of starting with a metal block which is machined, metal powder is layered and added where necessary. This leads to the ability to create new, more optimized designs with varying geometries and even the ability to reduce part counts and component weight.

READ MORE: Lightweight Hydraulics Offer New Opportunities to Manufacturers

Improved Manufacturing Potential

Tirelli noted there are many advantages additive manufacturing can offer. Among them is the ability to integrate multiple parts into a single unit. Instead of assembling three or four components such as valves and manifolds, a single part can be designed which incorporates those components.

This can help with weight savings and eliminates the need for assembling as well as the potential for leakage from coupling multiple parts. It also reduces the amount of machining required for the different parts.

Improved sustainability is also possible with additive manufacturing she said. Less material and energy are used than with conventional manufacturing methods. Because there is less material used, the amount of machining typically required is again reduced which equates to less energy used to produce parts.

Creation of lighter weight parts through the use of additive manufacturing can benefit sustainability efforts, as well, particularly for the end use customer of the part. Vehicles or mobile machinery into which the lightweight parts are installed can benefit from improved fuel efficiency as use of lighter weight components helps reduce overall vehicle weight and thus fuel use.

And as mobile industries move toward further electrification, the ability to create and utilize lightweight components will be particularly beneficial to compensate for the heavier weight of other components like batteries and ensure desired efficiency gains are achieved.To help improve sustainability on the design side, PolySpectra—a company developing advanced photopolymers for additive manufacturing—has created an augmented reality (AR) tool which can help prove out designs before creating them. This helps to reduce the amount of material that would be used for a prototype that may just then get thrown away.

“There is so much 3D printing that happens just to visualize how a part is going to [look and feel],” explained Raymond Weitekamp, founder of PolySpectra. No matter how good a person is with CAD and evaluating all possible angles and dimensions of a part, it will still wind up being printed then possibly thrown away because the shape was not what originally thought.

PolySpectra’s free, web-based tool allows users to upload their STL files—the standard file type for 3D printing—to get an instant AR preview of their design. Once uploaded, the AR rendering can be moved via the computer’s curser to see how it will look from a variety of angles. A QR code allows files to be viewed on mobile phones for further ease of use. Visit ar.polyspectra.com to preview and use the AR tool.With this tool, design teams can evaluate what Weitekamp referred to as a massless prototype. Although it cannot be tested in the same manner as a physical prototype, it allows evaluation of designs at an earlier stage and the ability to make modifications before printing which reduces material waste and printing time.

While the rendering in the AR tool may not be perfect or look exactly the same as it would in real life, said Weitekamp, it allows fast iterations of designs. “You could change the design and reload the preview every few seconds if you needed to in that phase,” he said which could benefit the development process.

He noted that many times what may seem like a good design in CAD once 3D printed turns out not to be. By using the AR tool, designs can be better proved out without wasting material, time or fully printed parts.

As AR technology continues to advance, so too will the possibilities for quickly evaluating and modifying designs. “What I think is really exciting about this idea of massless manufacturing or prototyping is you can still have [customization and options] with a dramatically lower carbon footprint,” said Weitekamp.

Digital and Supply Chain Opportunities

Digitalization of the manufacturing process is another advantage additive manufacturing can provide. Tools like PolySpectra’s, for instance, can enable digital files to be easily viewed and shared.

“One of the visions of 3D printing is to go towards what I would call distributed digital manufacturing, but one version of that some people call the virtual warehouse,” said Weitekamp. Instead of having a warehouse full of components which need to be kept track of, companies could have a database of files. When parts are needed, the appropriate files are found and 3D printed.This could greatly save on warehousing space as well as time spent tracking the whereabouts of parts. It could also aid supply chains by minimizing the number of parts a company ships as it could 3D print them instead.

Tirelli also noted the benefit of additive manufacturing for spare parts production. “With additive manufacturing, we have the possibility to create a digital inventory. So instead of having a physical part in inventory and keeping it for maybe 20 years, with additive manufacturing we can keep the file [and 3D print] on demand.”

Production on demand can be used to produce parts that might otherwise be out of production as well as offer the opportunity to produce parts where and when they are needed because files can be kept and sent digitally. This can enable local printing of parts, said Tirelli which saves on costs not only for inventory but also shipping and transport.

Vehicle OEM Daimler Buses announced in May 2022 owners of Mercedes-Benz and Setra buses and touring coaches will be able to 3D print spare parts at their own premises. Customers will need a certified 3D printer, a one-off registration process and a license for the required part in the desired quantity the company said in its press release announcing this new offering.

This new offering makes it quicker and easier for customers to get the spare parts they need, helping minimize their downtime which can be costly. Starting in June 2022, more than 100 parts of the currently more than 1,500 different 3D-printable components will be available as the first licenses from the digital warehouse said Daimler Buses in its press release. More parts will be added in the future.

Improving supply chains through these digital capabilities is a key advantage many see for additive manufacturing. By enabling parts to be produced on demand where needed, there will be less reliance on shipping and thus fewer issues with supply chains as many are currently facing.

Tirelli noted the ability to integrate multiple parts into a single unit can also benefit supply chains by reducing how many parts need to be shipped.

In early May 2022, U.S. President Joe Biden launched a 3D printing initiative as a means of improving supply chains. Known as AM Forward, the goal is to have private sector companies purchase parts produced using additive manufacturing (AM) from smaller U.S.-based suppliers reports The Hill.

Initial companies participating in AM Forward include GE Aviation, Honeywell, Lockheed Martin, Raytheon, and Siemens Energy.

Material Options Area of Continued Development

The materials used for additive manufacturing remain an area in which companies are working to make further advancements. Weitekamp said PolySpectra’s development of advanced photopolymers for additive manufacturing aim to overcome the durability issues of polymers typically used.

“Most polymers that can be 3D printed are not rugged enough to be directly incorporated into an industrial end-use component,” he said.

As he explained, there are materials which become brittle when they get hot while others are tough but lose their mechanical integrity once they get warm. PolySpectra was founded to overcome this challenge by using completely new chemistry based on a catalyst which Weitekamp said won a Nobel Prize in 2005.

The result, COR Alpha, is a polymer which is capable of being tough and hot at the same time. This provides various industries with a material rugged enough to survive under higher temperatures and harsh environmental conditions, benefiting use for truck and car parts, medical devices, robots and more.

“Without that ability to meet the same performance or safety criteria of the existing injection molding or CNC methods, you can't even start to do the really fun stuff that additive manufacturing promises,” said Weitekamp.

Despite PolySpectra’s material being a polymer—or essentially a high-performance plastic—he said its properties could enable it to be a metal substitute which could benefit manufacturers’ lightweighting initiatives as plastic is a less dense material.Metal additive manufacturing is an area in which a lot of research and development efforts are taking place, as well said Jeff Grabowski, Manager of Business Development, QuesTek Innovations, LLC, during his presentation on materials performance for fluid power components at the National Fluid Power Association (NFPA) Fluid Power Industrial Consortium’s (FPIC) March 2022 event. QuesTek is a provider of Integrated Computational Materials Engineering (ICME) technologies and is working to address issues the industry currently faces with using metals for additive manufacturing.

While technical progress has been made in regards to metallic additive manufacturing, Grabowski said there are still many technical questions yet to be resolved regarding mechanical and metallurgical issues. Two of the biggest challenges, and areas in which QuesTek is focusing its research efforts, are issues with some materials and processes not being suited to use for additive manufacturing.

“Typically, the research in metal additive is taking legacy [material] compositions that have been around for 50+ years that were intended for large castings with slow cooling rates, or for forgings that are forged and heat treated,” said Grabowski.

Using these legacy compositions can lead to cracking or low strength when 3D printed. Completely different heat treatments are also necessary when 3D printing parts, he said, which is why most of QuesTek’s additive manufacturing projects are looking at ways to optimize the heat treatment process.

Grabowski said time and again QuesTek has demonstrated that no matter the metal type, proper heat treating of additively printed materials is vital to ensuring the desired strength or other properties are achieved.

QuesTek is also designing new alloys tailored for additive manufacturing which can provide desired properties while using fast cooling rates which cannot be achieved when using a slow cool casting process. The company has also developed a variant of the commonly used 17-4 stainless steel that can be 3D printed and offer the strength properties many applications look for without the need to treat the material.

Read more about the growth of additive manufacturing and material options from our colleagues at Machine Design in the article “The Material Changes in Additive Manufacturing.”

Industry Challenges Yet to be Overcome

Return on investment (ROI) is chief among the challenges still associated with metallic additive manufacturing said Grabowski. The cost of powder versus the cost of bar stock and the cost of printing versus the cost of machining are all aspects that need to be considered. Currently, when looking at these factors, metal additive manufacturing is more expensive, he said.

Aidro’s Tirelli agrees that additive manufacturing can be more costly than traditional processes due in part to it still being considered a newer technology. In addition, she noted there are fewer suppliers of metal power—which is what Aidro uses for its additively manufactured parts—compared to conventional metal bar material, leading to its higher cost.

Industry mentality is another critical aspect which needs to evolve, said Tirelli. Hydraulics and the general mechanical industry is quite conservative, so even though innovations are taking place people within the industry need to open their minds to new design approaches like additive manufacturing. “Additive manufacturing requires a completely new mindset compared to the past,” she said and as engineers see the benefits and opportunities with this technology they will open their minds and start utilizing it more.

To help increase industry knowledge about additive manufacturing, she said Aidro’s approach is to share what it has done and discovered as it has used the technology.

Although costs in some regards may be higher when it comes to additive manufacturing, Weitekamp it might not actually be as expensive as thought because not all costs in the production process are taken into consideration. While a photopolymer may be more costly than a polypropylene or ABS plastic, there are other costs associated with the latter such as molding the plastic which can have a high tooling cost. And if the design changes slightly, there could more costs added he explained.

Overcoming psychological barriers will be important, said Weitekamp. People are used to the manufacturing technologies that exist today and have been around for decades, requiring a shift in mindsets and evaluating all potential costs of the production process.Another key challenge Tirelli noted with additive manufacturing is the lack of knowledge about how to use it. When Aidro decided to invest in additive, she said the company trained its personnel on the technology as well as hired people from outside the hydraulics industry but with expertise in additive manufacturing to help expand its internal knowledge base.

Learning how to use the 3D printers as well as how to design and manufacture components using them takes time, and it can be a disruptive process for companies. But companies should prepare themselves for that because there are also many benefits to using the technology.

When choosing to use additive manufacturing, Tirelli said it is important to find the right products and geometries that will provide the most opportunities because it cannot be used to substitute production of all conventional parts. “We need to identify the good parts; these are the parts with a complex geometry, are experiencing supply chain issues or have some specific requirements like being lighter in weight or more compact,” she said. “If we identify the good parts, then additive manufacturing will be a successful technology.”