We have been covering (mostly) square shaped hydraulic symbols. We'll move on to diamond-shaped symbols, which according to the Organization internationale de normalisation, represent conditioning apparati. OK, so apparati isn’t a real word, but why should cacti have all the fun?

A diamond is drawn in symbology simply as a square-tilted forty-five degrees onto its corner. Yes, this is grade-two elementary review of geometry, but stick with me. By conditioning apparati, I’m referring to components, which help modify or control the condition of fluid, be it either oil or air. These components include filters, coolers, heaters – and to be faithful to pneumatics, which is under the Fluid Power (Tips) umbrella – separators, dryers and lubricators.

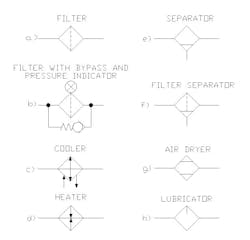

If you look at the drawing example a) shows a standard symbol for a filter, applicable to both hydraulics and pneumatics. The dashed line bisecting the diamond depicts filtering media, which can be screens, mesh, holes, pores, fiber or foam. Regardless of the filter media, understand that particles of some sort will be trapped as they pass through the filter.

Example b) shows the symbol often used in a hydraulic filter application. The basic diamond and dashed line are there, but the symbol has a couple additions. The first is the bypass check valve. This is a spring biased check valve which stays closed under normal conditions. When pressure rises to the value of the check valve spring, the valve opens and bypasses fluid past the element. This prevents excessive tank line backpressure as a result of a clogged filter. It is important to monitor the backpressure created by the filter, so…

The quadrisected circle perched on the diamond is the symbol for a pressure indicator. This symbol is not to be confused with a pressure gauge symbol. Although a pressure gauge symbol is a pressure indicator, often the pressure indicator on a filter is simply a pop-up button or even a lamp. This is also called a “clogging indicator,” which warns us if the differential pressure through the filter is too high, signalling a clogged element. Generally, the clogging indicator should “trip” or warn you in some way when the element is about two thirds clogged, giving you time to change the element before the filter goes into bypass.

The next two diamonds refer to temperature conditioning. Just like the engine in your car, a hydraulic system works most effectively and efficiently within a specific temperature window. We like it to be warm, but not too warm. To prevent excess heat from building in the hydraulic system, we can use a heat exchanger. Heat exchangers are generally considered to be oil-to-liquid type, rather than oil-to-air style. However, technically, you’re still exchanging heat with the air.

Basic oil-to-liquid coolers are represented in example c). Imagine oil flowing across the horizontal line, and the up/down arrow shows us heat is being removed from the oil outward. The additional arrows below the diamond reflect the coolant flow (which can also just be water), especially important if you want to convey a complex cooling circuit with valves and thermostatic control.

Example d), as I’m sure you can easily figure out, is a heater. With all other things being equal, this one shows the inward arrows adding thermal energy to the hydraulic oil. I have left out the coolant flow arrows, which is common, meaning the coolant circuit isn’t specified.

I apologize to all you pneumatics fans out there, as it has taken this long for me to write about the topic. The next four symbols describe various components in pneumatic conditioning apparati (I’m determined to receive future etymological credit for that word).

Example e) is a separator; water specifically. You can picture the triangle at the bottom being pooled water dripping out the bottom. If you had a triangle within a triangle, this would represent an automatically draining separator.

Often, a filter and separator are in the same assembly, and this is shown in example f). The symbol is self explanatory, being based on two already discuss symbols.

Example g) is an air dryer, which can either be the chemical/desiccant type or electric. I suppose the symbol is showing water being pulled away from the oil path, but as a pictogram, it is less clear as other symbols.

Finally, we come to the last pneumatic conditioning unit commonly used, and that is the lubricator in example h). Not every system, or part of every system requires constant oiling, but they can be critical for valves, actuators or tools which need lubrication for their reliable operation. You wouldn’t want to have a lubricator in the sub-circuit of your pneumatic system terminating in your paint booth, but definitely in your air assembly area taking advantage of air grinders or impact wrenches.

About the Author

Leaders relevant to this article: