Researchers at the U.S. Department of Energy’s (DOE) Pacific Northwest National Laboratory have found that adding graphene to copper wiring can improve the performance of electric motors and other applications.

Graphene is comprised of pure carbon and extracted from graphite; it is known for being a light but durable material which can be utilized in various applications.

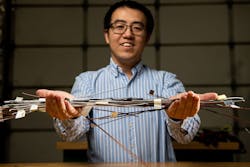

Materials scientist Keerti Kappagantula and her colleagues at Pacific Northwest National Laboratory (PNNL) discovered that by adding graphene to copper, it was possible to improve the metal’s temperature coefficient of resistance – a concept which explains why metals like copper get hot when electric current runs through them.

If too high a temperature is reached, performance issues can occur. This is one of the concerns with electric motors, a common user of copper wiring.

Understanding this issue, Kappagantula and her colleagues have been researching ways to reduce the temperature coefficient of resistance while also enhancing the ability of a metal to conduct electricity which can provide further performance improvements. The key question in their research has been whether the addition of other materials to a metal could increase metal conductivity, and if that could be done at high temperatures.

Adding graphene to the metal was the answer to achieving both aspects.

What are the Benefits of Using Graphene?

The researchers at PNNL found that adding 18 parts per million of graphene to electrical-grade copper reduced the temperature coefficient of resistance by 11% without decreasing electrical conductivity at room temperature. Maintaining or even improving electrical conductivity can benefit efficiency.

It was noted in the PNNL press release announcing findings of the research that for electric motors used in electric vehicles, an 11% increase in electrical conductivity of copper wire winding translates into 1% gain in motor efficiency. And the more efficient the motor can be, the less energy it drains from the vehicle’s battery.

According to Kappagantula, graphene has very high electrical conductivity compared to copper. “So, using it as an additive in copper to improve its conductivity is beneficial to create pathways for electrons to zoom through during energy transport,” she said in an interview with Power & Motion.

This will benefit copper electrical wiring used in electric motors as well as that used to distribute energy throughout homes and businesses.

She said the biggest benefit provided by use of graphene with copper wiring will be the ability to achieve higher electrical conductivity at elevated operating temperatures. This could help overcome current challenges with electric motors which have to be kept within a certain operating temperature range. If they get too hot, electrical conductivity drops and performance is negatively impacted.

However, with the addition of graphene in the copper it could be possible to maintain conductivity even if higher operating temperatures are reached.

To date, Kappagantula said electric motor designers have had to deal with copper losses as a given issue in designing a motor. As a way of overcoming this, they have enhanced their thermal management solutions to lower temperatures within motors. “Our composites can decrease thermal losses, which can provide additional design freedom for motor designers,” she said.

Kappagantula also noted that it could be possible to improve the mechanical properties of copper through the addition of graphene which could offer further performance benefits as well.

READ MORE: Improve Electric Motor Efficiency with Increased Phase Counts

Overcoming Preconceived Notions of Metal Additives

The integration of additives into metal typically increases its temperature coefficient of resistance. But the copper-graphene composite wiring developed by the PNNL researchers demonstrates the opposite is actually possible.

The Next Steps for Bringing Copper-Graphene Composite Wires to the Market

Kappagantula sees her team’s findings benefiting a range of applications in which electricity is used, including electric motors and electrical wiring for buildings. For the latter, a more conductive copper wire could help better meet the increasing demand for electric power in cities – which are expected to continue growing in size over the coming years – while doing so more efficiently.

The team is working on further customization of the copper-graphene material as well as measuring other necessary properties including strength, fatigue, corrosion and wear resistance. Understanding these will help ensure it can be used in various market applications.

In addition, Kappagantula said the team is scaling up its manufacturing capabilities as well as working with motor wire manufacturing facilities to determine how the insulation coating typically seen for electric motor wires will affect the composites’ electrical performance.

“There is always more research to pursue in this area, where we are constantly looking for other, better process windows and composite formulations that result in even higher electrical performance improvements,” she concluded.

READ MORE: Consortium Designs Agile, Digital Production System for Electric Motors

Editor’s Note: Power & Motion's WISE (Workers in Science and Engineering) hub compiles our coverage of workplace issues affecting the engineering field, in addition to contributions from equity seeking groups and subject matter experts within various subdisciplines.