High Modulus Plastics for Off-Highway Equipment

Off-highway vehicles operate in conditions that challenge hard-working components and the materials they are made of. Those vehicles and ancillary equipment must withstand summers in the Australian Outback, with its 130°F temperatures, as well as travelling though Siberian snowstorms at −60 ºF. They can also be found on mining sites where they are exposed to sulfuric acid, which can severely damage polymer-based parts such as guide rings. And maintaining this off-highway equipment in extreme conditions is a challenge. So low-maintenance, long-life parts are a must; they can make the difference between hitting a deadline or paying a late fine.

One group of materials that stands up to such conditions are high-modulus thermoplastics. The elastic modulus (stress/stain) is a mechanical property that measures a material’s elasticity; the higher a material’s modulus, the more stress, or force, is needed to deform or compress it.

Base Polymers and Fillers

Although there are three main groups of high-modulus plastics—amorphous thermoplastics, imidized materials and semi-crystalline thermoplastics—only the third one has affordable materials suitable for processing into guide rings, bearings, back-up rings and structural components.

Within semi-crystalline thermoplastics, several base polymers are commonly used in extruded parts for use in off-highway hydraulic systems:

- Polyamide (PA or Nylon)

- Polyphthalamide (PPA)

- Polyetheretherketone (PEEK)

- Polyoxymethyline (POM or acetal)

- Ultra-high-molecular-weight polyethylene (UHMW-PE)

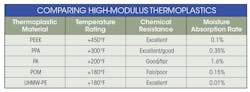

These polymers vary in terms of temperature resistance, tensile strength, flexural modulus (bending stiffness), Izod impact (toughness/resistance to impact) and chemical resistance. For example, PEEK materials are extremely strong and temperature resistant, but UHMW-PE is tough and abrasion resistant.

Several different fillers are used to add strength or modify the tribological effects of these thermoplastics. For example, adding a polytetrafluoroethylene (PTFE) powder to the pellets used in injection molding can reduce friction and improve the wear characteristics of PEEK materials. And adding molybdenum disulfide (moly) to nylon leads to a harder and more wear-resistant surface.

Glass or carbon fibers can be added to thermoplastics to add strength. A common example is adding glass to PA to enhance strength and reduce the amount of water the final product will absorb. Similarly, adding carbon fiber to a PEEK improves wear properties and extend the life of components such as guide rings in high-temperature applications.

Generally speaking, the higher the temperature resistance and strength of one of these thermoplastics, the higher the cost. For example, PEEK materials are extremely strong (operating stress of up to 11,000 PSI) and resist temperatures up to +450ºF. However, this performance comes at a cost. For some applications, the additional cost is worth it; for others, it may make sense to instead use a POM (acetal), UHMW, or a PA with a filler such as glass.

Components such as guide rings, bearings/bushings, back-up rings and structural parts can be created from high-modulus thermoplastics and will be lighter than their metal counterparts. Individually, the weight difference per part is negligible, but changing using thermoplastic instead of steel components that are used in several places on a piece of equipment can reduce overall weight significantly. For example, a shoe pad used in four to six locations on a forklift is traditionally made of cast steel. They can be replaced with glass-filled nylon pads that still withstand the same impacts and loads as the steel component but at 1/6th the weight.

Additionally, high-modulus plastic rings can be modified to include internal lubricants, letting them be used in systems that don’t require petroleum-based greases and are more environmentally friendly.

Other components that could benefit from being made of high-modulus thermoplastics include:

Guide rings made with thee plastics can be designed to absorb side load forces in pistons and rods in hydraulic cylinder while eliminating metal-to-metal contact. They also provide a coefficient of friction, a long service life, good chemical resistance, and high load capacity, as well as a lower wear-rate than metal. The guide rings can be purchased with an angled cut for linear motion, a straight cut for rotary motion or a step cut for special applications.

Bearings and bushings of plastic, like guide rings, prevent metal-to-metal contact and reduce friction, extending the life of non-hydraulic systems.

Back-up rings are installed in grooves to protect and support elastomeric seals and stop them from being pushed into the sealing gap. They are often used in hydraulic cylinders for excavators and agricultural machines.

Structural components made of plastic for off-highway vehicles, such as wear pads and thrust washers, are lighter and often less expensive than those made of metal.

For off-highway parts that need a combination of properties of high-modulus thermoplastics and those of other polymers, co-injection might be the answer. It combines two polymers in single operation to create a multi-functional component. One example would be an elastomeric material that acts as a seal and a scraper combined with a stronger thermoplastic material that could act as a bushing or guide ring. This component would be an ideal molded rod end in a hydraulic cylinder for an excavator bucket on an off-highway vehicle.

Although the technology for these types of co-injection operations exists, it can be challenging for designers to understand how to use it most effectively. To get the expertise, companies should work with a supplier with experience with co-injection molding.

Tom Zozokos is a product line director and Beth Figliulo is the fluid power segment manager/Americas for Trellborg Sealing Solutions.