Efficiency is an absolute requirement for manufacturing in terms of productivity and financial success. That is why most manufacturers go to great length to ensure their assembly lines are laid out in carefully designed configurations, workers and machine operators are strategically placed, and material and labor waste minimized.

Yet, one area of manufacturing in need of efficiency gains is one of the most overlooked, namely, joining subassemblies of multi-ton machines.

Problems with Cranes

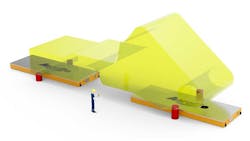

Cranes have been traditionally used to join large and massive subassemblies, oftentimes two halves of the final machine. In this process, one subassembly, which can be as large as a house and weigh up to 50,000 lb, is suspended and lowered by a crane to line up with a matching subassembly. This is a time-consuming maneuver that creates unacceptable risks of injuries to workers, damages to the subassemblies and surrounding equipment, and a major loss of productivity.

In a typical real-world example, a defense contractor that made large, armored vehicles regularly maneuvered a multi-ton sub-assembly hanging from a crane to line up with its mate, another massive sub-assembly on a stationary table, so technicians could join the two. This meant those technicians had to relay instructions to a distant crane operator.

The operator had to move the crane and assembly painstakingly slowly to keep the load from swinging out of control and colliding with surrounding equipment or workers. This meant the operator was forced to wait until the load’s center of mass settled between small, incremental moves to ensure safety. As a result, the entire process routinely took hours to complete—an unacceptable amount of time.

Despite taking the time to be extra cautious the company still couldn’t fully eliminate the risk to workers and equipment posed by those multi-ton suspended loads. The slightest wrong movement or minor equipment failure could injure or kill someone.

The company was aware of the U.S. Bureau of Labor Statistics’ reports of dozens of workers dying each year and hundreds more injured in crane-related accidents. Little wonder that the manufacturer eventually eliminated both cranes and suspended loads for equipment mating and switched to air-caster-powered transporters that could safely get the job done, and in minutes rather than hours.

The full assembly can then be driven through the rest of the manufacturing process on the air transporter. Efficiency goes up, process costs go down and safety hazards are significantly reduced—altogether producing superior results when compared with crane operations.

Workers join the two subassemblies into one piece, enabling the transporter to drive under both and safely move the fully assembled structure.

That’s good news for workers who no longer have to worry about loads suspended above their heads.

Air Caster Technology

An air caster’s main component is a durable, flexible, doughnut-shaped airbag that can be inflated with compressed air. It is affixed to a metal housing that supports the load. The airbag is inflated with standard plant air at about 90 psi. Once the airbag fills and reaches its maximum expansion, excess air is channeled between the floor and caster, creating a film of air that is as thin as a business card. The load then literally floats atop that film with the casters lifting the load no more than an inch or two.

Air casters work on the same basic physical principles as a hovercraft or the puck in an air hockey game. A thin film of air lowers friction coefficient between load and floor to less than one percent, so even extra heavy loads can be easily moved by a single worker. In fact, depending on floor conditions, a single operator exerting no more than 25 lb of force can move a 5,000-lb load over a surface that slopes 0.25 in. in. 10 ft. And operating the casters requires only basic instruction; there is no need for certification or formal licensing.

Floors should ideally be flat, continuous and solid to get the best performance from a set of air casters. About 90% of applications are on standard factory smooth concrete floors. If the casters pass over cracks, bumps, gaps, joints or other irregularities, they may not be able to maintain enough sufficient air pressure to create the film of air. Such floor imperfections can be corrected by using overlays or other techniques.

Air casters fit beneath the load, enabling the load to be moved in any direction or rotated in place for precise positioning. They can also be differentially inflated so that casters under the front of the load are slightly deflated compared to those under the rear of the load. This lets workers slightly tilt a subassembly and align it to mate with another subassembly.

Air casters can be built into transporters that include drive and power subsystems, operator handles, throttle controls and no-load wheels to ease handling and direction control.

Downstream Productivity Gains

Air casters did more for the defense contractor than expedite equipment mating; they helped completely revamp the whole workflow.

Air casters potentially enable wholesale changes to the duration of the assembly line process. Because they maneuver through narrower corridors, make 90-deg. turns, rotate in place and can be precisely positioned by hand, the manufacturer could completely reconfigure individual workstations for maximum efficiency. In the event of future changes, they can be further reconfigured without the stresses or limitations associated with crane accessibility.

Easing the Mating Process

Flexibility is paramount for successfully enacting lean manufacturing methodologies and other approaches to increase efficiency, throughput and plant capacity. The ability to re-design and re-sequence subassembly timing and workflow is key to reducing space, labor and time requirements. A material handling system that easily moves throughout a manufacturing facility is a vital tool for a manufacturer to maximize efficiency across the entire production process.

Air casters turn a laborious, potentially dangerous procedure into one that’s short, simple and safe. Fewer safety barriers are required, and workers handle multi-ton loads with greater peace of mind and confidence. The manufacturer can achieve bottom-line improvements from greater throughput.

Air casters have proven ideal for mating massive structures in manufacturing environments by dramatically reducing completion time from hours to minutes with a safer, more efficient assembly process from start-to-finish. They represent a material handling system proven to create and maintain a seamless assembly line process.

Mike Brown is a mechanical engineer and sales operations manager at AeroGo, Inc., Seattle.

About the Author

Leaders relevant to this article: