Weighing Pneumatic Actuators Against Electric

The role of pneumatics in packaging has been an interesting point of discussion for several years. Due to the low-cost mechanical actuation they provide, pneumatic actuators have been a staple in the packaging industry and were commonly used as the main energy source within a valve package. As alternative energy sources have been introduced over time, there are fewer pneumatic actuators operating in the world. One of these alternative sources is an electric actuator. Because electromechanical actuators are more energy-efficient than those using compressed air, electric actuators have become an attractive alternative to pneumatics.

Valid reasons certainly exist for choosing an electric actuator over a pneumatic one, but some facts about pneumatic actuators should be addressed before dismissing them as candidates for any particular application.

Conceptions and Misconceptions

Pneumatic actuators were a preferred method of actuation initially due to their low cost. However, as the industrialized world has evolved, cylinder speeds and the number of cylinders used in packaging operations have increased. More energy was required to run these robust operations, and end users began to express concern. Due to the rising cost of compressed air, pneumatic actuators began to be frowned upon and alternative options were sought out. The amount of compressed air that was beginning to be required in plants posed a problem in the budget. But was the compressed air being used efficiently? As this was further investigated, the question became, “How much compressed air is actually required for the pneumatic actuators?”

Facilities began conducting air surveys to gain a more accurate picture of how their compressed air was being used. What was eventually discovered was that the high cost of compressed air was not so much due to the pneumatic actuators, but to the piping design and leaks throughout the plant. These leaks are widespread throughout the industry, and although many associate pneumatic actuators with the rising costs of utilizing compressed air, piping leaks can shoulder much of the blame. As awareness of this phenomenon grows, and the leaks are identified and appropriately addressed, the cost of compressed air can decrease significantly. Although cost may still be top of mind for operators, ensuring that a plant’s piping is running efficiently is critical.

One of the biggest advantages pneumatic actuators have over electric is the flexibility pneumatics provides in its mounting capabilities. Electric actuators are generally confined to a very particular mounting style. Pneumatic actuators can adapt to several different applications. For an electric actuator (and with apologies to Henry Ford), you may choose between different pivot positions, as long as it’s a rear pivot. At this point, using an electric actuator becomes a retrofit, and mounting becomes more difficult.

Environmental issues become a factor in the decision-making as well. If there are areas where the environment is not suitable to come into contact with an electric actuator, a pneumatic actuator can offer a solution. With an electrical actuator, there is always going to be an electrical connection to the actuation. Often, it is the connection that becomes the weak point of the actuator.

Another misconception is that belt-driven actuators offer a more practical solution for long strokes than pneumatic cylinders do. However, pneumatic actuators are capable of a much longer stroke than electric actuators and offer additional mounting versatility when rodless cylinders are thrown into the mix.

Standing Up to Washing Down

Machine washdown is another area where pneumatic actuators offer an advantage. While electric actuators may not meet the demands of the process depending on the degree of protection required for the specific machine wash-down, there are several manufacturers offering pneumatic actuators that do.

Often, it is the pneumatic valving that requires an enclosure to meet specific washdown requirements. As previously stated, the electric actuator’s interface is generally its weakest point. However, in a washdown situation, depending on the severity, the electrical connection cannot handle it. This excludes an electric actuator from being used. If a pneumatic actuator is properly configured, it will have the ability to withstand a washdown.

However, the distance the valve package is located away from the actuator is critical. The farther away it is, the longer response time is for it to retract. In the past, operators would mount their pneumatic valving in a stainless-steel box in a wall 50 ft. away from where the cylinder was. Today, products that truly stand alone are part of the machine member, can withstand the washdown, and are only 5 ft. away. This increases production because it increases speeds. It allows the OEM to place the valve package as close to the point of work as possible.

Benefits of Electrics

What are some disadvantages associated with pneumatic actuators that electric actuators do not suffer from? First and foremost, electric actuators are more energy-efficient. If an application is served just as well with an electrical actuator as with pneumatics, many designers will opt for electric.

In addition, if machine motion requires an acceleration or deceleration ramp or a changing motion profile, a pneumatic actuator may not be up to the task. Although some suppliers offer high-end electropneumatic motion- and force-control systems, most machine designers are familiar with electromechanical actuators and specify them.

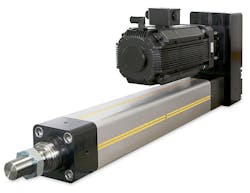

Advances in valves and cylinders allow pneumatics technology to continue to be a practical form of power transmission in packaging machines and other industries— especially those requiring high levels of speed, safety, and high reliability. (Image courtesy of Parker Hannifin Corp.)

If an operator needs to change the speed near the end of a stroke, a pneumatic actuator has typically been viewed as a limitation to pneumatics. End-of-stroke cushioning can provide some deceleration control. Acceleration, deceleration, and speed are easier to control and change with electrics. For example, if a fragile load is traveling down a conveyor and has to be stopped or diverted, a pneumatic actuator would likely create an impact that could damage the work piece. An electromechanical actuator, however, could be programmed to quickly accelerate and match its speed to the work piece to gently move it or decelerate it to a controlled stop.

Comparing this electromechanical actuator to its pneumatic counterpart makes it clear that pneumatics offers a lighter, more compact solution for producing linear motion. However, designers usually specify electromechanical actuators when an application requires controlled acceleration, deceleration, velocity, and position. (Image courtesy of Parker Hannifin Corp.)

Pneumatics on the Move

Even though many consider pneumatics a mature industry, advancements continue to be made. For example, new component designs exhibit higher efficiency than their predecessors from just a few years ago. Plus, closed-loop electropneumatic systems offer programmable motion and pressure control to combine the advantages of both electric drives and pneumatics.

A trend in pneumatic cylinders has been high-speed pneumatic cushioning to provide deceleration at the end of a stroke and a faster overall cycle time than an electric actuator can provide. Some ISO-type cylinders provide proven high-speed pneumatic cushioning, but the U.S. market has shown a preference for NFPA cylinders to maintain a uniform configuration throughout the machine. However, some NFPA non-lube cylinders now provide the type of high-speed pneumatic cushioning needed for the packaging industry.

There is a place in the packaging industry—among others—for both electric and pneumatic actuators. It all depends on the machine it is used in and the desired outcomes.

About the Author

Bill Nevills

Technical Specialist

Bill Nevills is a technical specialist concentrating in pneumatics and automation for Valin Corp., San Jose, Calif. For more information, call (888) 774-5630, or visit www.valin.com.