Closed-loop control accelerates car wheel testing

Structural durability testing in the laboratory replicates damage or wear out scenarios seen in real life. In applications where the forces and frequencies are high, servo hydraulic power is often the best method with which to reproduce field data.

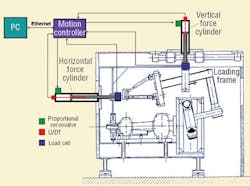

For example, Innkeeper LLC, Redford, Mich. developed a system for testing automotive wheels by applying forces in two axes simultaneously, or biaxially, using servohydraulic cylinders, Figure 1. This method provides a significant improvement over traditional single axis wheel testing methods and is used to discover which wheel designs will survive without failure once attached to a vehicle. In this system, one hydraulic cylinder applies a radial (vertical) load to the wheel as it spins at freeway speeds inside a moving drum. A second cylinder simultaneously applies a lateral (cornering) load to the wheel.

Other wheel test machines apply force to only one axis at a time, but based on 40 years of combined experience, Innkeeper’s engineers believe that only by testing wheels with cornering stress and vertical stress simultaneously can a truly realistic durability test be performed.

By recreating the most stressful driving conditions on the wheel under test, the machine is able to accelerate the wear and tear seen in a lifetime of road use. Innkeeper’s test system can impart structural stress equivalent to 150,000 mi of road use in 3½ days. Obviously, this accelerated testing saves the vehicle and wheel manufacturers a significant amount of time and money compared to on-road or track testing.

Summing up the challenges

The challenge for controlling the servohydraulic cylinders within the test system is that there is always interaction, or cross coupling, between the two axes while in force control. Applying a lateral force through the machine imparts both a lateral and radial force component into the wheel. These forces change due to the angular relationship between the wheel axis and the machine axis, Figure 2. The angular relationship between these two axes changes constantly and, as a result, commanding and holding a steady force is like shooting and hitting a zigzagging target.

Flexibility is also important. When car or truck companies come out with new vehicle designs, they will have new wheels as well. Hence, the test machine needs to be highly adaptable to applying new testing protocols.

Innkeeper’s biaxial test machine was purchased “used.” The documentation for the machine was half in German and half in Czech. The main control computer was a Windows 98 vintage PC with ISA slots — and it wasn’t upgradable. This presented problems right out of the crate.

To make matters worse, the control computer’s mother board was damaged in shipment and could not be repaired. John Gagern and Kevin Kretschmann, Innkeeper’s principal owners, found a replacement for the 14-yr old motherboard, but it wasn’t easy. “This demonstrated a definite need to find a replacement control system, and fast,” said Kretschmann.

One or two high end, “off the shelf” servocontrollers might have been used to control the motion. Typically, though, these controllers are expensive and the operator invariably has to adapt the test method to accommodate the controller’s existing software front end.

Search for a solution

Innkeeper considered options such as these high end controllers (both new and used), PC-only software control solutions, and popular motion control hardware modules with software interfaces. However, Kretschmann couldn’t find the right balance between cost, quality, and performance. “We could find a reliable solution with good control loop response for our application, but the cost was prohibitive,” he said. “The other solutions sacrificed either reliability or performance. What I wanted was a low-cost servo controller to implement a closed PID loop in hardware and a graphical user interface built specifically for our application.” His search led him to the RMC151 electrohydraulic motion controller from Delta Computer Systems Inc.

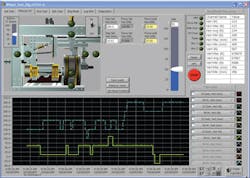

“The advantage of the Delta controller is that it’s built specifically for closed-loop control, as opposed to other control hardware that can also do closed loop, explained Kretschmann. “It is a blank slate — you can design any control that you can imagine. Once I had the PID loops programmed and tuned the way that I wanted them, all I had to do was build the front end operator interface on the PC. For this, I leveraged the Delta controller’s ability to tie in through Ethernet to the PC running LabView, Figure 3. Delta’s RMCLink software package includes LabView-compatible virtual instrument controls that can be used to initiate and control motion profiles.”

Another characteristic that gives the Delta controller an advantage for controlling hydraulics is its ability to control both the position of hydraulic actuators and the force that they exert — and, importantly, to switch smoothly from controlling position to controlling force. In the case of the Innkeeper system, position control is used to place the wheel into the drum. But during actual test runs, the cylinders are operated solely under load (force) control. With the Delta commands, it’s easy to move from position to load control. According to Kretschmann, the mode switching takes place in the background, and the machine operator doesn’t even notice the switch in control modes during operation.

To tune the motion control loops, Kretschmann used automatic tuning software provided in Delta’s RMCTools software package for position control. He also used Delta’s graphical tuning tools, including the company’s Plot Manager Software, to fine tune the force control loops.

The Delta RMC151 controller is also easy to “drop into” the system from a hardware standpoint (see Figure 2). The controller was able to use the same position and force sensors that originally came with the wheel testing system. For position sensing, both hydraulic cylinders have linear variable differential transformers (LVDTs) built into their piston rods. The LVDTs are electromechanical transducers that convert linear motion into a corresponding electrical signal.

All Kretschmann needed to do was condition the LVDT outputs to match the ±10 V range of voltage inputs required by the Delta RMC. For controlling the force exerted on the wheel by the hydraulic cylinders, the existing load transducers were interfaced to analog inputs on the RMC. Finally, for control outputs, the RMC controller was interfaced to the same servovalves that came with the machine. Kretschmann needed to add voltage-to-current converters to connect the motion controller to the valves, but that’s all that was needed to make the machine work.

Ease of programming

The simplicity of programming and system connections makes the Delta controller easy to service. All the main components are standard off-the-shelf items. “With the Delta controller in use, almost any qualified electrical technician can service it,” explained Kretschmann. “The troubleshooting logic is similar to what plant electricians are already qualified to do.”

“From a retrofit standpoint, the Delta controller is extremely cost effective,” said Kretschmann. “I estimate that retrofitting the controls in our old machine cost only about 25% of what a new machine or a custom-designed servohydraulic system would have cost. And shortly after we completed this project, we received an order to perform two machine control retrofits for a different customer (in Germany). The Delta controller is flexible. Obviously, it’s good for use in applications that we find in the automotive industry, but we plan to use it for retrofit applications in other industries as well.”

To see a video of this system in action, click here.

For more information, contact the author at [email protected], or visit www.deltamotion.com.