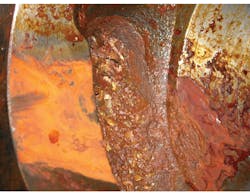

Surface damage caused by cavitation.

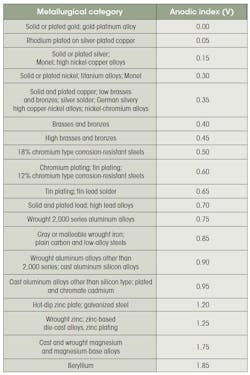

Pay close attention to the type of fluid chosen for the system. Some fluids are more conductive (such as water/oil emulsion) than others, creating a high potential for corrosion. Others (such as water glycol) display high electrical resistance, which inhibits corrosion.

Any system using a conductive fluid should be carefully monitored for any stray DC voltage leaks. Just one poor ground connection on equipment using a conductive water-based fluid can cause electrolysis to quickly corrode components, beginning with the least noble metal in the system. Aluminum, cast iron, and steel will typically be the first metals to be attacked. Also, note that every 10° F of temperature rise will double the rate of corrosion.

Preventive Measures

Some precautions can be taken to minimize corrosion due to galvanism and electrolysis:

- Apply coatings to metal surfaces to create a barrier between the metal and the electrolyte solution.

- Incorporate sacrificial materials (such as zinc) into the system to be preferentially corroded instead of allowing important metals to corrode. Unfortunately, this technique introduces a contaminant (zinc oxide) into the fluid.

- Select a fluid with low electrical conductivity.

- Specify components made of materials that are high on the scale of nobility.

Many variables exist in every system, and a perfect balance cannot realistically be achieved. Careful monitoring and stringent maintenance practices must be observed to ensure proper function and longevity of the system. The original design should take into account the type of fluid intended for use in the system.

Any hydraulic system that uses a conductive-type of water-based fluid will, no doubt, be subject to enhanced corrosion potential. To avoid this problem:

- Select components carefully to avoid using those made of dissimilar metals.

- Carefully monitor any DC electrical functions incorporated in the system to locate and resolve any poor grounding or other source of leaking voltage.

- The fluid is the single most important component in any hydraulic system, so regularly analyze it to monitor the overall health of the system.

- Consider using additives to decrease the electrical conductivity of the fluid.

Russ Rochambeau is engineering manager at Valin Corp., San Jose, Calif.