Industries such as energy, mining, construction, rail, waste management, agriculture, and oil and gas are loaded with mobile equipment. If you are faced with finding professional training for your fleet or unique mobile equipment, CFC Solar may be able to help. CFC-Solar is one of the most respected names in the mobile industrial training market with a history of developing training programs that teach individuals how to maintain today’s technically advanced mobile equipment. In addition to product specific training, CFC-Solar has standard training classes developed for the mobile industry that include:

• Level 1 Mobile Hydraulics – In Depth Fundamentals

• Level 2 Mobile Hydraulics – Advanced Maintenance

• Level 3 Mobile Hydraulics – Design and Sizing

• Troubleshooting Mobile Systems using Schematics

• Hydrostatic Closed Loop Systems

• Level 1 Mobile Electrical – Fundamentals

• Level 2 Mobile Electrical – Multiplex Systems

CFC-Solar is also one of the primary training firms in the world that provide Fluid Power Society Mobile Hydraulic Certification. For more information on our services, contact [email protected] or visit www.cfc-solar.com.

Find the solution

Think you know the answer? We’ll post this problem at fluidpower

talk.blogspot.com, and you can submit solutions there, or e-mail [email protected] with your solutions for a chance at a $50 gift card — we will randomly select a winner from all correct answers.

The correct answer will be printed on Jan. 3 at fluidpowertalk.blogspot.com and will be published in the next edition of “Troubleshooting Challenge.”

Congratulations to Howard Hurley, owner of Alacarte Engineering, LLC, Indianapolis, for providing the only correct answer to November’s problem. He won a $50 gift card.

Solution to a steel mill problem

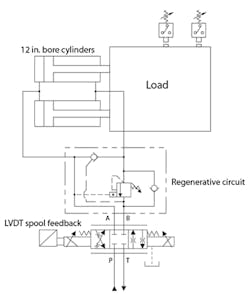

Last month’s issue highlighted problems at a steel mill. After an update, the mill was seeing bumps and jolts during positioning of polishing heads. Replacing a proportional valve did not help. And an electrical engineer found that the electrical signal to the valve was clean and consistent in both increasing and decreasing modes.

To solve the problem, the maintenance department called in an outside hydraulic service shop for help. Dan Turner, of Turner Hydraulics, Carlisle Pa., examined the control and hydraulic system and felt the problem was probably the deadband of the proportional pressure and relieving valve. When the spool is controlling pressure, it acts as a modulating flow control. However, when it needs to reduce the flow faster than the built-in bleed off, the spool moves to completely block off the supply and open the outlet to the relieving port.

This type of pressure relieving valve normally has a spool with the same deadband characteristics as a standard directional valve spool. Turner found the valve to be a Sun Hydraulics PRDP type and confirmed this deadband construction. (Sun calls it their closed-center version.) He also found that Sun Hydraulics makes a PRDL model, what they call an open-transition version that has a more dynamic and bumpless transition between reducing and relieving modes. It also fits in the same cavity as the original valve.

The mill installed the new PRDL valve, which solved the problem.