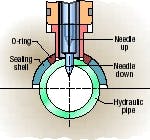

Cross-sectional drawing shows components of Serv-Clip-1 and how they establish an opening in pressurized hydraulic line for subsequent testing.

Cost-efficient products are always desirable in today's economy, but when such a product also claims to get the job done faster, it's certainly worth looking into. The Serv-Clip-1, from IC Fluid Power, Rossford, Ohio, promises both of these benefits to fluid power users.

The Serv-Clip is a pipe measuring connection that connects to a pipe to allow the user to take a variety of hydraulic system measurements: pressure, temperature, rate of flow, or fluid samples for subsequent particle counting. Pipes can be pressurized to 9100 psi and have diameters from 10 mm to 42 mm or 3/8 to 11/2 in., with wall thicknesses up to 3/16-in.

Once the Serv-Clip is placed into position on the cleaned surface of the pressurized hydraulic pipe, a center cylinder is screwed down. Then, a needle is pressed through the wall of the pipe.

Using the principle of plastic deformation, it creates an opening with an approximate diameter of 0.087- in. The cylinder head is then unscrewed, pulling out the needle, and leaving the pierced hole open so measurements can be taken. Once installed, the serv-Clip provides a permanent connection.

The entire connection process can be done without special tools and takes only a few minutes. The system is completely leak proof, thanks to a Viton O-ring designed into the system.

For more information contact IC Fluid Power at (877) 423-5843 or visit www.icfluid.com.