Some campers carry all their gear on their backs as they walk into the wilderness. Others prefer to tow all the comforts of home in a trailer behind their trucks. The latter group even includes people who need more living space when they reach their destination, so they buy trailers or RVs that have the slideout room option. This enhancement is a room that nests into the trailer or RV during transportation, then slides out to provide more usable space.

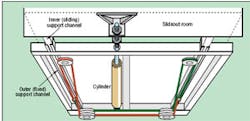

The rooms are not particularly heavy, but their size makes them awkward to keep aligned. Parker Hannifin's Oildyne Oildyne Div., New Hope, Minn., and Dewald Mfg. Inc., Mishawaka, Ind., are marketing partners for the Hydra-Sync, a hydraulically powered, cable-synchronized slide assembly that can extend slideout rooms or return them at the touch of a button. Hydra-Sync systems are generally more quiet, smoother running, faster, and more powerful for the same current draw than competitive electromechanical systems.

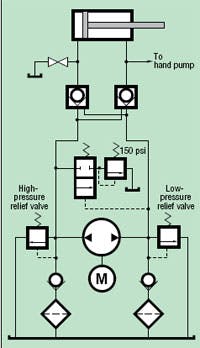

Mounted under the vehicle, a double-acting hydraulic cylinder — supplied from a compact Oildyne power unit with reversible locking circuitry — generates over 4000 lb of force while an independent, patented cable-and-pulley arrangement keeps the room aligned during movement. Cylinder strokes from 24 to 44 in. are typical, and installation is uncomplicated. A positive mechanical stop system, located on the cylinder rod, assures that force is only applied to the room during movement. This positive stop is accurate to within thousandths of an inch and should not need adjustment over its lifetime — even if the frame rusts or is not properly lubricated. Once the room reaches full extended or retracted position, loadholding checks in the hydraulic circuit maintain it there. This keeps the room's weather seals from relaxing to allow any potential leakage, while the room structure is not stressed or forced to move past its travel limit.

In contrast, 12-VDC electric motors driving mechanical gear trains generally produce just enough power to move the room. To operate properly, they are dependent upon exact alignment of all frame support members. They need additional rollers and proper lubrication of support members to minimize friction. An electric system must shut off immediately when the room reaches either extreme position, or it will blow a circuit breaker, burn out the electric motor, or strip a rack or pinion gear. For this reason, electric systems require a current sensing shutoff switch or several limit switches. Both types of switches may be difficult to adjust.

The Hydra-Sync system is not damaged by continued running after the room has reached full travel in either direction. The room stops exactly where it should, and the pump simply recirculates oil internally. If electric power is lost, an integral manual pump can retract the room.

An additional advantage of the hydraulically powered system becomes evident when an RV has a second slideout room. The same power unit can move both rooms, so all that is required for the second room is another cylinder and two more hoses. In contrast, the entire electric system must be duplicated for each room, so hydraulic systems realize a large cost savings for multiple slideout room RVs.

Contact Parker Hannifin's Oildyne Div., New Hope, Minn., at 763/533-1600 or click here to visit the website.