In conventional cylinders, of course, a piston pushes or pulls a rod that moves a load through some sort of mechanical linkage. This works great for most applications, but if you’re cramped for space, or need the same area on both sides of the piston, a rodless cylinder may be the best solution. Most rodless cylinders move a load from the piston itself, rather than the rod, which provides several advantages.

What Rodless Cylinders Do Best

Rodless cylinders differ from conventional rod-style cylinders in several ways that offer distinct advantages for certain types of applications. The two main benefits may seem contradictory at first—rodless cylinders conserve space, but they also allow for a longer stroke within the same space as a conventional cylinder. They save space because the stroke is contained within the envelope of the cylinder body. With a rod-style design the stroke only begins at the point at which the rod leaves the tube, so the space required includes the length of the cylinder body plus the length of the stroke. With a rodless design, the full stroke fits in the footprint of the cylinder. In other words, rodless cylinders can deliver the same stroke in roughly half the space of a rod-type cylinder.

So how can rodless cylinders deliver even longer strokes? The constraint for rod-type cylinders is rod length. The longest stroke for which a rod can be constructed practically is approximately 12 ft. It would require specialized material to construct a rod longer than that. In contrast, it is possible to construct a rodless cylinder with a stroke up to 27 ft. using lightweight, extruded aluminum alloy.

Rods have another issue. Depending on length and the force applied, they can buckle. With no rod, there is no buckling and less chance of distortion.

Another basic characteristic of rodless cylinders is that they move in both directions with the same force. This differs from rod-style cylinders that produce maximum force for extension, and a lower force for retraction. Applications that move loads in both directions may require two different load calculations, and you may need to oversize the cylinder to accommodate its lower potential retraction force. Using a rodless cylinder eliminates these limitations. It also allows for more accurate, repeatable mid-stroke positioning because the force is the same in both directions.

Background on Rodless Cylinders

The earliest rodless cylinder design was a cable cylinder. Still used today, this type of cylinder uses a cable that wraps around a pulley and attaches to either end of the piston to move a carriage or yoke for conveying the load. As the piston moves one direction—pulling the cable with it—the yoke moves the opposite direction.

The biggest challenge with these cylinders is cable wear. As with any equipment powered by compressed air, leaks are the enemy. Lost air means lost pressure, so loads are moved less efficiently and energy is wasted. As cables wear, they stretch and get thinner, opening up a path for air leaks.

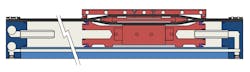

More commonly used today are cylinders where the carriage is coupled with the piston so they move in tandem. One way to do this is to connect the piston and the carriage by way of a magnetic field. With no opening and no cable, this design is clean and leak-free. However, magnetic cylinders are vulnerable to decoupling and carriage rotation, and their load capacity is lower than with other designs, making their use somewhat limited. They work best for applications with lower speeds, relatively low impact, and lighter loads.

Slotted Design—Three Guide Systems

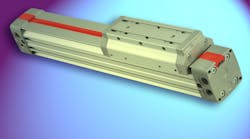

The most versatile and widely used type of rodless cylinder today is the slotted tube design, first introduced in 1977. These use a carriage that is directly connected to the piston through a slot in the tube. This simple design is less expensive to produce than most other designs. More importantly, it allows for multiple guiding options, it can be built for extremely long strokes, and can be configured to carry heavy or off-balance loads.

Three different types of slotted rodless cylinders are used: internally guided, externally guided, and roller guided.

Internally guided cylinders have a carriage that sits on top of the tube and is connected to the piston. These are basic workhorses, good for applications where loads are not too heavy and do not tax the mechanical carrying capability of the cylinder.

Some operations incorporate their own system for guiding loads, such as guide rods mounted on the cylinder carriage. An internally guided cylinder is usually adequate in these instances. An internally guided system works most productively when the operation is simple and the load is consistently centered. Of the three types, these cylinders have the most limited guiding capability.

An externally guided cylinder should be used for applications with more challenging mechanics. As with an internally guided cylinder, the carriage of the externally guided design is connected to the piston, but the carriage also wraps part way around the outside of the tube. This provides additional bearing surface area for the carriage, which increases the moment load capability of the cylinder (see “Seize the Moment”).

A rodless cylinder that uses roller bearings to guide the carriage along the side of the tube offers the highest moment load capability of all. It is also more versatile, as it can accommodate loads that are farther from center, either along the cylinder path or to one side or the other.

Keep It Clean

Contamination can cut short the life of any pneumatic equipment, including cylinders. Slotted rodless cylinders are vulnerable like any others to environmental dust and debris, such as sawdust or paper fibers. Slotted cylinders are designed with seals along the slot that open as the carriage passes and close behind it. Some have optional aggressive wipers to keep debris off the tube.

Careful mounting can reduce the risk of particle contamination. Simply mounting the cylinder with the carriage underneath instead of on top puts gravity to work making particles fall away from instead of into the carriage and cover strip, reducing the risk of contamination.

Powering the cylinder with clean, dry, lubricated air will also prolong service life. A filter/regulator/lubricator (FRL) located upstream from the cylinder will keep moisture and contaminants out and let metered lubrication in. A rodless cylinder can travel up to 10 million ft. over its life if the compressed air that powers it is lubricated. Without air lubrication, even pre-lubed cylinders will last only about half as long.

Wide Variety of Applications

Over the years, engineers and designers have come up with all sorts of imaginative ways to take advantage of the special characteristics of rodless cylinders, especially their high stroke-to-length ratio, stability, footprint, light weight, controllability, side-loading capability, and consistent force in both directions. From old-school manufacturing to the latest in optical sorting, some common examples include:

- Commercial sewing—move a machine down the length of the stitching operation

- Industrial doors—quick open and close in automatic car wash or forklift entrance to cool storage

- Printing—flying knife to cut paper at the end of a roll

- Food and beverage—lane diverters in bottling or food packaging

- Warehousing lift—move loads up to two stories by mounting a shelf to the carriage of a cylinder installed vertically

- Silk screening—apply even pressure in a straight line

- Automotive—apply side molding to auto bodies

- Optical sorting—remove defective parts (or bagels or cookies) from conveyor as identified by optical sensors

- Conveying—transfer loads

- Manufacturing—mount one cylinder at a right angle to another to create a walking beam that moves loads horizontally and then places them vertically

- Spray painting—mount and move spray equipment for consistent, repeatable coverage

- Packaging—move and boxes and load them, into cartons

- Tire fabrication—cut rubber at an angle for joining seams

- Robotics—move tooling between stations in a manufacturing cell

Rodless cylinders are so versatile and reliable that they continue to find their way into new manufacturing technologies unimagined when they first came on the scene.

Seize the Moment

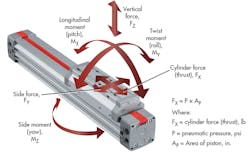

Clearly, a cylinder must have a long enough stroke to do the job and be strong enough to carry the weight of whatever load is being moved. But the calculation is more complicated than just these two factors. The term for all the variables that must be considered in sizing a cylinder is a word borrowed from physics: “moment” – the product of force times distance.

Simply put, force is pressure multiplied by area. So, the bigger and heavier an object, the greater the force. When discussing cylinders, moment means the force of the object being moved multiplied by its distance from the center of the piston.

You must understand and account for the moment specific to the operation before sizing a rodless cylinder and choosing the right guidance. The farther the load is from the carriage, the greater the moment. The heavier or bulkier the load is, the greater the moment. And the moment calculation varies depending on how the cylinder is mounted and where the load is: above, below, or off to one side.

All of these things are key to calculating the correct cylinder size for a given application. An experienced manufacturer can evaluate an application and help calculate the size cylinder required.

Sheila Campbell is application project engineer at Norgren Inc., Denver, an IMI Precision Engineering company. Click here for more information on rodless cylinders.