New sensor works as programmable switch

Most air cylinders are used in applications where they repeatedly move from a fully retracted to a fully extended position, then back again. Consequently, most linear position sensors used with pneumatic cylinders consist of switches that sense when the cylinder’s piston or rod has reached the end of its stroke. If the application calls for the switching point to be changed, a technician or mechanic usually must physically reposition the switch. This is one reason why reed switches have become popular with air cylinders — reed switches are compact and easily repositioned. In fact, one common design is so compact that the reed switch fits inside the square channel of ISO cylinders having an extruded aluminum barrel.

Brad Engstrand, president of Motion Controls LLC, Hartford, Wis., came up with a better idea. He knew that a sensor capable of providing continuous feedback of piston position would be a better solution because it would allow changing switching points without having to reposition a reed switch or make other physical adjustments. A sensor with continuous feedback (a linear displacement transducer, or LDT) could be used as a programmable switch, so different — or additional — switching points could be established simply be reprogramming a control.

New technology in sight

LDTs are, of course, used in pneumatic cylinders, but to a limited extent. Their main limitation is the challenge of achieving precise positioning with pneumatics due to the compressibility of air. Plus, non-contact devices add substantial cost to an otherwise economical cylinder. Linear potentiometers are more economical, but the physical contact inherent to their operation limits their life and reliability. Even if the application doesn’t require continuous feedback of position, the limitations of LDTs have kept them from gaining widespread use as programmable switches in air cylinders.

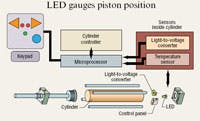

Engstrand developed InSight, a sensor that fits in the end cap of an air cylinder and requires little more than a drilled and tapped hole. The sensor contains a light emitting diode (LED) and light receptor. The LED transmits light into the cap end of the cylinder, and the reflected light picked up by the receptor indicates the relative position of the piston. As the piston rod extends, the reflected light picked up by the receptor decreases.

The complete sensor also consists of a control module that is external to the cylinder. This module contains the microprocessors necessary to regulate power to the LED and condition the feedback signal from the receptor. It also contains a small touchpad control panel for programming the sensor and an LED readout of piston position.

Programming is simple. The operator extends the cylinder’s piston rod to its first end position, then pushes a button on the sensor’s control module to lock in the position. Next, the operator retracts the piston rod to its second position, pushes a second button on the module, and locks in the second position. To program a new position, the operator simply extends or retracts the piston rod, then presses the appropriate button.

The InSight sensor can also be incorporated into controls that would automatically shift the cylinder’s directional control valve when the piston reaches a switching point. And because the sensor provides a continuous output signal, it could, conceivably, be used in a servopneumatic positioning system.

Illustration shows major components of tie-rod cylinder and Insight sensor.

Select for full image

Engstrand, however, has his sights currently set on replacing reed switches in air cylinders. He said his technology is much more suited to automation systems than reed switches are, and for about the same price. He explains that his breakthrough was developing an LED light source that compensates for temperature. “As an LED heats up or cools down — even slightly — it’s light output varies substantially. This would prevent being able to determine piston position from reflected light within a cylinder, Engstrand explains. “But my patent covers a technology that stabilizes the LED’s output, regardless of temperature. The LEDs and receptors are so inexpensive that the entire sensor system is cost competitive with systems currently running with reed switches.”

Limitations and opportunities

Engstrand points out that any cylinder using his sensor must be supplied with clean, dry oil-free air to prevent introducing variables that could interfere with the reflection of light within the cylinder. This means if the piston is attached to the rod with a piston nut on the cap end of the piston, the cylinder must have a non-rotating piston rod. Otherwise, light reflected off the flat sides of the nut would reflect light according to the angular position of the rod. Engstrand circumvents this limitation in his company’s cylinders by threading the piston rod into the rod end of the piston. This eliminates the need for a piston nut on the cap end of the piston.

Also, because oil and dirt can collect on the inner surfaces of the cylinder, clean, dry, unlubricated air must be maintained. However, if readings should drift over time, the sensor can be recalibrated simply by positioning the piston rod to the end position and pushing the appropriate button.

“But the InSight isn’t limited to being only a piston position sensor,” continues Engstrand. “The technology can be applied wherever light can be used as an inexpensive measuring tool. For example, the millions of smoke detectors in use around the world all rely on a radioactive material to detect specific characteristics of ambient air to determine if smoke is present.

“An LED and receptor can do the same thing, and at a far lower price. And with the current trend toward increased environmental awareness, eliminating the need for radioactive materials makes the InSight an attractive alternative, even if it were to cost more, but it costs less. So I expect the technology to be applied to many other fields. But for now, I’m just focusing on replacing reed switches.”

For more information, contact Motion Controls LLC at (262) 673-9255, or e-mail [email protected].