Small Fittings Take on Big Responsibility

Download this article in PDF format.

Because airplanes cannot back up, aircraft tractors are used to move them away from a gate and transfer throughout the airport. The new AST-2P/X, named the Phoenix, is the fourth generation of towbarless tractors designed and built by Goldhofer AG, Memmingen, Germany. It can move more than 80% of all commercial aircraft in use worldwide, including the new Airbus A350 and the B777X, now under development by Boeing.

In a record time of less than 60 seconds, the Phoenix aircraft tractor from Goldhofer engages an airplane and is ready to begin moving it. (Photo courtesy of Goldhofer GmbH)

Goldhofer combines a proven hydrostatic drive system with a differential lock to offer greater maneuverability and—thanks to the vehicle’s load distribution—optimized traction, steering, and braking of Goldhofer aircraft tractors. Operator guidance is aided by a central touchscreen that provides effortless and precise handling of aircraft up to 352 tons.

The Phoenix deploys swivel arms of its receiving mechanism to envelop, clamp, and lift the aircraft’s nose gear. With the nose gear secured, the tractor can move the aircraft anywhere in the airport at the area speed limit of about 20 mph (32 km/h). The vehicle needs less than one minute to securely engage the airplane, which helps speed airport operations and may be the quickest among aircraft tractors.

Goldhofer specializes in providing heavy-duty and special transport vehicles for over-the-road, off-highway, and airport applications. It has supplied more 35,000 vehicles for use in more than 160 countries, including more than 6,000 aircraft tractors.

“With the Phoenix, we wanted to get away from the general trend of over-engineering,” says Stefan Fuchs, chairman of Goldhofer. We concentrated on that which is essential and focused on the highest availability, reliable technology, and minimum maintenance expenditures.” The result is a completely new, compact and modular vehicle concept that sets high standards in user benefits and functionality for drive, steering, and braking.

The towbarless Phoenix tractor from Goldhofer is able to transport more than 80% of all commercial aircraft used worldwide.

The tractor’s hydraulic system requires rugged connections to prevent damage from the vibrations that can occur as an aircraft is being transported. Corrosion protection also is important for system components that are exposed to environmental extremes and aggressive deicing agents used in winter.

Receiving Mechanism Highlights Design Approach

Striving for lean design, Goldhofer completely redesigned the vehicle’s receiving device. For instance, where some previous models had used 14 hydraulic cylinders, the Phoenix needs just eight. Its hydraulic circuit design provides free access to all critical maintenance points.

Because it’s usually less expensive to use hose for hydraulic lines instead of metal tubing, a current trend for most OEMs is to replace tubing with hose. Goldhofer, however, bucks the trend by specifying rigid piping. “We largely forgo hoses because they are very maintenance intensive,” explains Fuchs. “On the other hand, tubes only need to be sensibly mounted right from the start.” The benefit for Goldhofer’s customers is lower total cost of ownership from less downtime and lower maintenance cost, especially when hoses must eventually be replaced.

Tube-connection technology takes on an important role within the hydraulic system for Goldhofer to achieve its goal of low-maintenance, leak-free systems that work reliably for the entire life of its vehicles. For this application, Goldhofer relies on soft-sealing ES-4 cutting rings from VOSS Fluid GmbH, Wipperfürth, Germany, to protect hydraulic connections from leaks and corrosion.

“We made our decision in favor of this technology after running numerous tests and suitability inspections,” says Fuchs. VOSS Fluid also supplies a pre-assembly device that minimizes installation time for these components and prevents errors.

High Fatigue Strength and Leak Resistance

The soft-sealing ES-4 cutting rings provide permanent and secure tube retention and high leak resistance even under continuous dynamic loads. They are used at multiple hydraulic connection points on the Phoenix, including its pre-assembly plate, which is a major component in the nose wheel receiving mechanism.

The hydraulic systems in Goldhofer’s AST-2P/X aircraft tractor incorporate the soft-sealing ES-4 cutting ring from VOSS Fluid for long life without leakage.

Among the advantages of the cutting-ring design are reliability and leakage prevention, thanks to its double-cutting ring technology and two integrated soft seals. In addition, the connection system’s block stop protects against over-assembly. By distributing load across two edges, the connection provides especially high fatigue strength. The first edge ensures secure retention of the tube, and the second edge prevents tearing during fluid shocks. Together, the features also minimize leak potential.

Furthermore, the body of the cutting ring incorporates a spring effect that prevents resettling, which can otherwise be caused by vibrations. This feature effectively withstands vibration for extended periods, such as those that can occur while towing an airplane for long distances across an airport.

Two fully enclosed fluoroelastomer seals are included in the secondary section of the cutting ring to seal potential leakage paths to the tube and the connection piece, in case any hydraulic fluid migrates past the metallic seal. VOSS Fluid guarantees long-term stability of the elastomers because of the material’s proprietary composition and the placement of the soft seals inside the cutting ring for protection.

Fast, Precise Assembly

When selecting the components, Goldhofer also demanded maximum reliability for pre- and final-assembly. Statistics show that more than 90% of all hydraulic system leaks can be attributed to connections on faulty assemblies. To proactively minimize these risks, the company’s specialist for special transport vehicles specified Voss Type 90 Comfort pre-assembly machines. These devices incorporate error-detection and automatic pressure-setting capabilities. They identify missing or incorrectly inserted cutting rings before assembly and prevent over-assembly and under-assembly.

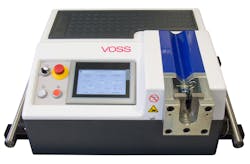

The Type 90 Comfort pre-assembly machine incorporates error detection and automatic pressure setting for fast, reliable assembly of hydraulic fittings.

Goldhofer mechanics simply tool-up the pre-assembly device with the appropriate VOSS tool, which comes with a standard RFID chip. The RFID reader integrated in the device reads the chip and automatically sets the correct assembly parameters. Then the pre-assembly process, which is fast and reliable, begins immediately. The ES-4 cutting ring is mounted on block stops to eliminate errors in the final assembly process. Application force reaching a predetermined value indicates that assembly is correct and complete.

Long-Term Corrosion Protection

Because aircraft tractors are used under all weather conditions and are exposed to aggressive deicing agents in winter, Goldhofer has uncompromising requirements for corrosion protection. “All of our system components are designed with the highest degree of corrosion protection,” says Fuchs. “Naturally, that also applies to tube connections and makes the entire system more resistant to mechanical stress and aggressive media.”

All hydraulic lines on the Phoenix are electrogalvanized and have an additional protective organic coating. Tube fittings also are protected with a zinc-nickel finish. For the ES-4 cutting rings, this long-term corrosion protection, VOSS coat, achieves the highest Corrosion Protection Class of K5, according to VDMA Standard Sheet 24576. On top of that, the coating significantly exceeds the required resistance values against white and red rust.

For more information, call Voss Fluid USA at (260)373-2299, or visit their website at www.vossusa.com.