Pneumatic quick-acting couplings provide a fast, convenient way to repeatedly connect and disconnect air lines.

Fig. 1. Ball-lock couplings are the most popular quick-acting coupling in use today and are offered by many manufacturers.

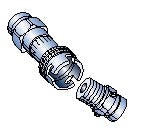

Fig. 2. Roller-lock coupling design positions rollers circumferentially around the ID of the socket to grip the plug.

Fig. 3. Pin-lock couplings use pins arranged in a truncated-cone formation to grip and hold the plug in the socket.

Fig. 4. A twist of the sleeve secures the plug once it has been inserted into the socket of the bayonet-type coupling.

Fig. 5. Ring-lock couplings secure by pushing plug into socket; they disconnect by rotating the socket's outer sleeve.

Fig. 6. Multi-tube connectors quickly connect multiple lines of tubing in a specific orientation.

If a hose or tube in a pneumatic system will be connected and disconnected more frequently than once a week, then chances are a quick-acting coupling will pay for itself rapidly by improving productivity. Although simple in concept, many quick-acting couplings are precisely engineered for specific applications. Their widespread use over many years has yielded a variety of designs.

Regardless of the manufacturer, all quick-acting couplings have some elements in common. All have two parts: a plug and a socket. The plug is the male half and the socket is the female half. When connected properly, these parts seal and lock the joint effectively to contain internal pressures and resist any tensile forces that tend to pull the joint apart. The parts are easily disconnected without tools by disengaging a locking mechanism and separating the parts.

One common application is in assembly workstations, where a worker may have to rapidly switch from impact wrench to drill to riveter. With one quick-acting coupling half on every tool and the mating half on the air line, tool changing is accomplished in seconds. Without the couplings, separate air lines would be needed for each tool; the mass of tools and lines would clutter the workstation and could slow down production.

Basic components

A plug may be one or two-piece construction.

- One piece: A single screw machine part, valved or unvalved, machined to accept the mating locking mechanism of the female or coupler half

- Two piece: Same as one piece except that the screw machine parts are used to make up the complete part. This may be desirable to provide flexibility in providing a variety of end terminations. It may also be used as the retainer for a valve assembly.

- In all cases, the socket is constructed to provide a leak-tight interface with the coupling. This requires:

- A sealing surface to mate with a seal carried in the body.

- A receptacle for the locking mechanism carried in the body.

- An end termination to connect the plug to a hose, tube or port.

A socket may also be a one or two-piece construction.

- One piece: A single part machined to accept the configuration of the mating plug and to provide a leak tight seal

- Two piece: Same as one piece except two parts are used. The second part may be used to retain the valve assembly, and/or to provide flexibility in providing a variety of end configurations

Valve arrangements

Pneumatic systems generally employ a single shutoff valve coupling. In this design, the valved coupling half prevents air loss from the system while the joint is disconnected, and the unvalved coupling half allows downstream air to bleed off. (In hydraulic applications, both coupling halves often are valved, to minimize fluid leakage and limit the amount of air, dirt, and water that can enter the system.)

Coupling types

Ball-lock, Figure 1, is a common design and has a wide range of applications. A group of balls is positioned in holes located around the ID of the socket body. These holes normally are tapered or stepped to reduce their diameter at the socket body ID, so the balls do not fall into the cavity vacated by the plug when the coupling is disconnected.

A spring-loaded sleeve around the socket body's OD forces the balls toward the socket body ID. To connect the plug, the sleeve is pushed back, which opens clearance so the balls are free to move outward. Once the plug is in place, releasing the sleeve forces the balls inward against a locking groove on the OD of the plug. To disconnect, pushing the sleeve back provides the balls with clearance to move outward and allow the plug to be removed.

Roller-lock couplings, Figure 2, use locking rollers or pins spaced end-to-end in grooves or slots around the socket's ID. As the plug is inserted, a ramp on the plug OD pushes the rollers outward. Once the plug is inserted the prescribed distance, the rollers slip into a retention groove on the plug's OD. Retracting the locking sleeve, which allows the ramp on the plug OD to move the rollers outward, releases the plug.

Pin-lock couplings, Figure 3, allow push-to-connect joining using only one hand because the outer sleeve does not need to be retracted to make a connection. In this design, pins are mounted around the socket body ID in a truncated-cone-shaped formation. Pushing the plug into the socket moves the pins back and outward, due to a ramp on the plug. Shear across pins locks the plug into the socket. Retracting the springloaded sleeve, which forces the pins back out of the locking groove, releases the plug from the socket.

Bayonet couplings, Figure 4, rely on the familiar twist locking arrangement and are widely used in a variety of applications, especially in plastic couplings for lighter-duty pneumatic equipment. To join the coupling halves, lugs on the OD of the plug engage slots in the socket sleeve as the plug is pushed into the socket. A quick turn locks the lugs into position. Turning the plug in the opposite direction allows the halves to be pulled apart.

Ring-lock couplings, Figure 5, use a split ring seated in a groove and slot in the socket. Pushing the plug into position causes a ramp on the plug to spread the ring apart at the split until the ring snaps closed behind a retention shoulder on the plug. Rotating an external sleeve expands the ring, thus releasing it from the retention shoulder so the halves can be pulled apart. This design provides maximum flow in a small envelope for normal shop air applications. A variation of this design uses jaws instead of a split ring to lock the parts together.

Coupling selection

Before selecting a coupling, questions must be answered regarding its expected performance. How often will the coupling be connected and disconnected? What type and diameter of hose or tubing will be used? Will the coupling or hose be subjected to abuse such as impact from falling objects, severe vibration, or contamination from the work environment?

A wide variety of O-ring and seal materials — elastomers, PTFE, etc. — is available. Material chosen for the plug and socket also is important. Steel, stainless steel, brass, and aluminum are common. Lighter and inexpensive couplings made from plastics are much more common in pneumatic use than with hydraulics, due to lower pressures and lower environmental concerns.

While most couplers are brass, most plugs are steel. This is done because the nipple is usually on a tool that gets thrown around — and a brass plug would be damaged more quickly than a steel one.

Pressure rating relates to values that provide optimum service life and maximum pressure that can be tolerated without failure. Manufacturer literature should provide data for both of these ratings of pressure. Information should also help in determining safety factors if service rating may be exceeded.

Literature also should include data for determining pressure drop through the coupling at expected flows and pressures. Many of these calculations are based on flow of water at 60° F. Calculations for air are more complex because a gas's density varies widely with its pressure and temperature. A rule of thumb to estimate maximum air flow at 100 psig inlet and 5-psi pressure drop is to multiply flow coefficient of the coupling by 25. Often, literature contains more detailed data on maximum air flow at prescribed inlet pressures and pressure drop. Therefore, precise values for pressure drop for specific couplings should be obtained from the manufacturer.

Also be aware that couplings may be subjected to pressures well above the maximum operating pressure. Sudden shifting of valves or abrupt application of heavy loads can cause system pressure to quickly rise and fall within milliseconds. These pressure spikes often go undetected in a system, but still can damage seals and locking elements of the coupling. Ultimately, then, the coupling would develop leaks, become difficult to disconnect or reconnect, or any combination of these. To prevent these problems from occurring, select a coupling with a pressure rating substantially higher than the anticipated maximum operating pressure.

Depending on the application, the coupling may be subjected to vibration or relative rotation between the mating halves while pressurized. In most cases, these conditions will shorten the expected life of the coupling by causing leakage or difficulties in connecting or disconnecting. Therefore, check with the manufacturer to determine if the coupling will tolerate these conditions.

Multi-tube connectors

As pneumatic systems become more complex and the trend toward modular automation increases, the need to connect and disconnect the growing number of pressure and control lines grows almost exponentially.

Multi-tube connectors, Figure 6, are the fluid equivalent to electrical Cannon-style connectors. They quickly and easily connect or disconnect several tubing lines, while maintaining a correct line orientation and discrete flow paths during reconnection.

Radial seal multi-connectors use a pin-shaped passage which is inserted into a cavity containing a retained O-ring.

Axial seal style multi-connectors merely mate, instead of sliding into one another.This allows for reduced insertion force, decreased wear, and a smaller overall profile.

Thanks to Charlie Wuollet, pneumatic product engineer, and Scott Letts of Parker Hannifin Corp.'s Quick Coupling Div., Golden Valley, Minn.; and Hansen Coupling Div., Tuthill Corp., Berea, Ohio, for their assistance with this article.