Directional control valves are the most widely used . . . and the least understood . . . valves in fluid power circuits. Many people are confused by the schematic symbol representations, and have difficulty understanding the terms ways, positions, and operators. Learning to read schematic drawings is similar to learning a foreign language. To the trained eye, a symbol speaks volumes even when no words are present. This chapter attempts to take away some of the confusion and apparent magic of fluid power schematic drawings, and thus help make designing and maintaining fluid power systems easier.

Directional control valves can only perform three functions:

- stop or block fluid flow

- allow fluid flow, and

- change direction of fluid flow.

This seems to simplify a seemingly complex subject, but remember, many valves may combine these functions. This makes them a little more complicated, but still not rocket-science material.

Check valves

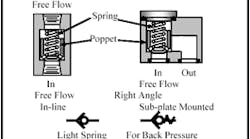

At first glance, the valve type shown in Figure 10-1 does not appear to be a directional control valve. However, check valves do allow flow in one direction and block flow the opposite direction. Use a check valve in any line where back flow cannot be tolerated. Also pilot-operated check valves (discussed in the next section) can be shifted by an external source to allow reverse flow or stop free flow.

The cross-sectional views show the standard poppet design used in most check valves. As in most early designs, the symbol still pictures a ball on a seat. Ball check valves work well until they are disassembled for repair or when troubleshooting. As these valves operate, they wear a groove where the ball contacts the seat. If this wear groove is not reinstalled exactly where it was, the valve is no longer leak free. On the other hand, a guided poppet always goes back in the same relationship to the seat and seals easily after reassembly.

It is easy to understand the function of a check valve. Fluid entering opposite a spring pushes against the poppet and spring to move it out of the way. The inline valve has holes around the angled seat face above the body seat to allow flow to pass. The right-angle design pushes the poppet out of the way and fluid flows by with little restriction.

Check valves are almost trouble-free devices. Seldom is one the cause of a problem. Potential problems can be minimized further if the check valves are: right-angle types, screw-in cartridges, or subplate mounted. Note that an inline check valve’s plumbing must be disassembled before the valve can be checked.

Check valves also can control pressure. Almost all check valves use a spring to return the poppet. In most valves, this spring has very light force, because any spring force results in an energy loss and heat. The light springs from most suppliers require about 5 psi to move the poppet against them (some go as low as 1 psi). Some large check valves, when they are mounted vertically, may require no spring because the weight of the poppet causes it to fall onto its seat.

Strong springs give extra resistance to flow so a check valve could replace a relief valve when low-pressure bypass is required. Many manufacturers have check valves with springs that require as much as 125 psi to push their poppets back. These valves work for low-pressure circuits such as a bypass around a low-pressure filter or heat exchanger, or to maintain minimum pilot pressure for pilot-operated directional control valves. When the spring functions as a backpressure or relief valve, the symbol usually shows the spring as part of the symbol.

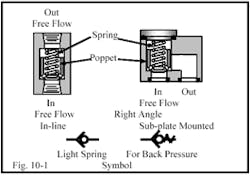

Another lesser-known use for check valves is as a fixed-orifice flow-control function. Figure 10-2 shows an inline check valve with an orifice drilled through the poppet. The orifice allows free flow in one direction and measured flow the opposite way. The orifice is non-adjustable, so this component is tamper proof. The only way to change actuator speed is to physically change the orifice size. This orificed check valve could protect an actuator that might run away if a line broke or a valve malfunctioned. It will not affect speed in the opposite direction. For this application it should be flange fitted or hard piped directly to the actuator port.

Pilot-operated check valves

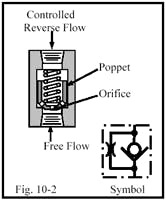

The check valves in Figure 10-3 operate like standard check valves, but can permit reverse flow when required. They are called pilot-to-open check valves because they are normally closed but can be opened for reverse flow by a signal from an external pilot supply.

The first cutaway view of a pilot-to-open check valve in Figure 10-3 is a standard design using a pilot piston with a stem to unseat the check valve poppet for reverse flow. The pilot piston has an area three to four times that of the poppet seat. This produces enough force to open the poppet against backpressure. Some pilot-operated check valves have area ratios up to 100:1, allowing a very low pilot pressure to open the valve against high backpressure.

The second valve in Figure 10-3 shows a pilot-to-open with decompression function. It has a small, inner decompression poppet that allows low pilot pressure to open a small flow passage to reduce backpressure. After releasing high backpressure, the pilot piston can easily open the main poppet for full flow to tank. (This arrangement does not work when the high backpressure is load-induced or generated by other continuous forces.)

The third valve, pilot-operated with external drain, isolates the stem side of the pilot piston from the in free-flow port backpressure that would resist pilot pressure trying to open the poppet. Notice that in the other two cutaway views, any pressure in the in free-flow port pushes against the pilot piston stem side and resists pilot pressure’s attempt to open the poppet. Backpressure could be from a downstream flow control or counterbalance valve in some circuits.

The external-drain port also can be used to make the pilot piston return when using the valve for a pilot-operated 2-way function.

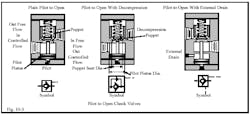

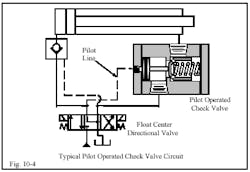

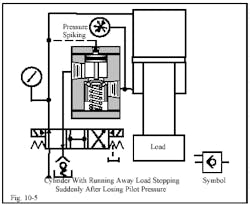

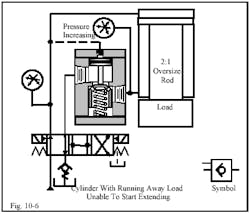

The circuit in Figure 10-4 shows a typical application for pilot-operated check valves. Spool-type directional control valves cannot keep a cylinder from moving from a mid-stroke position for any length of time. All spool valves allow some bypass, so a cylinder with an outside force working against it slowly moves out of position when stopped. Installing pilot-operated check valves in the cylinder lines and connecting the directional valve’s A and B ports to tank in center position assures that the cylinder will stay where it stops (unless the piston seals leak).

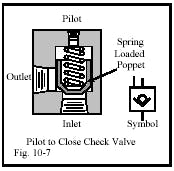

Pilot-to-close check valves

There is also a pilot-to-close check valve, but it is seldom used. It is rarely necessary to have a valve that always stops flow in one direction and also is capable of stopping it the opposite direction.

Notice in the cutaway view in Figure 10-7 that the spring-loaded poppet does not have communicating holes through it to the spring chamber. Flow passes freely from inlet to outlet until a pilot signal is fed to the pilot port. Because the pilot port side of the main-flow poppet has more area than the inlet side, this valve can be closed against free flow.