Electro-hydraulic Motion Controller Enables Precise Automotive Tester

In automotive component stress testing applications, perfectly-tuned hydraulic systems are often essential to providing reliable, repeatable results. One developer of special purpose machines for assembly, fabrication and testing of automobiles is Suyash Engineers & Automation Pvt Ltd (SEAPL) of Pune, India. They are a supplier to the Tata Motors Ltd. Engineering Research Center, a unit of Tata Motors, India's largest automobile manufacturer. The Engineering & research Center deals with prototype development and testing activities.

Since the company’s founding in 2003, SEAPL has designed and manufactured several test benches and servohydraulic test rigs running up to 10-kHz frequencies for:

- Lateral runout testing of automotive brake disc assemblies

- Hub bearing endurance testing

- Leakage testing machines for cast liners and pump casings

- Endurance and durability testing of lift axles

- Endurance and durability testing of leaf springs and suspension

SEAPL has used different controllers to operate their test systems over the years, from various local and foreign sources. Many of their test systems have used PCI-, PXI-, and PCIE-compatible interface hardware to connect with PCs running National Instruments’ LabVIEW software for data logging and analysis. The platform changes were necessary because the systems often provided less than satisfactory results.

“We were facing problems like inaccuracy in position and load, sluggish response, the need for frequent re-tuning of PID parameters, complications in programming logic and so on,” said Sujay Wayse, SEAPL Managing Director. “To eliminate all the above problems and to bring the desired accuracy and precision in testing we thought about packaged solutions from big name industrial control companies like MTS, Instron and Moog, but frankly speaking, they were too expensive and we wanted to integrate the test rig with our own architecture and component selections.”

A recent project gave them the opportunity to develop a new solution. SEAPL was asked to develop a system for testing leaf spring suspension assemblies to be used in a wide range of utility vehicles, from small trucks to heavy trucks. The system needed to perform fatigue/endurance testing of various springs under simulated road conditions in order to verify spring quality and provide the manufacturer with information on the component life cycles. To ensure that road conditions are being modeled exactly, load data was acquired during rigorous road testing and then the same loading is applied precisely to the suspension assemblies under test for a specified number of cycles.

The response of the spring force is logged to learn the component failure point, to measure hysteresis in deflection or load as the test progresses (which can be an early warning of impending component failure), and to also know the initial stiffness and change in stiffness after a certain number of cycles (which is also an indicator of component quality). Therefore, the system needed to not only apply a predetermined amount of force and count the cycles, but it also needed to be able to monitor precisely how the test specimen responds to the force. The tester does this by measuring the deflection of the spring that occurs each cycle,

In light of the problems that SEAPL had with other hydraulic controllers, they sought out a new solution to control the hydraulics of the leaf spring tester. “We had a pretty good experience with a controller manufactured by Delta Computer Systems when we were working with a servohydraulic compression molding press in 2002,” said Sujay Wayse. “So we searched for Delta motion controllers on the internet and contacted the company to receive more information.” The controller that they selected was an RMC75E two-axis unit (Figure 1).

To complete the spring test system, the RMC75E controller was paired with the following system components: To apply the force on the leaf spring under test, SEAPL manufactured a 1-tonne servohydraulic cylinder with ±100 mm stroke. To control the cylinder, it was important to use a proportional servovalve so that different amounts of fluid can be metered out to the cylinder, allowing for very precise force to be applied to the specimen. For this task, SEAPL selected a 170 lpm unit manufactured by Atos SpA. To measure the displacement of the specimen, the company chose a 200mm LVDT from Gefran SpA. To measure force, the system uses a model 15T load cell from ADI Artech. The completed test system is shown in Figure 2.

The LabVIEW front end software application (Figure 3) was hosted on an Advantech industrial PC, which was connected via Ethernet to the RMC75E. During a test sequence, the PC downloads the motion instructions to the motion controller and then the PC reads force and position information from data registers in the motion controller as the test proceeds. Delta Computer Systems’ RMCLink software is used to enable communication between the PC and the motion controller.

“The installation and commissioning of the Delta RMC75E was really one of the best experiences for us,” said Sujay Wayse. “Because the controller interfaces directly to servo valves and transducers, putting the system together is virtually ‘plug and play.’ After some configuration, the test rig started running the very next moment.”

“The Auto tuning feature that is supported by Delta’s RMCTools software was the most exciting thing in commissioning,” continued Wayse. “Our past experiences with other controllers were bitter enough, but tuning with the RMC Software was done in a matter of minutes.” Delta’s AutoTuning software computes a system model that accurately represents the system during its normal operation, and then calculates the gains for the P, I and D and Feedforward gain terms in the control loop equation. The software provides a slider bar that the user can use to adjust the P, I and D gains to vary the “stiffness” of the system response.

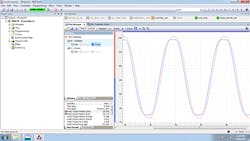

As the motion control parameters were changed and the tests re-run during the development cycle, the SEAPL engineers would plot the motion using the Plot Manager provided in Delta’s RMCTools software package. When the “actual position” curve precisely overlaps the “target position” curve, then the motion is tuned precisely.

The new test system has met all of SEAPL’s requirements. “Since our leaf spring test system was developed, we have completed 500,000 trials using a test cycle frequency of 0.5 Hz and spring displacement of ±76 mm, with a positioning accuracy of ± 0.5 mm, achieved as per specification,” said Sujay Wayse. “And our load accuracy of ±50 kg over a full testing range of 8,000 kg is achieved and is well within allowable limits. Overall, our experience using the Delta controller has been wonderful. It made our life easy.”

“Our next project consists of simulating the vehicle suspension under road load conditions with four actuators,” said SujayWayse. “It will require the synchronization of simultaneous multi-axis motion, and for that project we will likely use the Delta RMC150 eight-axis motion controller.”

Rick Meyerhoefer is Regional Sales Manager at Delta Computer Systems, Battle Ground, Wash. For more information, call (360) 254-8688, or visit DeltaMotion.com.