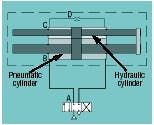

Hy-P actuator uses pneumatics for power and self-contained hydraulics for control.

Latest application

In April of 2005 RB Hybrodynamics completed development of a 6-in. bore linear actuator with a failsafe hydraulic lock that will hold a static load — the Series LLK. These actuators are the largest produced so far, but they actuators are not limited to this size.

The actuators were developed for the Fluid Sciences Div. of Perkin-Elmer Co., which specializes in aerospace and energy technologies, fluid testing, and providing components and subassembly integration processing services to semiconductor manufacturers. Perkin-Elmer technicians retrofitted their existing test equipment that provides and maintains a specified amount of test load in a predetermined position.

Even thought the application required generating several tons of force, conventional hydraulics was deemed unacceptable for the application. However, electromechanical servoactuators would not be able to transmit enough power within size, weight, and price constraints.

LLK actuators have been installed and currently are undergoing testing at Perkin-Elmer facilities. This testing will continue throughout the period of active service without maintenance. RB Hybrodynamics is monitoring the performance of these units by collecting feedback information from the field and using it for optimization and improvements of existing models and to drive future development.

From simple to sophisticated

The basic Hy-P hybrid actuator, Series LO, is intended primarily for simple applications such as presses and pneumatically powered feeding devices. It is said to be capable of providing adjustable speed and accurate positioning in applications where locking in position is not needed.

LO units come with any of three factory-set damping rates for specific speed ranges at 100 psi supply pressure and zero load: 0.1 4 in./sec, 3 7 in./sec, and 6 12 in./sec. Velocity can also or instead be adjusted using conventional pneumatic controls, such as needle valves to meter incoming flow, exhaust flow or both, or via pressure regulators. Standard bore sizes for all types range from 11/8 to 6 in.

This information was provided by Mark Y. Shteynberg, engineering consultant. For more information, visit www.rbhybro.com, or e-mail [email protected]