Use an Infrared Heat Dectector to Assess Health of Hydraulic Systems

Probably the best part of my job is meeting and working with many truly outstanding people. Jim Mollo was certainly one of these. For decades, Jim worked as a hydraulic system designer and troubleshooter all over the world. He was a great storyteller, and he often shared some of his exploits when we spoke on the phone.

But Jim was a brilliant designer and held many patents, including those for a load-sensing gear pump, which he had licensed to JS Barnes pumps and Champion Road Graders, if I remember correctly. Parker Hannifin also produced load sensing gear pumps that may have been been based on his design. Jim was also truly innovative and always looked for better and simpler ways to get things done. Which brings me to this blog.

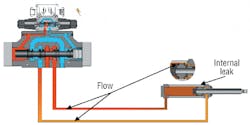

Jim wrote about what I feel is one of his most innovative ideas way back in 2001. I think the article was far ahead of its time, and all the concepts and principles he proposed are still relevant — and innovative — today. Simply stated, the article explains how you can use an infrared heat gun to assess the health of a hydraulic system. Some of the discussion gets pretty detailed by explaining how the concept works with different types of components, such as servovalves and even cylinders.

But enough of my rambling, click here to read the article.

About the Author

Alan Hitchcox Blog

Editor in Chief

Alan joined Hydraulics & Pneumatics in 1987 with experience as a technical magazine editor and in industrial sales. He graduated with a BS in engineering technology from Franklin University and has also worked as a mechanic and service coordinator. He has taken technical courses in fluid power and electronic and digital control at the Milwaukee School of Engineering and the University of Wisconsin and has served on numerous industry committees.