Innovation will prove key to survival for those in the mining industry—a necessity driven by growing competition from original equipment manufacturers (OEMs) in the Far East as they race to bring their products in line with the standards set by Western counterparts. Likewise, OEMs in the West must strive to keep a distance between their own technical innovations and those of the new players.

The real solution lies in raising the performance and output capabilities of mining and construction components. This entails improving efficiency and productivity without compromising safety, and minimizing operational breakdowns for altogether more cost-efficient operations. However, problems are arising due to inadequate performances from components that are manufactured from conventional engineering steels (such as plain carbon steel), often resulting in costly and disruptive equipment failures.

Piston Rods in Hydraulic Cylinders

Hydraulic piston rods are a case in point where conventional steels are performing inadequately. These instances have resulted in oil leaks or pressure loss, or else have necessitated regular and disruptive cylinder changes. Analysis has determined that these failures are caused by cyclic stresses, which are typical in demanding mining and construction applications, and to which piston rods are commonly exposed over long periods. The challenge for OEMs: How can the costs attached to the piston rods be reduced in spite of these problems?

The main driver of cost and capital in piston rods in hydraulic cylinders is the diameter of the bar. Costs of the material, handling, and cutting increase in concert with the weight of the bar. Meanwhile, the cost of surface operations—machining, grinding, chrome plating, and so on—increase with the surface area. The cost of a rod increases exponentially with the diameter as a result.

As a general rule, the cost of a piston rod decreases by 15% by reducing its diameter by 5 mm. Other effects are lighter weight and reduced space requirements, which could also translate into lower energy consumption and greater versatility in design.

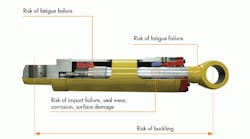

But to achieve these benefits, the rod material must be strong enough to maintain equal strength at the smaller diameter. Therefore, a key parameter in hydraulic piston-rod design is dimensioning against fatigue, buckling, and impact failure (Fig. 1).

Fatigue Research

For decades, Ovako Steel has conducted comprehensive research in fatigue behavior and failure, and built an extensive database of detailed performance data. The risk of buckling in piston rods depends on the yield strength, the elastic modulus of the material, and the geometry of the rod, as defined by the slenderness ratio. European Convention for structural steelwork (ECCS) and American Institute of Steel Construction (AISC) recommendations define the buckling stress as a function of slenderness ratio (λ):

λ = 4L / d

Generally speaking, the buckling stress at small slenderness ratios corresponds to the yield stress of the material and decreases with increasing slenderness ratio to the extreme case, where it becomes independent of yield strength.

In practice, 70 to 80% of all hydraulic cylinders are designed with low or moderate slenderness ratios (below 100). That means the yield stress of the material has an important influence in defining the required diameter of the rod for cylinders operating in conditions where there is risk of buckling.

However, a piston rod in many instances operates in a dynamic environment with push-pull forces, and in which it will be susceptible to fatigue. Each rod has a unique fatigue limit, and dimensioning is made on the basis of experience, or else through fatigue testing of finished piston rods or cylinders.

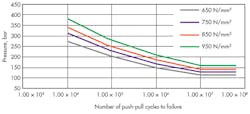

All other things being equal, fatigue strength increases with the tensile strength of the rod material. Because the main cost driver is the diameter of the rod, it follows that the strength of the rod material is the main lever to reduce cost by dimensioning the rod against fatigue (Fig. 2). Compared to the most commonly used material for hydraulic cylinder rods, C45E, Ovako has measured that the cost-reduction potential achieved through the use of stronger materials is on the order of 20 to 30%.

Nevertheless, not all high-strength steels are suitable for piston rods due to problems deriving from the inherent impact of slag inclusions, which intersect the surface and create segregation at the center of the rod. Indeed, it is not unusual that chemical compositions aimed at promoting strength or machinability can end up being the cause of problems in welding, and in friction welding in particular. Moreover, certain slag inclusions at the surface of the material will dissolve during the chrome plating process, giving rise to porosity, which can translate to weakness in the chrome layer.

The true cost effect of different steel materials for a piston rod is complicated to assess. However, a simple approach could be to first select several grades with sufficient impact toughness and suitable machinability/welding characteristics, and then choose the one which offers the lowest price per unit of yield strength.

Cromax is a line of chrome-plated and nickel-chrome-plated bars and tubes primarily used as piston rods in hydraulic cylinders. These steels have been developed specifically for the manufacture of piston rods in hydraulic cylinders. They can be thought of as “piston rod steels,” in much the same way that steels developed specifically for ball and roller bearing applications are referred to as bearing steels.

Plating with Nickel-Chrome

Steering systems, suspension systems in vehicle cabins, and the tilting mechanisms in forklifts typically have one critical component in common: hydraulic cylinders. These cylinders and the hydraulic systems they support have long been taken for granted. But without their ability to withstand corrosion, dynamic loads, and constant wear-and-tear over many years, these components and the piston rods that drive them would be subject to frequent failure.

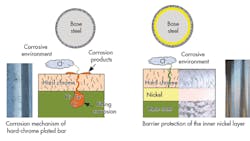

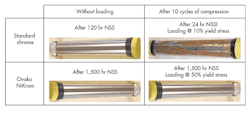

Plating with chromium is by far the most common surface treatment for piston rods. Nevertheless, chromium has poor ductility and all chrome-plated layers have micro cracks, which can let the external environment penetrate the layer and cause corrosion. This can be rather swift in corrosive environments or safety-critical mining and construction applications, where the rod is exposed to mechanical damage. The chromium can be combined with an underlying layer of nickel, which dramatically improves corrosion resistance (Fig. 3).

Due to its high ductility, the nickel-chrome layer is able to maintain its corrosion properties in the field, including in aggressive mining and construction environments. Random testing is also vital to maintaining the performance of the hydraulic cylinders—e.g., the compression and corrosion testing (Fig. 4).

To protect rods from damage in the event of external impact, induction hardening of hydraulic cylinder piston rods has proven beneficial in demanding mining and quarrying applications. Induction hardening can also improve the mechanical properties of the rod—especially resistance to buckling failure in push mode. Relative to a non-hardened rod with the same steel base, the diameter of an induction-hardened rod can also be downsized for reduced weight and lower costs.

A further significant lever to reduce the cost of the piston rod is to minimize the thickness of the chrome or nickel-chrome layers. In safety-critical applications where the component is exposed to risk of mechanical damage, cylinder manufacturers should select the thinnest combination of chrome and nickel to provide sufficient corrosion protection after multiple compressions.

Quality Through Cleanliness

Quality is among the main demands that customers place on Ovako steels. The quality of steel pertains specifically to its cleanliness, or the presence within the metallurgy of defects such as non-metallic inclusions—foreign substances produced by chemical reactions during melting and pouring processes that disrupt the steel’s structural homogeneity.

Non-metallic inclusions are shown to create cracks and fatigue failures in steels. These cause many conventional steels to fail when subjected to the non-steady, continuously varying loads and cyclic stresses that occur in demanding mining applications. Based on analysis of thousands of fatigue failures with scanning electron microscope (SEM) technology, Ovako engineers are able to demonstrate how the quality of steels significantly impacts the fatigue life of components.

Poor performance typically arises with conventional steels because they are anisotropic, or directionally dependent, by nature. Inclusions become deformed or elongate within the steel during the rolling stage, so its fatigue strength will be higher when loaded parallel to the rolling direction than if it is loaded transverse to the rolling direction.

Per Israelsson is head of marketing & technology, Ovako Cromax Group, Ovako AB, Stockholm, Sweden.