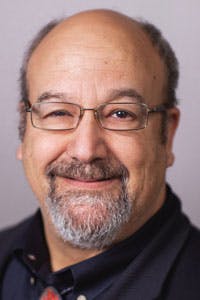

“Books on maintenance are really boring,” said Joel Levitt.

His comment is not the sort of declaration one expects from a veteran author of more than 19 maintenance management texts, as well as the president of Springfield Resources .

But the statement, it turns out, is partly in recognition of another factor in the maintenance discipline: New methods of learning to diagnose root causes of failure are emerging, and the skill set needed to perform maintenance tasks rests on the interests of the next generation.

Levitt's most recent work, Elements of Great Maintenance Management, is in fact a series of graphic novels based on the fundamental concepts of maintenance that are designed to teach the basics. Instead of a wordy textbook, her elected to entertain readers with a compilation of colorful comic books, each injected with a dose of industry-specific humor. The series includes The Quest for Defect Elimination, The Battle for Reliability and The Stories of PM (Preventive Maintenance).

“I have young adult sons and they wouldn’t pick up one of my books if I paid them,” quipped Levitt. “But when I made it into a comic format, they said, ‘Oh, let me see it.’ It was exciting and I realized that young people aren’t interested in heavy tomes. They’re more interested in ‘let’s get the information, let’s get it fast, let’s get it entertainingly.”

Despite the next generation’s appetite for new technology and instant gratification, the long view is that there’s no quick replacement for tried-and tested tenets of good maintenance practices, said Levitt, who has trained more than 17,000 maintenance leaders from 3,000 organizations in 39 countries.

In the following interview, Levitt shares insights on contemporary approaches to defect elimination, the concept of world class maintenance and how the education of maintenance and reliability professionals is evolving.

Rehana Begg: Your comic book series is a great introduction to the disciplines of maintenance and reliability, particularly if you’re not technically inclined. The illustrations make it easy to start learning about the concepts. Let’s focus on “defect elimination” for a minute. My understanding of defect elimination is that it revolves around pinpointing a defect and then implementing corrective action to prevent future failure or events. So, it’s about fixing the source of the recurring bearing failure, for example, as opposed to fixing the failure over and over again. What is your layperson’s description of the difference between planned maintenance activities and defect elimination activities?

Joel Levitt: The way we look at defect elimination is that it’s run as small projects. It could be a 15-minute project. Although, we put it in the CMMS (computerized maintenance management system)—in a corrective maintenance work order—to gather the time [element]. It doesn’t have to be so fancy, and it could be really, really straightforward [tasks] that take minutes to do. A defect is anything that reduces the value of an asset, such as, when it reduces the output, or reduces the capacity.

It could be something really, really little. I got this from Winston Ledet, who’s a great thinker in this area. His thing was that you’ve got a pool of defects in your plant. Whether it’s instrumentation or mechanical, there are defects, like loose screws. He says, if you spend a little bit of time every day dealing with that, in addition to your workload, all of a sudden, the pool gets shallower…That’s defect elimination.

Planned maintenance is a defect found by PM inspection and then planned and scheduled. So that could be quite a large job or it could be something more subtle.

When I think of defect elimination, I liken it to walking around the house and picking up stuff that you could trip over.

RB: Can you give an example of a problem that you’ve seen maintenance professionals come up against time and again? Why does it keep recurring?

JL: There are actually two things going on. I was at a power plant in California and we walked past a steam trap that was blowing steam. We must have walked past that steam trap 12 times while were looking at the other bigger things. That’s a defect that, if you fix it, you don’t have it anymore. It’s a kind of a mental attitude where we normalize the deviance. In other words, you say, “Oh, we have leaks. Too bad.” That’s one part of it.

The part you’re talking about is super-important. The process is root cause analysis, where we try to figure out what is going on that causes that. The truth is, a lot of maintenance folks actually don’t mind stuff that break over and over again. They know exactly what to do and it’s this feeling of mastery: “Oh yeah, I’ve done that 22 times before.” But we really want to activate their brains and get rid of [defects] permanently and move into a new domain that wasn’t even there before because we had so many defects.

RB: Can you comment on the cost implications of doing this well?

JL: The thing that always impressed me about maintenance is that the cost of maintenance is dwarfed by the cost of downtime for the thing you’re maintaining. I go in and I have a pump that’s part of my process and it cost me $1,700 to fix the pump. But the amount of production I lost was $50,000. So, the cost implication—and this is really funny, because the gains you get from defects elimination and plant maintenance don’t show up on the maintenance budget. In fact, the maintenance budget may even go up a little bit because you’re using more parts. But the really big benefit is going to be in the operational budget or the production budget.

RB: Your book, Managing Factory Maintenance, dates back to 2004?

JL: 1996 was the first edition.

RB: A lot has changed since then. We’re on a digital journey, and we’ve talked about the changing of the guard in maintenance for decades. Can you speak to the fundamental shifts in maintenance theory and management, then and now?

JL: Well, it’s funny because the shifts are really recent. And it’s something that old people like myself remember, when there was this idea of using computers. I have a degree in computer science. I was involved in computerization of maintenance in the late 1970s and early ’80s. So, this was with mainframe computers and CICS, COBOL.*

The data structures that we used in those days are virtually unchanged in Maximo or Infor or the big systems now. That’s kind of interesting that 40 years later, the data structures are the same. But where there’s the huge difference is in the use of analytics and AI to utilize the data more deeply. And this is a Brave New World for maintenance. Big Data is nothing new. But the idea of having all the maintenance data, all the operational data, the weather, everything in a database linked by time is awesome. That’s really the way maintenance has been conducted.

I go back to Rome: building the roads through Europe and the way they maintain those roads. They used the basic same PM structure that we use now…George Washington told the troops here in the United States to make sure that they clean their weapons, because if they don’t work, you could die. So that’s all the same as it’s always been. But this idea of looking at the data and then having an incident, and then looking back from the incident through the data to see what changed, and then being able to have a prescription for the change in the future—that’s really new and very exciting.

*Editor’s note: COBOL is common business-oriented language, while CICS, or “customer information control system,” is middleware located between the z/OS IBM mainframe operating system and business applications.

RB: Here’s one other concept that comes up time and again—and it’s evolving. The concept of “world class maintenance” has been visited and revisited. The idea is to develop a method for comparing how an organization compares to industry standards. Organizations are now more reliant on predictive maintenance. How would you define world class maintenance today, given that we’ve just discussed our trajectory into AI and digital transformation?

JL: I’m not of the opinion that world class maintenance exists. You can’t look at something and say this is world class maintenance, because what would be world class maintenance in a steel mill would not be world class maintenance in a pharmaceutical plant. The business requirements are so different.

In fact, if you tried to run pharmaceutical-level maintenance in the steel plant, you would instantly go under. So, where I come down on world class maintenance is that it is aspirational domain. It’s something we’ve looked towards—like trying to be good in the Christian sense of good. People use it as a direction to point their life. Does that make sense?

RB: Sure. Absolutely.

JL: So, you know I worked for Terrence O’Hanlon on Reliabilityweb.com for a couple of years. We used to do the Uptime Awards. And when I talked to the people who won the awards, they said that the value of the award was not from getting an award, it was from the aspirational direction. It pulled the whole team in the same direction to achieve great predictive maintenance, and to get great planning and scheduling. And as a motivator, that was really powerful.

My view of world class maintenance is first of all, somebody says they’re going to take you there and you are definitely going to go for a ride. And it’s going to cost! It’s saying, let’s do the best we can do. Let’s really get into this root cause analysis. And it involves everybody. The janitor should be working on root cause analysis for janitorial issues and operators and the maintenance folks and metrology and instrumentation…That’s where I think the power of world class is.

RB: So, it is aspirational and sets up standards in your own environment, so that you’re in a state of continuous improvement.

JL: One other part of that is, back in the day when benchmarking and world class became a big thing—this was in the 1990s—we always had two things: We had best in class, which was the best maintenance operation, and then there was best in the world, where that was the best of that function. When people call a maintenance department, are they talking to the best customer service representative or are they talking to somebody that couldn’t care less about their problem? So, we look to be the best.

RB: Let’s talk about the education of maintenance professionals. Your experience runs the gamut in maintenance—you’ve gone from process control designer, to source equipment inspector, electrician field service technician, merchant marine worker to manufacturing manager. You certainly have diverse experience. How would you say the education of maintenance and reliability professionals is evolving?

JL: I see things that are so cool in the training arena. I was at a trade show and I got to play with a virtual reality welding trainer. That was so much fun. That you could train somebody to weld sitting literally at a desk. And your hand would start to move correctly. We’re right on the verge of some really interesting shifts in training the trades. It’s still pretty much the way it was, although some areas are starting to change.

There’s a huge deficit of people in the trades and wherever in the world I go, I say, “What’s your biggest complaint?” And they say, “Finding skilled workers.” That’s like the biggest challenge. With new technologies, such as augmented reality—we’re seeing examples at BMW, where you put the glasses and it will basically tell you what to do. That doesn’t help for troubleshooting it, but it does help if you need to change an alternator. We’re on the verge of something really interesting. We just have to get through the next decade and not have our infrastructure collapse around us.

RB: Okay, it sounds as though progress in maintenance is a marathon, not a sprint. I mean, technology advances very fast, but for maintenance, I’ve always had the impression that it takes a lot of time and education to bring maintenance professionals along when there’s change.

JL: The other thing is that we lag behind consumer markets by a couple of years. The consumer markets don’t exist in maintenance yet. But how long before those people leave the likes of Microsoft or Apple, and join a company where they can put out the same technology for maintenance diagnosis? Certainly, it’s happening in medicine.

RB: So therein lies the opportunity, you would say?

JL: Yeah.

RB: Your latest installment for your illustrated series of Stories of PM (preventive maintenance) has just been published.

JL: It’s available on Amazon.

RB: Does this installment complete the series or will we be seeing some more?

JL: I’ve been talking to maintenance managers around the world and getting into conversations about what fundamentals are. I don’t know what the title is going to be, but is going to be the next one is about the quality of maintenance work. We’re seeing a lot of new people coming into the field and there’s a lot of concern among the higher echelons about maintaining the quality of the maintenance work. So, I’m working on that right now.

One of the things about quality is that a lot of the quality problems are not the traditional problems of the guy or gal just not being motivated. That’s not what’s going on here. What’s going on is that there’s frequently something missing, whether it’s specific information or specific tools or specific parts. So, we have to deal with that before we can demand quality.