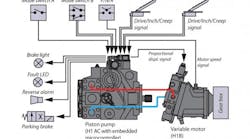

Sauer Danfoss' Automotive Control solution incorporates an H1 variable-displacement piston pump with embedded electronic control, H1 variable-displacement bent-axis piston motor, sensors, and associated HMI devices. Click on image for larger view.

Combined with software, AC provides an automotive style automatic transmission driving experience that allows operators to adjust hydrostatic transmission characteristics to suit specific operating requirements.

Safety and easy installation

An H1 AC embedded controller is mounted directly onto the pump, and all electrical connections are located for easy OEM vehicle installation and sensor calibration. The embedded controller also features additional “watch dog” circuitry, which provides real time fault monitoring of the electronic hardware.

“The H1 Automotive Control is the first solution on the market to offer the precision and consistent performance of intelligent electronics combined with complete drive system functionality, system qualification, and SIL 2 certification,” said Joseph P. Maher, system portfolio manager. “OEMs will be able to reduce time to market for new vehicles and model variants while still customizing vehicle behavior and providing differentiation for their products.”

The H1 AC software can be configured to OEM requirements and protects against engine stall and over-speed, extreme high and low hydraulic oil temperature, and hydraulic motor over-speed. In addition, variations in hydraulic oil viscosity affecting control performance are compensated for automatically. The result is consistent, predictable vehicle performance irrespective of operating temperature.

Functionality and customization

The H1 AC is customizable via the Plus+1 Service Tool between four operator selectable system modes that can be programmed according to three main propel methods or mode types.

Automotive Mode — Hydrostatic pump and motor displacement are controlled automatically according to an OEM configured automotive curve as a function of engine speed. Typically, it is used for vehicle transport or to provide engine anti-stall functionality during heavy load conditions common on wheel loaders, telehandlers, or site dumpers.

Non-automotive mode — Hydrostatic pump displacement is controlled directly through a foot pedal or joystick input from the operator and is independent of engine speed. It is generally used when a specific engine speed setting is needed for work functions common on sweepers, snow blowers, or mowers.

Creep-automotive mode — Pump control is provided by an algorithm that combines both engine speed and foot pedal or joystick inputs. Benefits include the ability to customize hydraulic pump and motor displacement profiles and ramp times, provide constant speed drive functionality, and interface to vehicle systems via CAN, and easy-to-use diagnostics.

System modes are selected through switch settings on the vehicle and allow OEMs to configure working and driving modes or tailor driving behavior to suit specific working conditions or the skill levels of operators. The OEM can use the same hardware for a range of vehicles with different software settings, significantly improving vehicle manufacturing flexibility.

For more information, call Sauer-Danfoss USA at (515) 239-6000, or visit www.sauer-danfoss.com.