Troubleshooting Challenge: Hydraulic system causes structural failure

I was asked to examine and review the circuit design on a walking-beam conveyor system in a pipe mill that had one of two lifting cylinders suddenly drop. This caused one side of the structural frame to fracture, dropping a 60,000-lb coil of ½-in. steel into a pit.

Typical walking-beam systems have long horizontal beams that cradle a heavy load — in this case, several coils of steel. A traverse cylinder moves the beam horizontally into the entry side of a pipe forming mill. All the coils of steel are then raised off the beam vertically and held in this raised position while the traverse cylinder retracts, pulling the horizontal beam in the opposite direction. The coils are then lowered back onto the beam that’s been retracted to its home position. Then the traverse cylinder again extends, moving the newly positioned coils closer to the entry position of the mill. This process keeps repeating (walking) the coils into the entry position.

This file type includes high resolution graphics and schematics when applicable.

When all of the vertical lifting cylinders were told to retract to lower the coils at a slow gentle speed, one cylinder dropped so quickly that a 60,000-lb coil free fell about 18 in. and destroyed the beam’s cradle and superstructure.

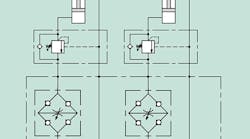

Looking at the circuit, what do you think caused this problem?