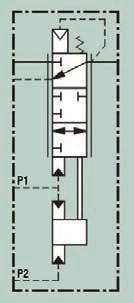

Hydraulic-to-air relay modulation valves are one choice for trailer braking

Farming has changed dramatically from the “good ol’ days.” Family farms are gradually disappearing as corporate farms have become the norm. The way tasks are performed has also changed, as many farmers no longer have to eyeball their work while seeding, spraying, harvesting or cultivating. Instead, tractors are now equipped with GPS and other technologies that make farming more productive and efficient.

Agriculture has charged ahead into the future, yet a fundamental safety issue seems to have been left behind. With all the technological progress that’s been made, thousands of farmers often still find themselves in the precarious position of pulling a heavy trailer with an inadequate braking system or, in many cases, no brakes at all.

Generally speaking, the subject of trailer braking is only considered an issue when high speeds are involved, such as the risk of a semi-tractor trailer jackknifing while hauling a shipment down a highway. However, the potential for an accident exists any time a tow vehicle is not capable of resisting the inertia of a heavy trailer — regardless of the speed, condition of the roadway, or other path of travel. Low-speed tractors towing heavy grain carts or slurry tanks are susceptible to the forces that cause these accidents to occur.

Real numbers on real dangers

Many farmers have adapted to the lack of trailer brakes by coming up with innovative ways of stopping the trailer. One interesting alternative method for trailer “braking” is to just let off the clutch and slow down the tractor while the trailer sinks into the soil. In the case of an emergency stop situation, the operator simply drops the tractor bucket in the hope that the action brings everything to a halt.

Although many farmers can share stories where quick thinking saved the day, the statistics show that danger is not always avoidable. According to the National Institute for Occupational Safety and Health (NIOSH), tractor overturns cause 132 deaths each year. An analysis of NIOSH data between 1992 and 2005 indicates that 1412 farm workers died of tractor overturns. Certainly numerous reasons for all of these overturns exist, but the focus of this article is to shed light on the importance of trailer braking systems in agricultural tractor towing applications.

Government regulations

In the United States, any trailer with a gross vehicle weight rating of 3000 lb or more must have brakes that are adequate to control that trailer’s movement and provide for breakaway braking. The brakes must also be adequate to stop the trailer, hold it, and enable the driver of the towing vehicle to apply the brakes from the cab.

But there is an exception, which applies to vehicles or implements of husbandry. The exception to the 3000-lb rule applies to any vehicle used exclusively for agricultural purposes. These vehicles are not required to have brakes until different criteria are reached — and this secondary set of husbandry guidelines varies from state to state.

Braking in Europe

A different set of standards for trailer braking exists in Europe, where farm tractor travel on highways tends to be much more common than in the U.S. Unlike the vehicles of husbandry exceptions in American guidelines, European regulations generally treat farm vehicles as any other vehicle. As a general rule, some experts simply suggest that any trailer weighing more than five metric tons (11,000 lb) when loaded should have service brakes, parking brakes, and breakaway brakes.

Agricultural tractors in the U.K. cannot legally travel more than 20 mph unless fully suspended and equipped with an anti-lock brake system. However, in actual practice, tractors not meeting those specifications routinely exceed that speed. Therefore, European legislators are beginning to demand higher braking performance from tractors and trailers alike. Specifically, a new regulation in the UK requires 50% brake efficiency on all agricultural trailers manufactured after 2008.

When braking happens

Exploring the basic physics of the conditions typically encountered in trailer braking makes it apparent how dangerous scenarios can arise when attempting to stop. Whether it’s a pick-up truck pulling a boat or a tractor hauling a grain cart, most trailers pivot at a single point at the rear of the towing vehicle. Generally speaking, the single hitch-point design makes a lot of sense for pulling trailers; as long as the towing vehicle is large enough, it can tow anything.

But for trailers without brakes, the single point alignment may allow too much freedom of movement when the towing vehicle attempts to stop. Think about pulling a child’s wagon. Now think about turning around and trying to push that same wagon with the tongue and how difficult it would be to maneuver it.

That’s basically what happens when a non-braking trailer pushes up against a braking tractor. As that pushing force is applied, the trailer’s movement puts downward force on the pivot point where the tractor and trailer are connected. With enough pressure applied to a pivot point on the tractor’s rear, the tractor’s front wheels could be pushed up, creating the potential for a loss of control of both the tractor and trailer. In addition, the inertia of a heavy trailer behind a tractor can simply keep pushing straight, overcoming the tractor.

Managing the physics

Braking requirements can be calculated by a formula that considers speed, mass, rolling radius, and surface conditions. And when you consider that speed exponentially increases the braking force needed, you can understand that higher speeds require much higher braking force regardless of the combined mass of the vehicles.

By far, the easiest and safest way to control a trailer’s stop is with appropriately sized trailer brakes. It’s a simple concept, but one worth repeating — if a trailer is not equipped with brakes, its inertia will keep it moving faster than the vehicle that is braking. By having the trailer brakes enabled at the same time the tractor∏s brakes are applied, the trailer can match the speed of the tractor, and they will slow down together. This eliminates the pushing effect from the trailer on the tractor and allows the trailer to maintain multiple friction contact points with the ground, rather than on a single pivot point with the towing vehicle.

Trailer braking methods

Although the concept of slowing a tractor and trailer at the same time to the same speed seems simple enough, challenges can arise in synchronizing the two. For tractors with hydraulic brakes, hydraulic modulation provides a solution. This method simply takes a hydraulic feed from the tractor's standard two-line hydraulic system and routes flow directly to the trailer to actuate its hydraulic brakes.

Another solution is electric brakes, in which a driver modulates the electrical power going to the trailer's braking system. However, this method makes it difficult to find a balance where the trailer and towing vehicle each take on their fair share of braking force. The trailer may be doing the bulk of the pulling, or the tractor may do most of the braking. Although it is preferable for the trailer to pull on the tractor, this scenario accelerates wear of the trailer's braking system. Attempts at finding a balance often produce jerky travel.

Another alternative is air brakes. In fact, some tractor manufacturers want to standardize trailer brake output using compressed air. Air outputs are standard in Europe, and this method makes significant technical and economic sense. However, an air brake system needs large tanks and other components to actuate the disc or drum brakes on the trailer. This significantly reduces the power-to-space ratio and increases trailer weight. Moreover, size limitations on trailers or axles may even prohibit the use of a large air brake system.

If manufacturers do standardize on air brakes for trailers, a tractor’s hydraulic system could control trailer braking by using a hydraulic-to-air relay modulation valve. The valve works by sensing the incoming hydraulic pressure when an operator presses on the tractor’s brake pedal. This pressure is then converted to a regulated air pressure that is transmitted to the trailer’s air brake system. This allows a tractor’s compressed air system to modulate air pressure to the trailer.

Just as a hydraulic signal can be converted to air, component manufacturers have developed actuation devices to convert an air signal to hydraulic in instances where hydraulic brakes may offer a better braking solution for a trailer.

It’s about safety

Farmers will encounter several situations where trailer brakes will not be a necessity. But to ensure the safety of everyone involved in a farming operation, it’s important to have a healthy respect for the physics involved in bringing heavy machinery to a safe stop. Give careful thought to the situations equipment may encounter to determine appropriate braking needs.

Implementing any trailer braking system cannot guarantee eliminating all trailer-related accidents. But it’s a step toward a safer work environment so that everyone — from the family farmer, to the 60,000- acre corporate manager, to the hired hand — will appreciate every day they get home safe and sound.

For more information on trailer braking options from Mico, visit www.mico.com.

This article appeared in the June 2011 issue as "Braking physics with trailers"