Master-slave setup synchronizes cylinders

Equipment manufacturers are continually challenged to find ways of increasing the productivity of their machines. When their machines require human intervention, they often design their machines around an “average” height of an individual. The problem is, most individuals are taller or shorter than this average height. The greater the differential height, the greater the likelihood that the person’s productivity will suffer.

To reduce or eliminate the problem of varying heights of individuals, OEMs can build their machines with adjustable height capabilities. This is often accomplished with mechanical and electromechanical assemblies, but when the equipment is exceptionally heavy, or designers want a mechanism that’s compact enough to be hidden from view, hydraulics, of course, provides a practical solution.

Ergoswiss AG, Windau, Switzerland, offers a variety of lifting mechanisms that use an unconventional hydraulic system. The Ergoswiss hydraulic system features a pump that supplies multiple cylinders with equal amounts of hydraulic fluid, thereby ensuring that all cylinders move in unison.

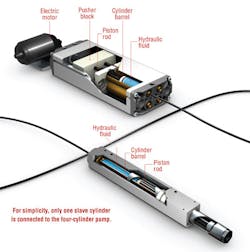

The system starts with a pump containing two to ten master cylinders, and each master cylinder is plumbed directly to a slave cylinder. The pump is powered by an electric motor that drives a lead screw. The screw transmits power to a pusher plate, which converts the rotational speed and torque of the screw into linear force and motion to drive the assembly of master cylinders.

To ensure synchronized motion of all cylinders, all master and slave cylinders are identical in size, as are the hose assemblies connecting them. The cylinders are all single acting and require a force of at least 5 kg per cylinder for retraction.

Advantages are smooth, stepless motion and extremely quiet operation. And as is typical of hydraulics, actuators are extremely compact, allowing transmission of high forces from a small envelope. The pump is powered by an electric motor or by a hand crank, which also serves as an auxiliary power source in case of electrical failure.

System components

The compact pumps are powerful enough to move loads as heavy as 1000 kg at lifting speeds to 30 mm/ sec. Each system is powered by 230 V ac (110 V ac optional) and drives a dc motor at a maximum speed of 120, 140, or 210 rpm.

The Ergoswiss model CE cylinder is typical of those found in the system. It has a bore of 14 mm and a stroke of 40 cm, with strokes to 70 cm available, depending on the model. The maximum load per cylinder is 1500 N, with 2500 N available. Two-stage telescoping cylinders are also available.

The hydraulic hose connecting each slave and master cylinder pair has a 4-mm OD, a minimum bend radius of 25 mm, and maximum operating pressure of 100 bar.

Height is controlled using a handheld, foot operated, or panel-mounted keypad. Digital remote control is optional, as is programmable memory, which raises or lowers the work surface to a predetermined position simply by entering the appropriate value.

All components feature a clean, smooth design, which allows them to be integrated into a variety of applications — operating tables, massage couches, beds, workstations, laboratory benches, cashier stations, food processing equipment, transfer stations, conveyors, etc.

For more information, visit www.ergoswiss.com.