Troubleshooting Challenge: Hot Dog Machine Has Weight Problem

This file type includes high resolution graphics and schematics when applicable.

A packing house has a hot dog machine. It starts off with raw meat from large tubs dumped into grinders that feed the hot dog production line. After spices and fillers are added, the mixture is inserted into a casing material and cut to length. Then the raw hot dogs pass through an oven, and are subsequently wrapped and labeled. Finally, the packages are quick-frozen and packed into cartons for shipment.

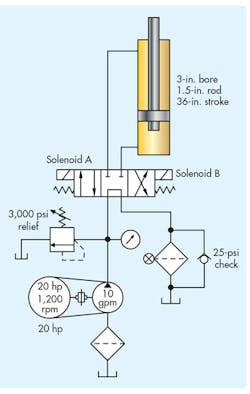

The large tubs of raw meat are lifted and dumped using a simple hydraulic system (see schematic) consisting of a cylinder that lifts the tub up to dump the meat into the grinders. Over time, operators noticed that if meat was fully loaded to the top of the tub, the cylinder could not lift it.

A maintenance worker replaced a broken pressure gauge and found that the hydraulic-system pressure maxed out at only 1,700 psi, even though the relief valve was set at 3,000 psi. The 1,700 psi did not generate enough force from the cylinder to dump a full tub. However, when operators reduced the load on cylinder by only partially filling the tub, the cylinder operated at the correct speed.

Of course, the first thing the maintenance people did was replace the pump, only to have the same result. They verified that the relief valve was not relieving oil to the tank at 1,700 psi and that the cylinder wasn’t leaking oil from the rod-end hose.

What do you think was causing the problem?

Find the Solution

Think you know the answer to this month’s problem? Submit your solution by e-mailing Robert J. Sheaf Jr. All correct solutions submitted by April 1, 2017, will be entered into a random drawing for a $50 gift card. The winner will be notified, and his or her name will be printed in a future issue. Only one gift card will be awarded to any participant within a calendar year.

Congratulations to Joel Mekkes, of HydraForce Inc., Lincolnshire, Ill., who correctly answered last month’s problem. A $50 gift card will be sent to him.

Solution to Last Month’s Challenge:

800-Ton Press Suffers from Severe Stuttering

The stuttering on the 800-ton press was caused by the position of the proportional valve’s solenoid—the coil was only halfway on the core tube. When the plant’s maintenance crew installed the solenoid earlier in the week, they temporarily removed the solenoid for wiring ease. However, they later forgot to install the retainer nut (which keeps the coil in the correct position) onto the core tube.

With the coil only partially over the armature, forces generated by high oil flow would overpower the magnetic force of the coil, causing the spool positioning error. Once the flow decreased, the flow forces became lower. This allowed the coil to again open the spool wider, and the process kept repeating.

This file type includes high resolution graphics and schematics when applicable.

About the Author

Robert Sheaf

President

Robert J. Sheaf Jr., is the founder and president of CFC Industrial Training, formerly Certified Fluid Consultants, part of CFC-Solar Inc. CFC-Solar provides technical training, consulting, and field services to any industry using fluid power technology.

Leaders relevant to this article: