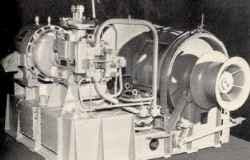

This winch, one of 56 installed on two refrigeration ships, will handle loads as follows: a. 11,000 lb at 160 fpm, b. 7400 lb at 220 fpm, c. 0 to 1850 lb at 400 fpm.

Reducing cargo loading and unloading times is critical in the shipping business. To help stay competitive, ship operators are looking to improve the efficiency of their cargo handling machinery. Oil hydraulic equipment, particularly the highly versatile variable speed hydraulic being used to accomplish this.

Hydraulically operated winches handle loads much faster because they are able to accelerate and decelerate smoothly at a high rate. Useful operating time of the equipment has also increased because of fewer breakdowns and less maintenance. This occurs because the hydraulic drive provides instantaneous overload protection.

Usually, hydraulic winch drives can reduce peak power consumption, aiding in ships where power-generating capacity is limited. This is a result of relatively high efficiency and the ability of these drives to exert extremely high torque at very low output speeds and low input power.

Lake Shore Engineering Co. has built 56 of these typical hydraulic winch drives for installation on two refrigerator ships.