Troubleshooting Challenge: Appliance manufacturer has sluggish polishing machine

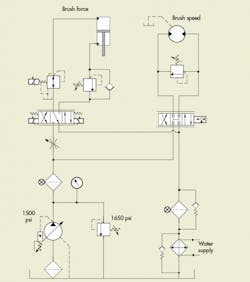

An appliance manufacturer has a machine that polishes the stainless steel exterior on the finished doors of appliances to a fine brushed look on one of its popular designs. The polishing head’s speed is powered by a servovalve hydraulic system that allows them to maintain the selected speed of the brushes.

This process had been in place for several years, and other than occasional maintenance fixes, worked well. They did a good job of maintaining the ISO cleanliness code and temperature of the hydraulic oil. Oil samples always came back reflecting good maintenance practices they had in place.

A problem developed where the maximum brush speed could not be achieved, but the circuit for advancing and applying pressure worked just fine.

The coils of the servovalve were wired in parallel, and when the resistance of each was measured, they both appeared to be fine. Technicians checked the signal coming out of the amplifier card to the servovalve, and it also seemed fine. They then replaced the servovalve with a new one after verifying the continuity of the cable going to the valve.

The system worked fine part of the time, but not consistently. Any idea what could be wrong?

Soution to Appliance Manufacturer has Sluggish Polishing Machine

The polishing machine's servovalve has two coils that controlled the tilt of the torque motor. When wired in parallel and properly wired in relation to their polarity, the coils produce enough force to fully stroke the valve. However, if one coil is open, the valve only has half the force stroking the torque motor. Therefore, the valve cannot open completely. This reduces the maximum flow capacity, which slows down the response time of the valve.

The fact that the polisher would work fine part of the time indicated that hydraulics was not the problem. I found that if the cable feeding the valve was moved to a certain position and held there, the system operated properly. Closer inspection of the cable, where it entered the connector, revealed a solder joint of one wire with a “cold joint.” This wire separated from the terminal when the cable was bent in one direction, causing loss of power to one of the servovalve's coils. Re-soldering the wire to the terminal solved the problem.

About the Author

Bob Sheaf

President

Robert J. Sheaf Jr., is the founder and president of CFC Insustrial Training, formerly Certified Fluid Consultants, part of CFC-Solar Inc. CFC-Solar provides technical training, consulting, and field services to any industry using fluid power technology.

Leaders relevant to this article: