Forest products manufacturers must generate profits from whatever logs are available — even if they are of lower quality than in years past. Therefore, mill operators look for machinery that automates the process of optimizing log yields, and the manufacturers of the machines are looking to make them smarter and more flexible than ever before.

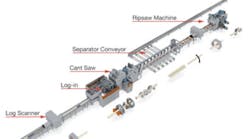

The Veisto Group, of Mantyharju, Finland, is a private, family owned company with roots deep in the Finnish forests. The experience of many generations has taught them how forests can be utilized economically, ecologically, and profitably. This sawmill machinery manufacturer is committed to leading the way in automating the log breakdown process and serves saw mills globally. The company’s compact sawing lines are designed to perform all of the processing steps, from handling of raw logs through production of made-to-measure finished lumber, in a single processing pass. The lines typically consist of two or more sawing units, conveyers, and log positioners. They have integrated edging capabilities to square up log surfaces, so separate edging devices are not required. In addition to finished lumber, Veisto’s HewSaw product lines simultaneously produce top-quality pulp chips.

Coordinated processes

Four processing stages typically occur in a HewSaw line:

• log infeed/scanning and optimization/ orientation,

• four-side chipping and controlled curve sawing,

• side board optimization and edging, and

• double arbor rip sawing and optimized edging.

In the optimization stage, a computer performs three-dimensional modeling of each log, selecting the best cuts by trying thousands of combinations of log orientations and cutting patterns to achieve the best value from each log. Based on a new set of computations made for each 50 mm along the log, the optimizer produces target positions for all of the hydraulic actuators that guide each log as it moves through the machine. The motions of the actuators that dynamically steer the logs through the chippers and saws, and the actuators that dynamically position the saw blades themselves need to be geared to the speed of the feed chain that transports the logs. Maximum yield usually results when the log is cut along the grain, which may have a curve. Cutting curved logs along their curves is an improvement over the old practice of always making straight cuts, which resulted in losing wood at the ends of curved logs, thereby yielding shorter boards.

A tightly integrated processing line, such as Veisto Group’s HewSaw system, requires a lot of coordination between the sequential process stages. Some of the more complex saw lines can involve several dozen motion axes that need to be controlled. Individual machine stations can involve as few as two axes, whereas other stations, such as the curve saw, can employ between five and eight axes.

Besides higher yields, another advantage of tight synchronization of the motion is the ability for the HewSaw machines to be physically oriented in a straight line, using much less floor space than other saw lines. This makes it easier to keep track of the wood and reduces facilities and maintenance costs.

Matching controls to the application

From a technical perspective, the motion controllers must excel at closed-loop control of hydraulic systems. Hydraulics is the power of choice for applications such as the HewSaw machines that involve positioning and moving heavy loads. It’s not enough to simply move heavy axes, however. To extract maximum productivity out of a hydraulically-operated machine, the axes must be moved with precise closedloop control.

So how does a manufacturer such as Veisto select motion controllers for use in their machines? “We have several criteria for selecting motion controllers,” said Petri Palo, Veisto automation engineer. “One of the main ones is user friendliness from a design perspective. Because we use so many of them in different ways, the controllers must be easy to use, and the vendor’s customer support must be very responsive and efficient.”

Beyond closed-loop control, implementing a highly productive and compact integrated saw line requires the synchronization and gearing of multiple simultaneous operations. All of the machine’s motion must be coordinated in order to allow an operation’s line speed to be varied for handling different grades of input logs (lines processing soft wood can run faster than those processing hard wood) without creating bottlenecks or machine maintenance problems.

“We looked at different programmable electronic motion controllers and decided to standardize throughout our product lines on the RMC family of motion controllers from Delta Computer Systems,” said Palo. “The different models offer a range of performance and capacity with a common easy-touse development environment.”

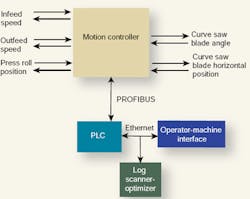

For machine stations that involve only one or two motion axes, HewSaw uses the RMC75. For machines that control more axes, the company uses the RMC150. To provide supervisory control of the entire line, HewSaw systems use a Siemens PLC. The PLC communicates with the motion controllers over PROFIBUS, an internationally-recognized industrial fieldbus standard.

Optimizing yield

The block diagram of a typical HewSaw curve saw illustrates that the motion of five axes needs to be coordinated in order to ensure that the saw blades precisely follow the curvature of the log. Information on the positions for each axis is passed from the log scanner-optimizer to the PLC. Those values are then converted into a sequence of instructions for the motion controller. Because each log is different, the exact operations performed by the motion controller will differ from log to log.

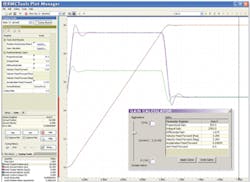

Part of the machine development process is tuning the motion to optimize how the machine works. To simplify this task, Delta Computer Systems motion controllers are provided with software called RMCTools that enables the user to graphically display the motion of any of the system’s axes versus time. The graphs compare the actual motion of the system with the system’s optimal target motion, and when the motion is tuned perfectly, the actual and target motion curves overlap.

To simplify the tuning process, RMCTools includes an automated Tuning Wizard that allows designers to tweak control loop gains via a slider bar on the screen. “Delta’s software tools make design optimization very straightforward,” said Petri Palo. “The plot manager graphs really speed up the tuning process.”

The new mill products from HewSaw have seen success across the globe. Installations process materials as diverse as eucalyptus in Australia, fir and spruce in Canada, and pine and spruce in the company’s Scandinavian home country. The company has gained a reputation as one of the most technologically advanced sawmill equipment providers.

“We owe a lot of our technical success to the support that we’ve gotten from Delta and its Scandinavian Distributor SKS Control Oy,” concludes Palo. “It’s a long way from Delta’s headquarters in Battle ground, Wash. to Finland, but they respond as though they were located next door to us.”

For more information on motion controllers from Delta Computer Systems, Inc., visit www.deltamotion.com.