CES 2025 Spotlights Heavy Machinery Industry's Advancements in Electrification and Automation

Although CES (Consumer Electronics Show) began as an event focused on consumer electronics, it has evolved to become one of the largest tech events in the world highlighting developments in a range of industries.

Over the last several years many heavy truck, construction equipment and agricultural machinery OEMs, as well as component suppliers serving those markets, have begun exhibiting at the event to showcase the technological advancements taking place in these industries. At CES 2025, Volvo Group President & CEO Martin Lundstet gave a keynote speech on the need to create more sustainable and efficient methods of doing work through the use of electrification, connectivity and automation — areas in which the OEM has been investing many of its R&D efforts for its truck, construction and mining equipment brands.

With these and other customer sectors important to the fluid power and electromechanical motion control industries being present at the event, CES has become a show to watch to help offer insight into the technologies and trends influencing future component and system designs.

Given the show's growing importance, we've collected news highlights from relevant companies exhibiting at CES 2025 which focused on some of the top trends influencing the majority of industries today including artificial intelligence (AI), sustainability, mobility and the energy transition were some of the top trends of focus at this year's event.

Schaeffler Highlights Expanded Range of Motion Technology

During CES 2025, Schaeffler exhibited its expanded range of motion products which it achieved through the recent merger with Vitesco Technologies. The merger has enabled the company to add manufacturing capacity as well as research and development capabilities, allowing it to now serve the motion needs of various applications.

To demonstrate its expanded range, Schaeffler's exhibit at CES was comprised of the following areas:

- Humanoid Technology – This portion of the company's exhibit booth included an interactive display of its technologies for advanced robotics.

- Dynamic Performance Vehicle – Another interactive display, this segment of the exhibit highlighted the full range of chassis and electrified powertrain technologies now available, due in part to the Vitesco merger. All vital components for an electric powertrain can be sourced from the company for everything from passenger cars to heavy-duty vehicles.

- Motion Hub – Within this hub, Schaeffler showed the eight motion technology product families it offers and how they can work together to meet the requirements of various industries.

Also displayed at CES 2025 was Schaeffler's battery developments, including those for solid state batteries, as well as its production technology capabilities which take advantage of AI to enable automation and efficiency in manufacturing environments. For the latter, Schaeffler showed how it is applying its motion expertise to mobile robots with EMMA, a mobile cobot.

Caterpillar Launches Centennial Celebration

Caterpillar Inc. used CES to kick off celebrations for its 100th year of business. While reflecting on the innovations made over the last century, the company also used its exhibit at the show to highlight what may be in store for the construction and mining equipment industries in the coming decades.

The company's CES exhibit, entitled "The Next 100 Years: Experience What's Possible," highlighted the various technologies being offered to aid the energy transition taking place in the heavy equipment, and many other, sectors. A key piece of the exhibit was a 55,000 lb. Cat 972 Wheel Loader with demonstration Extended Range Electrified Machine hybrid retrofit.

Per the company, the demonstrator maintains or exceeds performance similar to a diesel machine and does not require DC charging, helping to minimize or completely eliminate the need for additional electrical infrastructure at job sites which is one of the challenges associated with electrification of off-road machinery. Unlike other battery electric machines, the demonstrater features an additional power source. "In this case, it’s a conventional diesel generator running AC power to a rectifier, which converts energy from AC to DC. The energy created is used to charge the battery, drive the machine or both," said Rob Janssen, vice president and general manager of Caterpillar’s Electrification + Energy Solutions division.

Additional technologies showcased were Cat Command, the company's technology for remote machine operation. As it has done at many other industry events, Caterpillar had a remote operating station set up at CES from which attendees could operate Cat machines working at the company's Tinaja Hills Demonstration and Learning Center in Green Valley, AZ, 445 mi. away.

Caterpillar intends to continue celebrating its 100th anniversary throughout 2025, which has already included events at facilities in the U.S. On January 9, the company kicked off its Centennial World Tour during which it will visit company facilities around the world and provide interactive experiences for employees as well as visitors.

Mahle Showcases Electrification Solutions at CES

Technology company Mahle showed several products to aid with vehicle electrification, including those for ensuring efficient thermal management — an important aspect for optimized performance.

Among the electric vehicle solutions on display was the company's new technology kit for electric motors which combines the advantages of Mahle's Superior Continuous Torque (SCT) and Contactless Transmitter (MCT) electric motors. This allows for the creation of a component offering high-peak power, contactless and wear-free power transmission while eliminating the use of rare earth metals and increasing efficiency.

On the thermal management side of things, Mahle featured two of its newest products, a bionic fan and a bionic battery cooling plate. For the fan, the blades are designed to reduce noises under full load and when charging vehicles. The blades were optimized using AI and take their inspiration from owl wings which are known to be the quietest in the bird world.

The bionic cooling plate is designed to enable fast charging, long cruising ranges and long service life for sensitive lithium-ion batteries. According to the company, the cooling plate provides a 10% increase in cooling performance and reduced pressure loss of 20%.

Mahle also showed its next generationa refrigerant thermal management module and e-compressor at CES 2025 as well as wireless charging technology.

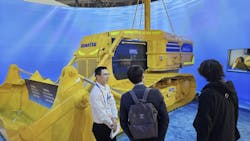

Komatsu and Oshkosh Make CES Debut

Heavy equipment OEMs Komatsu and Oshkosh Corp. were among the companies who exhibited for the first time at CES.

In a pre-show press release, Komatsu noted it is exhibiting at CES not only to showcase the innovative technologies it is developing — including those for remote operation on a lunar environment and underwater automation — but also to attract new generations of talent and industry partners.

"Our core industries employ some of the most innovative, ground-breaking applications of automation and connected products, but new generations of talent with the skills to further those innovations often do not realize the opportunities we have available that would allow them to shape modern advancement," said Hiroyuki Ogawa, President and CEO of Komatsu Ltd. "At CES 2025 we are looking forward to bringing some our most interesting equipment and technology applications to life for attendees from across the globe."

At its CES 2025 booth, Oshkosh Corp. focused on advancements in electrification, AI, autonomy, connectivity and analytics. These are all being applied to the various industries the company serves, including airports, construction equipment and refuse vehicles, among many others.

The company's exhibit showed how it is using these technologies to help create safer, more efficient and productive operations.

Read More CES 2025 News from Other Endeavor Business Media Publications

CES 2025: Behind the Scenes from Electronic Design

Oshkosh AeroTech to Showcase Advanced Aviation Solutions at CES 2025 from AviationPros

Pierce Joins Oshkosh to Showcase the Future of Electric Firefighting Technology at CES 2025 from Firehouse

John Deere Shows New Autonomous Machines & Technology at CES 2025 from Rental Equipment Register

VicOne and MediaTek demonstrate cybersecurity with automotive telematics at CES 2025 from Security Info Watch

Volvo: Transportation and logistics are critical to our modern and future worlds from FleetOwner

"Oshkosh has a clear purpose: to serve people who do the toughest work in our communities and make a difference in people’s lives," said John Pfeifer, president and chief executive officer, Oshkosh Corporation. "At CES, our booth will showcase how we’re harnessing cutting-edge technology to transform airport gate and ground operations, enhance essential services that impact everyday life in our neighborhoods and redefine efficiency and safety on job sites."

John Deere and Kubota Demonstrate Automation in Agriculture

Autonomy remains an important development area for much of the heavy equipment industry, including agricultural machinery, as a means of overcoming the skilled labor shortage facing this sector. Both John Deere and Kubota showcased the strides they are making in autonomy for agriculture as well as the other heavy machinery markets they serve at CES 2025.

John Deere introduced the second generation of its autonomy kit which includes advanced computer vision, AI and cameras to enable safe navigation of work environments. The company introduced its first autonomous tractor at CES 2022. Since then it has continued to advance the technology, culminating in the second-generation kit which will available for retrofitting onto certain existing John Deere machines.

In addition, the company announced it has expanded autonomous operation capabilities to other machines including:

- Autonomous 9RX tractor for large-scale agriculture

- Autonomous 5ML Orchard Tractor for Air Blast Spraying

- 460 P-Tier Autonomous Articulated Dump Truck (ADT) for Quarry Operations

- Autonomous Battery Electric Mower for Commercial Landscaping.

"Our agriculture, construction, and commercial landscaping customers all have work that must get done at certain times of the day and year, yet there is not enough available and skilled labor to do the work," said Jahmy Hindman, Chief Technology Officer at John Deere. "Autonomy can help address this challenge. That’s why we’re extending our technology stack to enable more machines to operate safely and autonomously in unique and complex environments."

Kubota's CES exhibit included advancements the company is making in autonomy as well as more diverse powertrain options, connectivity and data analytics for agriculture, construction and mowing. As such, it showcased several new developments including:

- Agri Concept 2.0 – An electric tractor concept offering data, AI, automation and electrification as a choice of powertrain for when you want to drive and autonomous when you don't.

- Smart Autonomous Sprayer – A fully autonomous chemical sprayer that scouts to identify pests and sprays with precision to lessen spray drift and overuse. The result reduces labor and the use of chemicals in the field.

- KATR – The Best of Innovation winner in the CES Innovation Awards 2025 program, the Industrial Equipment and Machinery product category, Kubota's four-wheeled all terrain, multifunctional robot. The KATR maintains a level cargo deck when working on uneven terrain and can work autonomously or remotely to tackle a range of versatile applications in agriculture and construction environments.

- Kubota KX038-4e electric excavator, a zero-emissions, quiet electric excavator that addresses ventilation, noise, and emissions allowing for work at night, in residential areas, or even indoors.

- Smart Autonomous Zero-Turn Mower showcasing Kubota's cooperative technology that facilitates multiple machines working together to complete large tasks and makes it possible to do more with smaller machines, less investment and risk than one industrial-sized machine.

About the Author

Sara Jensen

Executive Editor, Power & Motion

Sara Jensen is executive editor of Power & Motion, directing expanded coverage into the modern fluid power space, as well as mechatronic and smart technologies. She has over 15 years of publishing experience. Prior to Power & Motion she spent 11 years with a trade publication for engineers of heavy-duty equipment, the last 3 of which were as the editor and brand lead. Over the course of her time in the B2B industry, Sara has gained an extensive knowledge of various heavy-duty equipment industries — including construction, agriculture, mining and on-road trucks —along with the systems and market trends which impact them such as fluid power and electronic motion control technologies.

You can follow Sara and Power & Motion via the following social media handles:

X (formerly Twitter): @TechnlgyEditor and @PowerMotionTech

LinkedIn: @SaraJensen and @Power&Motion

Facebook: @PowerMotionTech