Joystick controls

Manufacturers and operators of mobile equipment like joystick controls because they give the operator a feel for his command - the greater the displacement of joystick, the greater the response from the actuator. Some approaches to interfacing hydraulic valves with joysticks include:

- mechanical linkages,

- hydraulic pilot circuits, and

- electrical commands to electrohydraulic valves.

With mechanical linkages for commanding hydraulic valves via dual-axis joysticks, the apparent disadvantage is the complexity of the linkage arrangement, making it difficult to install and adjust. The simplest linkages are levers and rods, but these become cumbersome if a straight path from the joystick to the hydraulic component does not exist. When the mechanical linkage must be routed over, under, around, or through obstacles, mechanical push-pull cables have found favor.

All mechanical linkages may require operators to generate objectionable high actuating forces if the mechanical advantage of the assembly is not designed in. Otherwise, operator fatigue may result. And as with all mechanical arrangements, regular lubrication and adjustment for wear may be necessary. A neater arrangement uses hydraulically piloted valves and joysticks. With this setup, low-pressure fluid is routed to the joystick, which, in turn, routes fluid to the appropriate pilot-operated hydraulic devices based on joystick position The advantages of this system over a mechanical linkage arrangement are simplified installation, lower actuating force required by the operator, and less maintenance.

Among the disadvantages of piloted joysticks are the potential for leakage, noise, and heat from hydraulic fluid in close proximity to the operator. In winter weather, cold oil adversely affects response and increases operator effort. Hydraulic pilot installation still involves the routing of multiple hoses or soft-metal tubing.

An electric joystick uses a power supply and sends electric signals to command an electrohydraulic valve. Because thin wires are so much easier to route through a machine than mechanical cables, hoses, or tubing is electric joysticks greatly simplify installation and and provide the freedom of remote mounting. Serial communications make this process even easier. The valves can be located extremely far from the joystick. The principal disadvantage of the electric joystick has been the higher cost of electrohydraulic valves over their manually driven or pilot-operated counterparts. The cost trade-off between hydraulic and electric joysticks is about even.

Electric joysticks

There are two major categories of electric joysticks displacement and non-displacement. The displacement type uses the motion of a lever, transducing that motion eventually into an electrical output. The non-displacement type has a lever similar to the displacement type. However, the motion of the joystick is not transduced directly to an electrical output. Instead, the force applied to the lever is transduced via a strain gage or similar medium to electrical output. An advantage of the non-displacement joystick is the absence of moving parts. A disadvantage is the loss of tactile feedback to the operator normally associated with the motion of a joystick.

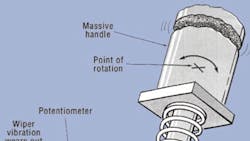

The two popular designs of displacement-type joysticks are potentiometric movement and inductive coupling. The potentiometric joystick, Figure 1, uses a rotary or linear potentiometer to convert mechanical displacement to electrical output. The conversion from curvilinear motion of the joystick lever to potentiometer movement usually involves shafts, gimbals, gears, and torsion springs. These mechanisms contain many parts, which can make these joysticks vulnerable to damage and shortened lifespan - especially if they are exposed to machine vibration.

Potentiometric joysticks are available in high-cycle-life construction with published life in excess of 106 full cycles. Most joysticks spend the greater part of their working lives in a neutral position, with the wipers of their pots being dithered continuously due to the vibration of the machinery onto which they are mounted and the mass of the control levers. This low amplitude cycling (dithering) of the pot wiper may prove more destructive to the pot than full-cycle stroking would. The constant dithering and high accumulation of cycles over a narrow area may cause the conductive element to wear-in locally, causing a "dead" or "noisy" spot.

Inductively coupled movement

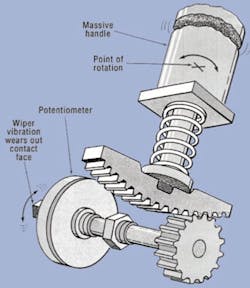

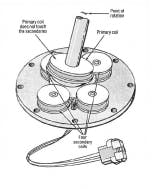

An inductively coupled joystick uses a variable-transformer-type relationship. A primary coil sets up a field that is induced into a set of secondary coils. Through movement of either the drive coil or a ferrous shaft, which commutates the field, the induced field will vary proportionally. The closer the drive coil is to a secondary coil, the stronger the pickup field. The secondary coil that is farther away from the primary coil will have a proportionally smaller pickup. Figure 2 shows the relationship of primary and secondary coils.

The principal advantage of this mechanism is that there are no contacting or wiping electrical parts. Further, the mechanical complexity is much less. The model shown in Figure 2 has only three moving parts (lever, centering cup, and helical compression spring), so life of the control is significantly extended.

Protection from stray electrical fields affecting the joysticks inductive field is provided by a synchronous detection system. The pickup from the four secondary coils must equal the induced signal provided by the primary, so the effects of adjacent electrical fields essentially are ignored.

Hall-effect technologyDevelopment of newer joystick technology has focused on enhancing linearity and electromagnetic immunity while providing additional output capabilities within a smaller working envelope. One significant technology - the Hall effect - has emerged as being completely capable of providing all these desired attributes and enhancements.

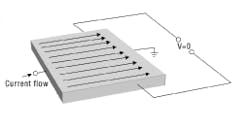

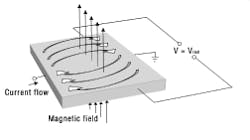

If a magnetic field is present when an electrical current flows through a conductive material, the electrons are uniformly distributed throughout the conductor, Figure 3. Introducing a magnetic field to the electric current disrupts the current and causes its course to be changed, Figure 4.

When the input current is held constant, as in a joystick application, the Hall voltage is directly proportional to the perpendicular component of the magnetic field. Therefore, if the magnets change position, the voltage changes and can be quantified as joystick movement.

Additional axes

The mechanical simplicity of the inductively coupled joystick movement lends itself to incorporation of multiple movement axes. The traditional two-axis joystick can have a third or even a fourth axis added to it, retaining the basic mechanical simplicity, yet having no wiping contacts. For example, a twist movement of the handgrip may produce a third axis, and a thumb-operated wheel can provide a proportional fourth axis. A grip-mounted switch could also be incorporated to add simple functionality.

Joysticks with inductively coupled movement have been replacing the more traditional models on continuous duty cycle applications - such as large excavators used in strip mines. These applications and other have found electric joysticks, particularly the inductively coupled type, to enhance their reliability.

Joysticks with inductively coupled movement have been replacing the more traditional joysticks on continuous duty cycle applications - such as large excavators used in strip mines and aerial basket controls for utility trucks using fiber-optic couplings. These and other applications have found electric joysticks, and more particularly the inductively coupled type, to enhance their reliability.

This information was provided by Douglas D. Schumann, president, P-Q Controls Inc., Bristol, Conn.