Integration of sensors within hydraulic and pneumatic systems continues to grow. Doing so brings a range of benefits including enhanced performance and data collection for improved maintenance and machine monitoring.

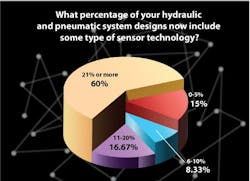

A recent survey of Power & Motion’s audience found a large number of fluid power system designs now include some type of sensor technology. Sixty percent of respondents said 21% or more of their system designs include sensors while another 16% said 11-20% of their systems include sensors.

This coincides with the many discussions we’ve had with members of the fluid power industry who are also witnessing the increased use of sensors in their hydraulic and pneumatic system designs.

There are of course several drivers for the rising use of sensors, with safer and easier operation being chief among them according to Oliver Lythgoe, Chief Marketing Officer at FÉTIS Group, who discussed the topic during a Power & Motion webinar. Adding more electronics, including sensors, to fluid power systems enables these goals to be achieved.

Lythgoe said the integration of sensors allows for new forms of control to enable faster and more accurate movements.

Joern Strasser, Business Manager for Speed Sensors at Rheintacho – who also spoke during the webinar – added that the more a system is controlled, the bigger the advantages which can be achieved. For those in the mobile equipment industry, autonomous driving is one of the next big technological steps manufacturers are looking to take. The measurement and data capabilities provided by sensors will be vital to enabling safe and accurate autonomous driving.

How are Sensors Being Used in Fluid Power Systems

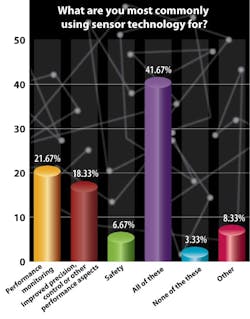

There are a variety of sensors being integrated into fluid power components and systems to meet varied customer needs. Safety, performance monitoring, and improved precision, control or other performance aspects were among the common uses for sensors noted by respondents.

A number of respondents, 41%, indicated all of these were reasons they are including sensors in their hydraulic and pneumatic system designs.

Russ Schneidewind, OEM Sales Manager at HydraForce, said in an interview with Power & Motion that the company is seeing increased demand for precision in proportional control of hydraulic components. Sensors are often being used to provide the feedback necessary to achieve more precise control of hydraulic actuators and motors, he said.

Technological Challenges and Opportunities for Hydraulics and Pneumatics

Although the use of sensors has become more common within the fluid power industry, there are still many challenges faced by the design teams utilizing them. One of the top challenges noted by 21% of survey respondents is the fact that many sensor options remain too expensive. Although their costs have come down in recent years, they can still be a costly part of a system design depending on the type of sensor required and any ruggedness or other aspects which may need to be built into it.

Another 20% of respondents said difficulty integrating sensors into their designs remains a challenge while 6% said not knowing what type of sensor to use can be challenging. Both are important aspects to ensuring a sensor meets the given application and measurement requirements.

There are several sensors available from which to choose – position, temperature, angle and more – making it important for developers of hydraulics and pneumatics to know what they want to accomplish through integration of a sensor.

When it comes to installing a sensor, it is vital to understand the application in which it will be used. In the previously mentioned Rota example, the company had originally thought position sensors embedded in the pile driver’s hydraulic cylinders would be the installation method used. However, Rota found this would not be feasible with one of the hydraulic cylinders because of potential damage to the wire harnesses needed for its sensor. Instead, the company chose an independent mount sensor to keep it protected from damage while still offering the measurement data required by the application.

While there are many sensors available in the market which can be used with fluid power systems, there are also some areas in which the technology is lacking. One of the areas several respondents noted was the lack of multifunctional sensors – i.e., those capable of taking more than one measurement.

Often multiple sensors are integrated into a component or system to gain all of the data that needs to be collected. However, this can be costly and take up valuable installation space. If it were possible to use a single sensor capable of multiple measurements instead, this could help to reduce costs and space requirements for system developers.

There are sensor manufacturers working on this type of technology because they understand the benefits it can provide to the industry. In 2023, Gefran Inc. introduced its Twiist linear position transducer which is capable of providing multiple measurements in a single sensor unit. It features a specialized design to enable linear, angular, and other movements to be measured.

Cost and ease of integration were other areas several survey respondents noted there could be technological improvements made. Additional areas in which it was said sensor technology is lacking include oil film thickness measurements, durability and robustness, continuous fluid level measurements and the need for pressure measurements without wiring and drifting.

In the National Fluid Power Association’s (NFPA) 2023 Technology Roadmap, sensors were noted as a key research area for hydraulic and pneumatic systems. It was noted in the roadmap – a document aimed at guiding future design needs – advancements in materials, wireless sensors, position detection, availability, and real-time information are ways in which sensors could help meet the needs of the fluid power industry.

With these advancements in sensor technology, fluid power systems would be better able to meet the data, safety, and energy efficiency improvements the roadmap committee viewed as vital to ensuring the longevity of the industry.

Sensor Benefits will Lead to Further Growth

Survey respondents unanimously agreed that the integration of sensors in fluid power systems has been beneficial for the industry. When it came to what the biggest benefits have been, however, there was a little more variety in responses.

Many respondents noted the improvements to machine and system monitoring as well as enhanced maintenance capabilities as some of the biggest benefits offered. Improved control and precision were also benefits mentioned by several respondents.

Rex Bateman, Director of Engineering at SMC Corp., told Power & Motion that the ability to integrate industrial networking into control products such as pressure and flow sensors is one of the evolutions taking place in the pneumatics sector which is aiding ease of maintenance. This capability makes it easier to remotely monitor systems and track performance to reduce unplanned downtime.

In general, there are a range of benefits which can be achieved through integration of sensors in fluid power systems. As such, their use will continue to grow in the coming years.

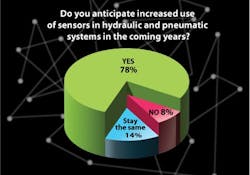

Most respondents, 78%, said they anticipate the use of sensors in hydraulic and pneumatic systems to increase over the next several years. Just 14% expect their use to remain the same while 8% do not anticipate increased use.

Fifty percent of respondents expect sensor use to increase 20% or more over the next 3-5 years, followed by 26% anticipating a 10% increase in use.

As fluid power systems and the applications in which they are used continue to advance, sensors will remain an important part of these system designs and will help bring about numerous enhancements in performance, data collection and other capabilities.