Compressed air: the hidden utility

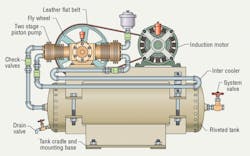

Among the earliest modern lowcost manufacturing machines were compact air compressors and pneumatic tools. An example of an early packaged air compressor is shown in the illustration. These units provided a level of productivity that hand tools couldn’t match, and the use of compressed air exploded, creating the utility industry relies on today.

In most plants, compressed air is a fundamental utility, second only to electricity. If the compressed air system goes down, the plant goes down. In these situations there’s usually a mad dash, with a spare-no-expense attitude, to get rental compressors on site and/or get the primary units up and running. This makes a lot of sense considering that the owners of a plant, which may produce $250,000 of product an hour, don’t want to hear, “We’ll be shut down for two days waiting on a part for the compressor.”

In fact, the compressed air utility is so important that most plants have a completely redundant compressed air system on standby just for these eventualities. In the event of an unscheduled shut down, the backup compressors can be immediately brought on line and carry the plant until the primary units are repaired. In addition to emergency situations, a redundant system is also capable of providing uninterrupted air during routine maintenance periods. In these cases the backup compressors are brought on line and the primary units are shut down so that scheduled maintenance can be properly conducted.

No respect

Unfortunately, many managers and engineering personnel take a rather caviler attitude towards compressed air. It is perceived as a utility, therefor most managers don’t give it a second thought. They regard reliable compressed air in the same way they perceive water, sewer, or electricity — it’s just there. It’s not at all uncommon for those in authority to treat the compressed air system as the ugly stepchild of the capital equipment.

However, this attitude rarely exists on a maintenance level. The maintenance group is keenly aware that this all-important utility is generated on site and they are charged with the responsibility of providing clean, reliable, and uninterrupted compressed air at all times.

The relationship between an uncaring management team and the maintenance group can be frustrating for the mechanics assigned to the compressed air system. They cry out for updated equipment, energy saving systems, and the time to carry out proper maintenance procedures. Yet, in many instances, their pleas fall on deaf ears. Even the most dedicated maintenance personnel eventually give up, and the air system starts a slow decline into decay with disastrous results at the end of the road.

It is essential that management clearly understands the importance of their plant’s compressed air system. Many companies have weekly meetings to discuss various items pertaining to their operations. A brief description on the state of the compressed air system should be included in these meetings and taken seriously. Minor problems in the compressed air system have a way of becoming major — and expensive — problems in a hurry. A healthy relationship between management and the maintenance group can mean the difference between a minor problem and a major production loss.

A plant’s compressed air system can usually be broken up into three basic categories: the compressed air source, the distribution system, and the applications. In order to properly operate and maintain the plant’s compressed air system, management and maintenance personnel should be aware of the various nuances that make up each of these subdivisions.

Verifying compressor output

As most plant and maintenance managers are aware, reliable delivery of compressed air to the plant is critical to its continued operation. Great emphasis is placed on the compressed air system and, in most situations, if a greater demand is placed on the system, key personnel will not hesitate to up-size their compressors. This may seem like a solid, aggressive attitude to take towards the compressed air system, however a little attention to the existing compressors may turn up a common problem that is considerably less costly to deal with.

I have interviewed many plant engineers and maintenance managers over the years who have no idea what their compressor’s actual output is. A compressor that’s been in service for twenty years will typically have a significantly lower output than it had when it was new. Therefore, if you’re planning to purchase a larger compressor, it’s important to know exactly how much compression you’re actually working with. Simply saying “The old unit is a 200-hp compressor, so we should order a 300-hp unit,” won’t do. If the old compressor is significantly worn out, it may be producing much less air than it’s rated for and is actually delivering the equivalent output of a much smaller unit. The real reason that there isn’t enough capacity may be that the compressor is simply not producing like it once was. If this is the case, the best solution may be to rebuild the pump (referred to as the air end) or replace the unit with a new unit of the same horsepower. In either case, this will save a significant amount of money. After all, the cost difference between a 200- and 300-hp compressor is quite significant. In addition to the capital costs, the utility costs for a larger unit can be significantly higher and, when extrapolated over a 20-year period, we’re talking about a lot of money. It’s just not a good idea to jump into something like this without knowing exactly what’s going on with your current system.

As an example, a few years back, I was called out to quote a new 350-hp compressor to replace a 250-hp unit at a large manufacturing facility. As I was talking with the maintenance manager he mentioned that they had gotten the unit from their Canadian branch and it never really worked right. I became immediately suspicious and went to check the motor nameplate, only to find that it was missing. Typical industrial voltage in Canada is 575 V so I started to wonder if this compressor was equipped with a motor that was the wrong voltage for the 480-V drop that the plant had it connected to.

I made a quick check of the output and found that it was producing approximately 60% of its actual capacity. That meant that their 250-hp compressor was only producing 150 hp of air. It’s no wonder they thought it was too small. Personally, I couldn’t understand why the motor hadn’t burned up in the first month of operation. Instead, they just struggled along for two years before they got frustrated and called me. After calling the compressor manufacturer and confirming my suspicions, I recommended replacing the motor with one of the proper voltage and they haven’t had a problem since. By simply spending 15 minutes measuring the output of the compressor, it was determined that the unit could be brought up to specification with a $7500 rewound motor instead a buying a $60,000 compressor, resulting in a savings of $52,500!

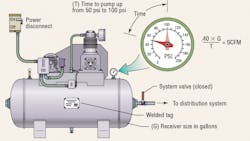

It’s fairly simple to accurately test the output of a compressor with only a few parameters, a stopwatch, and a reasonably accurate pressure gauge. The compressor must feed a receiver or tank of a known volume. The capacity of a compressed air receiver is typically stamped on the welded tag in gallons. The welded tag is typically located on the side of the tank at eye level. The receiver should be equipped with a pressure gauge that is in good condition and has clearly visible graduations. I usually like to use a 4-in. diameter gauge with a 2% accuracy rating. You must know the original factory flow rating of the compressor under test and you’ll need your stopwatch handy.

To conduct the test, close the valve that isolates the receiver from the plant’s distribution system and turn off the compressor. Vent the receiver down to approximately 30 psi and turn the compressor back on. Study the pressure gauge on the receiver and use the stopwatch to time how long it takes for the pressure to build from 50 to 100 psi. Use the following formula to calculate the flow (scfm) of your compressor:

0.45 × VR / t = OC

where:

VR is receiver volume, gal

t is time, minutes

OC is Compressor output, scfm

Dividing the results of the test by the manufacturer’s flow specification will indicate what percentage of the original capacity the compressor is operating at.

As an example, lets say a 712-hp compressor has a factory rating of 28 scfm and an 80-gal receiver. It takes 2 min and 6 sec to build the pressure from 50 to 100 psi. Then:

0.45 × 80 / 2.1 = 17.1 scfm, and

17.1 28 = 0.61

So the compressor is operating at only 61% of its original capacity. This indicates that the compressor is operating at a severely diminished capacity. This information should be carefully considered before replacing the unit. It should be noted that the illustration and example reference a small, packaged compressor; however, this technique is equally appropriate for larger systems with a separate receiver.

About the Author

Leaders relevant to this article: