Sensor detects piston position in accumulators

Whether they use a piston or a bladder, accumulators are all about precharge pressure. When sizing an accumulator, specifying the correct volume and precharge pressure can mean the difference between a system that runs smoothly and efficiently, or one that is plagued with problems. Mac Stuhler, VP at Control Products Inc., East Hanover, N. J., explained that monitoring the precharge pressure of a bladder accumulator is fairly straightforward: install a pressure transducer to detect the pressure of the precharge gas in the bladder.

Stuhler revealed that piston accumulators pose a different scenario. Because piston seals are dynamic, they are subject to wear and eventually will leak. This can cause the piston to drift, so even though a pressure transducer may indicate the correct pressure, the piston may not be where it should based on the pressure. If the piston is too close to the end cap, then a sudden increase in system pressure could cause the piston to slam into the end cap — certainly a dangerous situation. For this reason, designers often specify an accumulator with a longer stroke than necessary to provide extra length in case the piston has drifted.

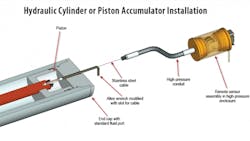

To address these challenges, Control Products introduced three sensors that detect the absolute position of pistons in accumulators (and hydraulic cylinders, too). Control Products’ SL series sensors use a stainless steel cable that enters the accumulator though an SAE size 8 fluid port and attaches to a 7/16-20 hole machined into the piston. The cable is connected to an LVDT that provides a continuous and absolute analog or digital output signal indicative of the piston location using non-contact sensing technology.

Stuhler said the SL’s sensor works on the gas or fluid side of the piston and alleviates issues associated with rod-type position sensors.

The SL sensor is available in three standard sizes:

• the SL390 accommodates strokes to 1 m;

• the SL1200 measures strokes to 3 m;

• the SL1400 handles strokes to 7m.

For more information, call Control Products Inc. at (973) 887-9400, email [email protected], or visit www.cpi-nj.com.