For long service life, safety reasons, and reliable operation of hydraulic circuits, it is very important to use the correct fluid for the application. The most common fluid is based on mineral oil, but some systems require fire resistance because of their proximity to a heat source or other fire hazard. (Water is also making its return to some hydraulic systems because it is inexpensive, fireproof, and does not harm the environment.

Transmit energy.

The main purpose of the fluid in any system is to transmit energy. Electric, internal combustion, steam powered, or other prime movers drive a pump that sends oil through lines to valves that control actuators. The fluid in these lines must transmit the prime movers energy to the actuator so it can perform work. The fluid must flow easily to reduce power losses and make the circuit respond quickly.

Lubricate.

In most hydraulic systems, the fluid must have good lubrication qualities. Pumps, motors, and cylinders need ample lubrication to make them efficient and extend their service life. Mineral oils with anti-wear additives work well and are available from most suppliers. Some fluids may need special considerations in component design to overcome their lack of lubricity.

Seal.

Fluid thickness can be important also because one of its requirements is for sealing. Almost all pumps and many valves have metal to metal sealing fits that have minimal clearance but can leak at elevated pressures. Thin watery fluid can flow through these clearances, reducing efficiency and eroding the mating surfaces. Thicker fluids keep leakage to a minimum and efficiency high.

There are several areas that apply to specifying fluids for a hydraulic circuit. Viscosity is the measure of the fluids thickness. Hydraulic oils thickness is specified by a SUS or SSU designation, similar to the SAE designation used for automotive fluids. SUS stands for Saybolt Universal Seconds (or as some put it, Saybolt Seconds Universal). It is a measuring system set up by a man named Saybolt. Simply stated, the system takes a sample of fluid, heats it to 100° F, and them measures how much fluid passes through a specific orifice in a certain number of seconds.

Viscosity is most important as it applies to pumps. Most manufacturers specify viscosity limits for their pumps and it is best to stay within the limits they suggest. The prime reason for specifying a maximum viscosity is that pressure drop in the pump suction line typically is low and if the oil is too thick, the pump will be damaged due to cavitation. A pump can move fluid of any viscosity if the inlet is amply supplied. On the other end, if fluids are too thin, pump bypass wastes energy and generates extra heat. All other components in the circuit could operate on any viscosity fluid because they only use what is fed to them. However, thicker fluids waste energy because they are hard to move. Thin fluids waste energy because they allow too much bypass.

Viscosity index (or VI) is a measure of viscosity change from one temperature to another. It is common knowledge that heating any oil makes it thinner. A normal industrial hydraulic circuit runs at temperatures between 100° and 130° F. Cold starts could be as low as 40° to 50° F. Using an oil with a low VI number might start well but wind up with excessive leakage and wear or cause cavitation damage at startup and run well at temperature. Most industrial hydraulic oils run in the 90- to 105-VI range and are satisfactory for most applications.

Pour point is the lowest temperature at which a fluid still flows. It should be at least lower than the lowest temperature to which the system will be exposed so the pump can always have some lubrication. Consider installing a reservoir heater and a circulation loop on circuits that start or operate below 60° F.

Refined mineral oil does not have enough lubricating qualities to meet the needs of modern day hydraulic systems. Several lubricity additives to enhance that property are added to mineral oil as a specific manufacturers package. These additives are formulated to work together and should not be mixed with others additives because some components may be incompatible.

Refined mineral oil also is very much affected by temperature change. In its raw state it not only has low lubricity but also would thin out noticeably with only a small increase in temperature. Viscosity modifiers enhance the oils ability to remain at a workable viscosity through a broad temperature range.

There are several causes of hydraulic oil oxidation. These include contamination, air, and heat. The interaction of these outside influences cause sludge and acids to form. Oxidation inhibitors slow or stop the fluids degradation and allow it to perform as intended.

Wear inhibitors are additives that bond with metal parts inside a hydraulic system and leave a thin film that reduces metal-to-metal contact. When these additives are working, they extend part life by reducing wear.

In most hydraulic systems, fast and turbulent fluid flow can lead to foaming. Anti-foaming agents make the fluid less likely to form bubbles and allow those that do form to dissipate more rapidly.

Moisture in the air can condense in a hydraulic reservoir and mix with the fluid. Rust inhibitors negate the effect of this unwanted water and protect the surfaces of the systems metal components. All of these additives are necessary to extend system life and improve reliability.

Overheating the fluid can counteract the additives and decrease system efficiency. Overheating also thins the oil and reduces efficiency because of internal bypassing. Clearances in pump and valve spools let fluid pass as pressure increases, causing more heating until the fluid breaks down. External leaks through fittings and seals also increase as fluid temperatures rise. Another problem caused by overheating is a breakdown of some seal materials. Most rubber compounds are cured by controlled heat over a specific period of time. Continued heating inside the hydraulic system over long periods keeps the curing process going until the seals lose their resiliency and their ability to seal. It is best if hydraulic oil never exceeds 130° F for any extended period. Installing heat exchangers is the most common cure for overheating but designing heat out of a circuit is the better way.

Cold oil is not a problem as far as the oil is concerned but cooling does increase viscosity. When viscosity gets too high, it can cause a pump to cavitate and damage itself internally. Thermostatically controlled reservoir heaters easily eliminate this problem in most cases.

Fire-resistant fluids

Certain applications must operate near a heat source with elevated temperatures or even open flames or electrical heating units. Mineral oil is very flammable. It not only catches fire easily but will continue to burn even after removing the heat source. This fire hazard situation can be eliminated by several different choices of fluids. These fluids are not fireproof, only fire-resistant, which means they will burn if heated past a certain temperature but they will not continue to burn after removing them from the heat source.

Generally, the fire-resistant fluids do not have the same specifications as mineral oil-based fluids. Pumps often must be down rated because the fluids lubricity or specific gravity is different and would shorten the pumps service life drastically at elevated pressures or high rotary speeds. Some fire-resistant fluids are not compatible with standard seal materials so seals must be changed. Always check with the pump manufacturer and fluid supplier before using or changing to a fire-resistant fluid.

Water

Originally, hydraulic circuits used water to transmit energy (hence the word hydraulics). The main problem with water-filled circuits was either low-pressure operation or very expensive pumps and valves to operate with this low viscosity fluid above 500 to 600 psi. When huge oil deposits were discovered, mineral oil replaced water because of its additional benefits. Water made a brief comeback during an oil shortage crisis but quickly succumbed when oil flowed freely again.

In the late 90s, water again made inroads into oil-hydraulic systems. Several companies have developed reliable pumps and valves for water that operate at 1500 to 2000 psi. There are still limitations (such as freezing) to using water, but in certain applications it has many benefits. One big advantage is that there are fewer environmental problems during operation or in disposing of the fluid. Price also is a factor because water costs so little and is readily available almost anywhere.

Some suppliers are making equipment that operates on seawater to eliminate possible contamination of the earths potable water sources. These systems operate at elevated pressures without performance loss.

High water-content fluids

Some types of manufacturing still use water as a base and add some soluble oil for lubrication. This type of fluid is known as high water-content fluid (or HWCF). The common mixture is 95% water and 5% soluble oil. This mixture takes care of most of the lubricity problems but does not address low viscosity concerns. Therefore, systems using HWCF still need expensive pumps and valves to make them efficient and extend their life.

Rolling mills and other applications with molten metals are one area where HWCF is prevalent. Often the soluble oil is the same compound used for coolant in the metal-rolling process. This eliminates concerns about cross-contamination of fluids and the problems it can cause.

Water-in-oil emulsions

Some systems use around 40% water for fire resistance and 60% oil for lubrication and viscosity considerations. Again, these are not common fluids because they require special oil and continuous maintenance to keep them mixed well and their ratio within limits. Most manufacturers do not want the problems associated with water-in-oil emulsions so their use is very limited.

Water glycol

A very common fire-resistant fluid is water glycol. This fluid uses water for fire resistance and a product like ethylene glycol (permanent anti-freeze) for lubricity, along with thickeners to enhance viscosity. Ethylene glycol will burn, but the energy it takes to vaporize the water present quickly quells the fire once it leaves the heat source. This means a fire would not spread to other parts of the plant. Always remember fire-resistant not fireproof.

Water glycol fluids are heavier than mineral oil and do not have its lubricating qualities, so most pump manufacturers specify reduced rpm and lower operating pressures for water glycol. In addition, the water in this fluid can evaporate, especially at elevated temperatures, so it must be tested regularly for the correct mixture.

Cost is also a consideration. Water glycol is more expensive than oil and requires most of the same considerations when disposing of it.

Always check with the pump manufacturer before specifying water glycol fluid to see what changes are necessary to run the pump with this fluid. Seal compatibility is usually not a problem, but always check each manufacturers specifications before implementing this fluid. In addition, it is imperative to completely flush a system of any other fluids before refilling with water glycol.

Synthetics

The other main fire-resistant fluids are synthetic types. They are made from mineral oil, but have been processed and contain additives to obtain a much higher flash point. It takes more heat to start them burning but there is not enough volatile materials in them to sustain burning. These fluids may catch fire from a pot of hot metal but quickly self-extinguish after leaving the heat source.

Synthetic fluids retain most of the qualities of the mineral oil from which they are derived, so most hydraulic components specify no operating restrictions. However, most of these fluids are not compatible with common seal materials so seal specification changes are usually necessary. Special consideration must be given to handling of synthetics because they can cause skin irritation and other health hazards. Also most synthetic fluids require protective epoxy paint for all components in contact with them.

Of all the fluids discussed, synthetics are the most expensive. They can cost up to five times more than mineral oil.

No matter which fluid is chosen, design the circuit to work in a reasonable temperature range; install good filters and maintain them; and check the fluids regularly to see if they are within specification limits.

A good operating temperature range is between 70° and 130° F with the optimum being around 110° F. A rule of thumb would be: warm enough to feel hot to the touch but cool enough to hold tightly for an extended period. Overheating hydraulic fluids is second only to contamination when it comes to reasons for fluid failure.

Continuous filtration of any hydraulic system is necessary for long component life. Fluids seldom wear out but they can become so contaminated that the parts they drive can fail. (The filter section of this book offers some good recommendations on keeping fluid clean.)

Even with the best of care, any hydraulic fluid should be checked at least twice a year. Systems located in dirty atmospheres may need to be checked more often to see if a pattern exists that requires special consideration. Pay close attention to the sampling process and packaging procedures recommended by the test facility that will process the sample. Expect a report on the level of contamination plus an analysis of the additive contents, water content, ferrous and non-ferrous material amounts, and any other problem areas the test facility finds. Use this information to know when to change fluids and to check for abnormal part wear problems.

New oil or other fluids from the supplier are not necessarily clean. The fluids are shipped in drums or by bulk, and there is no way of knowing how clean these containers are. Some suppliers offer filtered oil with a guaranteed contamination level at added cost. Otherwise, about the lowest level of contamination from most manufacturers is 25 microns.

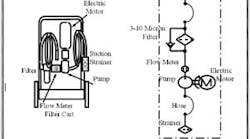

Anytime a system needs new fluid, it is best to use a transfer unit, Figure 2-1, with a 10-micron or finer filter in the loop. Another way of filtering new or refill fluid is with a filter permanently attached to the reservoir, Figure 2-2. In this arrangement, the breather or other possible fill points should be made inaccessible.

The filter cart shown in Figure 2-1 can also be used to filter any hydraulic unit in the plant. Instead of this filter unit sitting idle except when filling systems, set it up at a machines power unit for a timed run. Place the suction hose in one end of the reservoir and the return hose in the opposite end. This adds a continual filtration loop to any machine even when the machines main pump is shut off. Run the cart until the fluid is clean and then move is to another power unit. Repeating this process on a regular schedule can assist the hydraulic units filters and add extra life to the fluid and the hydraulic components. This process may also show a pattern on machines that have a contamination problem.

Hydraulic fluids should be stored in a clean dry atmosphere. Keep all containers closed tightly and reinstall covers on any partially used drums.

Never mix fluids in any hydraulic system. Make sure all containers are clearly marked and segregated so fluids will not be mixed with one another. Mixing fluids can result in damage to components and some combinations are very difficult to clean up. Be especially careful when mineral oils and synthetic or water-glycol fluids are used in different parts of the same plant.

Fluids are the lifeblood of any hydraulic system and should be given the utmost care.