More Than Just Air: Advances in Pneumatic Valve Control Technology

The automation industry is rapidly introducing and mainstreaming many production systems aligned with concepts for the internet of things (IoT)—intelligent, networked production systems, and components that enable interlocking manufacturing platforms that leverage smarter information and communications technology. As this evolutionary process builds momentum, pneumatic technologies (especially control valves) continue to evolve and incorporate sensors, machine bus interfaces, and complex digital control features that make them well-suited for use in emerging IoT-driven production systems.

Aventis AV03/AV05 valves (top), integrated with the AV03-EP electropneumatic pressure regulator (bottom), deliver pressures that can be reproduced and documented at any time. A machine’s PLC sends values via a fieldbus or a real-time Ethernet protocol—such as Profinet IO—to the valves’ electronics, which support all conventional protocols.

Evolution of Valve Control Technology

Control of pneumatic actuators and cylinders was originally done through discrete wiring, with each device wired to a solenoid and triggered separately. This configuration was usually expensive and time-consuming to install. It also required a host of output blocks on the system’s programmable logic controller (PLC).

This evolved into a more manageable solution, with the creation of plug-in manifold valves connected to the PLC with a single multi-pin connector and typically wired into terminal strips; this began the process of reducing the wiring for control purposes. Although these manifold valves helped reduce parts and labor costs, they did not initially incorporate feedback or other operational information in the valve spool actuation itself. Capturing that information required parallel sensors wired through I/O blocks to measure and verify correct pressure and the cycling of cylinders, or other actuators through their motion sequence.

As automation systems became more sophisticated, fieldbus communications connectivity was implemented, using a variety of protocols such as Profibus, Sercos, and Ethernet-based backbones. Pneumatic valves began incorporating both fieldbus interfaces and I/O interfaces to provide complete pneumatic valve packages that were more versatile and engineered to be integrated easily with smarter, more sophisticated automation platforms.

The integration of these communications components, along with the introduction of lighter-weight materials for construction, mean valve manifolds can be placed closer to the actuators they control. Machine builders can install valves on end effectors, robot arms, and other working components. Besides decreasing the amount of tubing needed to connect the valves and cylinders driving the equipment, this can reduce potential leakage in the system, as well as leading to quicker response times and increased throughput for motion sequences.

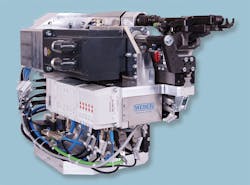

Generating pressure changes dynamically based on a target/actual value comparison on the output side, the Aventics AV03 advanced valve system with integrated electropneumatic pressure regulation is a key element in flow drill screw systems from Weber Schraubautomaten. (AV03-EP version without LED display used in this application.)

Integrating Electropneumatic Pressure Regulation

These advances in valve performance and versatility took a major step forward with integration of electropneumatic control capabilities into the valve manifold. A basic pneumatic valve is just a simple, directional control valve: An electric signal is sent to shift the valve spool, and the air is directed out of one port or the other. Electropneumatic pressure regulating valves, also called E/P valves, can provide a range of pressures, up and down a linear scale, based on the signals the device receives.

The original analog versions changed the pressure based on an analog scale of the signal, providing a linear output pressure to the cylinders or other end-effectors according to the linear analog input signal. With the capabilities offered by digital E/P valves and fieldbus connectivity, the electropneumatic pressure control within the system is much more sophisticated: The machine’s PLC can send pressure parameters to control valve and cylinder pressure much more dynamically as part of the motion control programming for the production system.

This advanced level of pneumatic control—intelligently combining both directional and pressure control—elevates the value and versatility of pneumatics for a wide range of automation applications. It allows for greater, more precise control of movement in production process requiring good endpoint accuracy and repeatability.

For example, an Aventics electropneumatic control is used in welding systems for automated manufacturing of engine starters. In this example, a pre-mounted armature is transported on workpiece pallets, aligned for position detection and brought into position for welding by pneumatically-driven grippers. After welding, more grippers return the armatures to workpiece pallets and transport them to the next production step.

Electropneumatic pressure regulators, combined with an advanced valve manifold with integrated communications bus, optimize the diffusion welding processes with dynamically controlled pressure that can be precisely tailored to the application. At the same time, intelligence built into the manifold monitors and documents all of the valve’s functions, controlling the grippers for an enhanced level of quality control and process tracking.

An added advantage of using digital E/Ps is the ability to optimize energy efficiency by supplying only the required pressure to perform a specific task, rather than using the highest pressure for all tasks. For example, an application may require a cylinder to extend at 80 psi, but retract at 30 psi to save energy. Using digital E/Ps, the machine builder can program these parameters into the system.

The integration of communications components, along with the use of lighter-weight materials for valve manifold construction, make it possible to locate manifolds closer to the system or actuators they are controlling, enabling machine designers to reduce the amount of pneumatic tubing needed.

Enhanced Monitoring and Control

One of the key goals of IoT manufacturing is more sophisticated control of every single step in a production process. Machine operators building components for cars, for example, need to know the precise force, pressure, and position of a cylinder driving an actuator that’s pressing a bearing into a housing . . . and they want that sequence documented so they know that 50,000 parts later, it was manufactured with the exact same precision as the first part off the line.

Any deviation in the data points generated by pneumatic components as they operate can indicate issues with the actual valve or actuator. It can also indicate other issues: pressure loss in the air supply system, the bearings placed being out of tolerance, or valves or cylinders succumbing to seal degradation.

The intelligence built into pneumatic valve technology provides new opportunities for that kind of monitoring and control. If a valve is rated to provide a proper operating life of 120 million cycles, when it reaches 100 million cycles, a well-designed predictive maintenance system can capture and use that data to either conduct a diagnostic inspection or implement an automated purchasing request for a replacement device.

With IoT-enabled valve manifolds, a system can be engineered to easily and seamlessly supply different pressures for different tooling positions and sequences for flexibility, including support for on-the-fly pressure changes and tooling positions for quick product variations for changeovers.

As pneumatic components become more intelligent, they generate additional data points across the production systems where they are used—statistics, diagnostics, and lifetime data. These data have the most value when used to manage production systems more efficiently, control energy consumption, and maximize uptime. However, all this data from pneumatics—as well as other intelligent machine drives, devices and subsystems—have the potential to overwhelm the machine control bus and complicate automation command and control performance.

Some pneumatic component manufacturers, such as Aventics, are offering smart pneumatic monitoring gateways (hubs) that aggregate and organize pneumatic performance data and deliver it through separate, parallel pathways to plant management systems. These hubs can be independent of the process control architecture, using OPC UA, MQTT, FTP or e-mail pathways to deliver alerts and both system-level and device-level performance data.

IoT-enabled pneumatic valves also now incorporate features and valve technology that provides a new level of precision control for pneumatic-driven actuators and armatures. Due to more advanced electronics within valve control modules, these valve manifolds can now incorporate PID (proportional integral derivative) controllers for pneumatic positioning applications that automatically apply accurate and responsive correction to a control function.

With these pneumatic capabilities, not only is it possible to provide more precise motion system endpoint accuracy, but in conjunction with the motion control programming in the PLC, it’s possible to switch from position control to force control in real-time and fine-tune motion sequences for very high levels of automation, product throughput, reliability, and repeatability.

Smart pneumatic monitoring hubs collect and organize pneumatic performance data and deliver it through separate, parallel pathways to plant management systems, independent of the process control architecture, to deliver alerts and system-level and device-level performance data.

Smarter Pneumatic Valves for the IoT Era

Pneumatic valves have been steadily evolving to help OEMs and end-users make full use of pneumatic technology in their automation systems. In addition, many pneumatics technology providers have substantially upgraded their online configuration and ordering systems to make it both efficient and easy to get the components machine builders need on short turnarounds.

These systems simplify what, at one time, could be a time-consuming process of ordering multiple elements—sub bases, mounting equipment, and cabling, as well as the valves themselves—in order to purchase a complete assembly. Now, these online configurators make it easy to order one valve assembly—selecting the fieldbus interfaces, integrated I/O modules, and other features—with CAD drawings included as part of the package. This will enable both OEMs and end-users to get a complete configuration in a condensed and more reliable purchasing process.

Leveraging the power of both electronics and modular, cutting-edge industrial design, pneumatic valves as part of complete, intelligent pneumatics motion and control platforms provide a proven, cost-effective and versatile technology option for a wide range of IoT automation and manufacturing applications.

By working with pneumatics component providers who continually invest in improving their technology and have the insight to help machine builders take full advantage of the potential pneumatics offers, machine builders and end-users can be confident their systems will have the versatility and sophistication to satisfy current and future manufacturing requirements.

Marchelle Forish is senior product specialist—controls at AVENTICS Corp., Lexington, Ky.