Scenario: Joe, a maintenance worker with no hydraulic training, was fatally injured in an accident at a steel plant. Joe was standing on a stepladder, tightening a leaking hydraulic connector in a steel fluid line that was affixed to a wall approximately 12 ft above the floor. He purposely left the power unit running because he wanted the hydraulic system to be at maximum pressure — that way, he could see if and when the leak stopped as he tightened the connector.

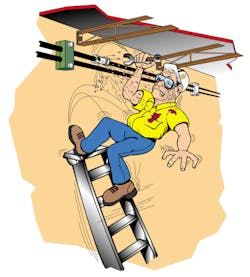

However, the connector unexpectedly failed. High-pressure hydraulic oil burst from the broken connector, striking him in the face and chest, Figure 1. Joe lost his grip on the ladder, and fell to the concrete floor below. He died as a result of the injuries he sustained from the fall.

Events that led to the accident

Joe noticed oil leaking from an overhead hydraulic oil transmission line between a power unit and a production machine. He used a stepladder so he could see what the problem was. After a brief inspection, Joe determined that the leak was coming from a threaded connector.

He returned to his toolbox to collect the appropriate wrenches needed to tighten the connector. However, he did not turn the machine off — or lock it out!

When the connector failed, high-pressure oil discharged from the damaged transmission line at high velocity. An eyewitness said that the force of the oil discharging to atmosphere literally blew the victim off the ladder.

What happened?

An investigation into the cause of the accident determined that the victim caused the tapered-pipe connector to fail because he over-tightened it. If he had shut the hydraulic power unit off, locked it out, and de-energized the hydraulic system, even though he still might have damaged the connector while tightening it, the force of high-pressure hydraulic oil discharging to atmosphere at high velocity would not have knocked him off the ladder.

Interestingly, it was also determined that his actions were practiced quite routinely in the plant.

Safety over logic

This is a hydraulic accident that will lure even the most adept and alert person. The potential downfall is nothing more than good old logic.

Here’s why: a hydraulic connector is leaking. If the pressure is left in the system, you will see if and when you have tightened it enough to stop the leak. However, if you turn the power off, and de-energize the system (relieve the pressure), which is the safe way to do it, how will you know if and when the leak stops?

In fact, the task becomes tedious because you have to continually lock out and de-energize, and then re-start and re-energize to accomplish, what appears to be the simple task of tightening a leaking connector.

Let safety prevail — assume that the reason why a connector is leaking in the first place is because it is damaged. Regardless of how much you tighten it, it is not going to stop the leak. In the case of a tapered-pipe connector, caution is critical. The tapered design encourages failure when it is over-tightened. It is always best to err on the side of safety — lock it out, de-energize, verify, and proceed with caution. Accidents of this nature are quite common. However, evidence shows that the vast majority goes unreported.

How this accident could have been prevented

Training — All people who work on and around hydraulic systems must be properly trained. Hydraulic training must include safety procedures.

Accident or mishap? — Hydraulics is already at a disadvantage: it is not a recognized occupational hazard. Many certified safety professionals cannot identify hydraulic hazards. Consequently, the vast majority of hydraulic accidents are written off as mishaps. All hydraulics accidents should and must be investigated. If not, sooner or later they will be out of necessity — when someone is injured or killed.

Job safety breakdowns — Most people who work on and around hydraulics are not properly trained. Consequently, written communication is critical to protect them from unforeseen hazards. Management should write a job safety breakdown for this task. Make everyone aware of the potential hazard.

Safety training — Discuss hydraulic safety in your safety meetings. Even though hydraulics is not currently a defined occupational hazard, it is in many respects more hazardous than electricity. Make hydraulic safety a part of your corporate safety culture.

Torque specifications — There are recommended torque specifications for all hydraulic connectors. Make these specifications available to all maintenance personnel.

The proper procedure

Here are general recommendations as to the proper procedure that should have been followed in this case:

1. Lock out and tag the prime mover.

2. De-energize the hydraulic system and verify that it is de-energized.

3. Refer to the connector manufacturer’s specifications for correct torque values, and/or tightening sequence. For example, there is a recommended tightening sequence for JIC 37° connectors. If it is a tapered pipe connector, you may have to apply a sealant to the threads.

4. Tighten the connector(s).

5. Remove locks and start the machine.

6. Visually check for leakage. Do not use your hands to feel for a leak.

7. If, after tightening a connector in accordance with the manufacturer’s specifications, the leak persists, it is probably damaged and must be replaced. Do not attempt to tighten it further. Over-tightening can weaken a connector and cause it to fail.

Rory McLaren is president, Fluid Power Training Institute, Salt Lake City. For more information, call (801) 908-5456, email [email protected], or visit www.fpti.org.

Caution: Rory McLaren and the Fluid Power Training Institute do everything possible to ensure that the information and drawings contained in these reports are accurate and that the suggested procedures are deemed safe and reliable. However, these are general recommendations only and might not be applicable to all situations. You must have your engineering and service departments read these recommendations and make the necessary changes for your specific conditions.The Fluid Power Training Institute is not responsible for actions taken by untrained or unauthorized persons. All hydraulic system service, repair, and troubleshooting should be conducted only by trained, authorized personnel.About the Author

Leaders relevant to this article: