Poor plumbing practices can permanently cripple a fluid power circuit even if it was designed with the best engineering practices and assembled with the most up-to-date components. Undersized lines, elbows instead of bends, incorrect component placement, and long piping runs are a few of the items that strangle fluid flow.

Other problems, such as using tapered pipe threads or lines with thin walls, can make a circuit a maintenance nightmare that requires daily attention. Fortunately, there are numerous publications that assist in specifying correct line size and conductor thickness to give low pressure drop and safe working-pressure limits.

Because pneumatic circuits are less complicated and operate at lower pressures than hydraulic systems do, they are not as vulnerable to plumbing problems. One very important aspect that often is overlooked is the length and size of lines between the valves and actuators. Piping between the valve and actuator should be as short as possible and of the minimum diameter to carry the required flow. The reason for this is that all the air in the pipes between the actuator and valve is wasted every cycle. These runs must be filled to make the device move but the air it takes to fill them does no work. During each cycle, air in the actuator lines exhausts to atmosphere without helping cycle time or force. For this reason, always mount the valve close to the actuator ports.

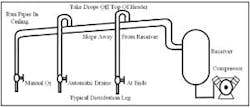

Another aspect of plumbing a pneumatic system is the in-plant pipe installation procedure. To get the required amount of compressed air to the point of usage requires some planning — or the site may be starved at times.

Pipe materials and size: Air systems are normally plumbed with Schedule 40 black iron pipe. (Galvanized pipe is not recommended because some galvanizing material may flake off and get into moving parts.) Several other available plumbing materials could be used for air piping because pressure is relatively low. Some mechanics recommend plastic pipe, but be aware a few synthetic compressor lubricants attack plastic and cause it to lose strength. This type of damage weakens the plastic until it can burst, sending shards of plastic flying everywhere in the plant. Never use any piping material not specifically designated by code.

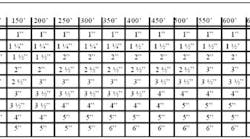

To help select pipe size, the chart in Figure 3-1 shows flow (in cfm) down the left-hand side, length of run (in feet) across the top, and minimum Schedule 40 pipe size in the body at the intersection of these two.

This chart is based on a 1-psi pressure drop for the run lengths given. The right-hand column shows approximate compressor horsepower for the flow figures on the left. Using larger than specified pipe is of little help in reducing pressure drop, but provides more storage volume to handle short brief-flow needs. This chart does not consider fittings and valves, but they also must be considered when figuring the length of a run. Add 5 to 7 ft of pipe length for each fitting or valve — to be on the safe side.

Not having enough air to run the equipment is expensive, so never try to save a few cents at installation by skimping on pipe size. One or two pipe sizes over minimum add little to cost up front, but can make a big difference later. It is less expensive to run oversize pipe initially than to have to add a line later.

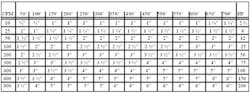

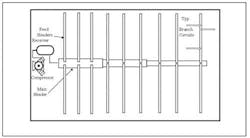

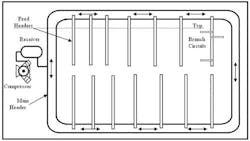

There are three basic compressed-air piping layouts that meet the requirements of most industrial plants. Some facilities may have two or more of these systems to handle special needs. In general, smaller plants use a modified grid system, especially when the facility is growing. A unit distribution system offers flexibility, but can be expensive up front. A loop system is best suited to new construction; it provides extra storage capacity and dual supply for short bursts of high flow.

Figure 3-2 shows a typical grid-system layout using a centrally located air compressor. All air from the receiver goes to a large header pipe that runs down the center of the plant or department. Branch lines from the header go to separate areas where working drops come down to specific machines. With preplanning for future working drops, this arrangement is very flexible.

Machines can be plumbed with any of the materials recommended for plant piping. However, because piping at the machine is usually much smaller, polyethylene, nylon, or vinyl tubing with push-to-connect fittings will work very well. Such tubing and fittings come in a variety of sizes (and colors) and require only a few tools to install. The push-to-connect fittings also release easily for troubleshooting checks or rework.

Pipe materials and sizes

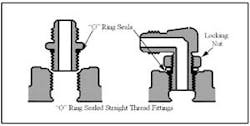

Though many hydraulic circuits are plumbed using black-iron pipe with tapered pipe threads, this is not the recommended way. It is nearly impossible to maintain leak-free operation of a 1000- to 3000-psi hydraulic system for any period of time with tapered pipe threads. Even if pipe-connection compound is used, expansion and shock soon loosen the taper interference and fluid weeps through the resulting openings. Another problem with tapered pipe threads occurs on circuits that must be routinely dismantled. Every time a tapered pipe thread is unscrewed, it must be tightened past where it was originally to get a good seal at reassembly. This can only happen so often before the pipe and/or valve must be replaced.

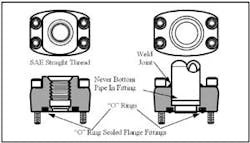

The recommended plumbing material is steel tubing with straight-thread O-ring fittings up to 2-in. OD, Figure 3-6. In sizes larger than 2 in., use steel pipe with welded SAE O-ring-sealed flange fittings on each end, Figure 3-7. For flexible connections, reinforced rubber hose is most common; however, some prefer sealed steel swivel joints.

A good reason for using steel tubing is that it is easily formed to allow for direction changes. Instead of installing fittings that can cause turbulence, use a tube bender to make sweeping turns that eliminate most of the pressure drop associated with elbows. This produces less pressure drop and less heat. Tubing is designated by its outside diameter (OD). As wall thickness increases, inside diameter (ID) decreases. (Black-iron pipe is measured by its nominal ID, but also has a decrease in ID with increase in wall thickness.)

Hydraulic hose

There are places on many machines where rigid pipe or tubing cannot be used because of their inflexibility. Rigid lines can cause problems at cylinders with pivot mountings, pumps on noise-isolation mounts, or connections between separate units. Hose avoids these problems.

However, wholesale use of hose in place of rigid lines it is not generally recommended. Hose is expensive, must be replaced on a regular basis, and flexes and stretches under pressure surges. This flexing produces extra volume and adds to cycle time. It is never recommended to use hose in a servo circuit (although there are times it can't be avoided). Servo circuits are for actuators that need precise control and flexing of hose lines can cause these valves to respond slowly and then go into high frequency oscillations.

Hose is specified by its inside diameter (ID) and, unlike pipe and tube, this dimension does not change. Thicker walls for higher pressures make the outside diameter (OD) of hose greater. Pressure is specified in working and burst values (similar to pipe). Working pressure should always be equal to or higher than maximum system operating pressure. Flow rates of hose are slightly higher than pipe and about the same as steel tubing due to hose's smooth bore. However, many of the end connectors for hose are restrictive because they always go inside the inner liner. These fittings are only short restrictions, but can raise pressure drop noticeably in some cases.

Several factors influence hose service life and each one is controllable by some up-front fact finding and planning.

1. Never go under the manufacturers recommendation for minimum bend radius. Bending hose always causes stress but flexibility is the main reason for using it. Standard hose construction entails wire- or fiber-braided material laid down when the product is straight. Bending these braided materials puts extra stress on the outside of the bend and bunches up those on the inside. Add the constant expansion and contraction from pressure fluctuations during operation and it is easy to see the adverse effect.

2. Don't use hose above its rated working pressure. While maximum pressure might be set at or below the hose rating, higher shock pressures could be damaging during every cycle. Make sure the pressure rating of the hose on all machines is at or above operating pressure — and design out system shock to protect the hose and other hydraulic components.

3. void operating at temperatures above the rating of the hose. Most hose manufacturers make hoses in different temperature ratings. Of course, the higher the temperature rating, the more expensive the hose is, but it is false economy to use the wrong hose to save a few pennies.

4. Don't install hose where it must twist during each cycle or make it operate in a twist because of poor tightening procedures. Always hold the hose straight while tightening a connection. Either case stresses the hose and causes premature failure and its accompanying extra expense.

Hose distributors know of these pitfalls and can help with installation suggestions, as well as troubleshooting hose problems. The causes of hose problems are usually quite evident to someone who works regularly with hose, even when all he or she sees is the damaged part.

Sizing hydraulic lines

Fluid flow is measured in feet per second (fps), so the type of conduit is irrelevant. Many books have charts that relate gpm to fps for all standard piping systems. Use these charts to pick out the correct size fluid carrier for the required flow.

Pump inlet line (suction line) — Fluid velocity should not exceed 2 to 4 ft/sec (fps). The reason for this recommendation is that the highest possible pressure drop in the pump inlet line is one atmosphere. Actually, no type of hydraulic pump can even come close to this, so most inlet lines never see much more than 3- to 4-psi vacuum. Using velocity higher than 2 to 4 fps dramatically increases pressure — causing cavitation and pump damage. It is best to use a suction line equal to or larger than the size of the pump inlet being plumbed. There are circumstances when a smaller suction line is satisfactory, but only do this when absolutely necessary and with the supplier's approval.

The suction line should be full size; as straight as possible; have no or the minimum number of fittings; never include a standard pipe union; and be completely sealed. Using hose in place of pipe or tube can overcome many possible suction-line problems. Hose is a viable alternative and is quite satisfactory if certain precautions are addressed. Always use hose designed and specified for suction (vacuum) use. Hose normally used for pressure may be rated at 3000 psi but is not suited for suction lines. The reason for this is pressure hose uses an inner lining like a tube in a tube-type tire. The outer layers are strong but they are porous and would leak high-pressure fluid except for the inner tube. High-pressure hose as a suction line sees constant negative pressure trying to collapse the inner tube. After some time, it is possible for the inner liner to be drawn in, restricting flow and causing pump cavitation. This phenomenon may not happen immediately, but usually does cause problems in time.

Return lines — Fluid velocity in return lines should be held between 10 and 15 fps. The pump can push oil returning to tank, but any backpressure in these lines must be overcome by extra pressure at the pump outlet. To maintain a high-efficiency circuit, it is important to keep pressure drop in all lines as low as possible. All energy used to push oil through the lines is wasted and converts to heat.

Working-pressure lines — Medium pressure lines (up to 2000 psi) should not exceed 15 to 20 fps. Flow in systems that operate above 2000 psi can go as high as 30 fps. Unlike air systems, there is usually excess pressure capacity in hydraulic circuits when actuators are in motion. Typically, high pressure only comes into play when the actuators near the end of stroke. In an effort to keep line and valve sizes small, it is common practice to use these higher velocities — but keep in mind this practice wastes energy.

Many fluid power handbooks are available with charts showing tubing and pipe in all different wall thickness, along with flow in gallons per minute (gpm) for all standard sizes. Remember each fitting or valve in the circuit has its own pressure-drop adders, and they must be considered part of the overall pressure-loss picture.