Sponsored Recommendations

Sponsored Recommendations

May 15, 2024

March 13, 2024

March 13, 2024

March 13, 2024

In order to meet critical operating demands, sealing designers employ a number of materials to best fit the need to contain hydraulic fluid and pneumatic gases and prevent contamination. A material solution often used to tackle severe sealing conditions is the fluoropolymer, polytetrafluoroethylene (PTFE).

Hydraulic and pneumatic seal failures caused by chemical, heat or cold exposure of the seal material and resultant through leakage, can lead to contamination of hydraulic fluid by dirt, metal debris and/or corrosive liquids. Hydraulic equipment that routinely operates at temperature, pressure and chemical environment extremes are subject to accelerated fluid viscosity loss and seal degradation, leading to inadequate lubrication and increased downtime. Misapplication or use of non-compatible materials can accelerate seal failure.Among the popular sealing materials the polymer, polytetrafluoroethylene (i.e. PTFE), has been recognized as an ideal choice for enhancing critical hydraulic and pneumatic equipment performance in demanding applications. PTFE was originally used as a chemically resistant component of nuclear valves and seals. Readily machined, compounded PTFE components are preferred in areas where elastomeric seals cannot meet the frictional, temperature, or chemical resistance requirements of the application. Sealing components in which wide temperature ranges and corrosive environments demand a specific PTFE based solution include:

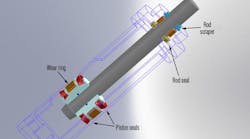

Rod wiper seals— These ensure the rod and cylinder are kept clean and free of foreign matter. The low coefficient of friction, resistance to chemical attack, non-marring surface of PTFE serve this application well.

Bearing guide strips— PTFE wear strips align, stabilize and reduce radial movements of a cylinder’s piston rod from side loading. (Insert “StripBearings.jpg”)

Piston and rod seals— Piston seals from PTFE are designed to prevent fluid from passing over the piston as the system pressure forces the piston through the cylinder bore. Rod seals contain pressurized fluids from leaking out of the system during bi-directional linear motion

Backup rings— Backup rings are typically used to insure a primary elastomeric o-ring or lip seal remains fixed in place during assembly and operation. Generally two backup rings are used per primary seal. For equipment operating at higher temperatures and pressures and in fluid systems, the benefits of PTFE backup rings are valued when long residence times are desired.

Ball valve seat rings— This seal requires the use of materials with chemical resistance, low coefficient of friction, and wide temperature range and is therefore ideally suited for PTFE. Seal engineers design the seat to offset the less desirable properties of PTFE, such as high coefficient of expansion, poor heat transfer and resistance to cold flow.

Machined PTFE based sealing components offer distinct advantageswhen used in place of or in combination with elastomeric and metal sealing components. The following features of PTFE based seals and components highlight the strengths of this material, when compared to other commonly used seal materials, such as metals and rubbers:

Fluid compatibility— As a fluoropolymer, PTFE offers almost complete resistance to all chemical media which allows PTFE to shrug off corrosive environments. Machined PTFE seal components can withstand complete immersion in oil-based or synthetic hydraulic fluids and remain dimensionally stable and readily maintain its mechanical properties. As well, machined PTFE sealing components suffer no deleterious effect (no water absorption, no cracking) when continuously immersed in salt water, chlorinated water or subjected to steam exposure.

High lubricity— Due to the inability of anything to stick to its surface, PTFE based seals offer the lowest dynamic or static coefficient of friction (<0.1) of any plastic, rubber or metal. Its self-lubricating characteristic is well suited to applications in which external lubricants, such as oils and greases can’t be used. If needed, incorporation of molybdenum disulfide (MoS2) and graphite powder can be used to further enhance seal component lubricity by providing a wetted surface, in the case of MoS2, or a dry lubricant additive, in the case of a graphite additive.

Wide working temperature range— Heat degradation is a leading cause of seal failure because it leads to embrittlement in elastomeric seals. Unlike elastomeric sealing components, PTFE offers a very wide working temperature range from a cryogenic to about 480° F. Within this temperature range, PTFE machined components remain flexible, offer excellent damping characteristics and sufficient strength to withstand stretch and pressure. Another important characteristic of machined PTFE components is their complete resistance to UV exposure, which translates to lack of embrittlement even after years of continuous outdoor exposure.

PTFE modifications— To further enhance the sealing properties of machined PTFE, sealing engineers employ components consisting of filled PTFE. Typical fillers used in PTFE compounds, include chopped fiberglass, carbon powder, mica, nickel, bronze and PPS for dimensional stability, resistance to cold flow and higher wear resistance. Through judicious incorporation of molybdenum disulfide (MoS2) and graphite, surface hardness, mechanical strength and wear resistance can be increased and dimensional distortion reduced. For example, a bronze filled PTFE can be used at pressures up to 6000 psi.

Case studies

Bearing guide strips— Bearing guide strips serve an important function in a hydraulic cylinder in aligning, stabilizing and reducing vertical movements of the rod due to transverse loading. Usually two guide strips are installed per piston.In a jack hammer application originally installed with bronze bearing guide strips, premature seal failure occurred as a consequence of heat buildup due to the applications short stroke and rapid action in an abrasive environment. Replacement of the bronze strips with a bronze filled PTFE bearing guide strip provided at least triple the service life, due to improved wear resistance regardless of elevated temperature. From a lubrication point of view, the self-lubricating PTFE guide tape readily exceeds metal-based bearing guide strips by also preventing wear due to metal-to-metal contact. Depending on the application, compounded PTFE wear strips can be produced to specific dimensional requirements and commercially available in continuous or individual lengths.

Energized seals— PTFE bodied seals are composed of a machined PTFE housing, bolstered by a temperature and corrosion resistant energizer, composed of rubber or a compressible metal ring. In addition, the PTFE housing itself can serve as an energizer, eliminating the rubber or metal component. When the seal is installed in the gland, the compressed energizer applies force on the sealing surfaces, creating a tight barrier to prevent gas or fluid leakage. The continuous force of the energizer provides resiliency to compensate for seal wear, gland misalignment or eccentricity. While energizer force provides adequate force for sealing at low pressure, at high pressure the system pressure reinforces the energizer force, resulting in an even tighter seal. In a Bauxite mine, a fast stroke hydraulic system on a rock crusher, was failing due to contamination of the hydraulic fluid caused by wear and of its HNBR elastomer piston seal. Able to withstand the abrasive wear and higher temperatures associated with the dynamic friction, replacement with self-energized PTFE bodied seal eliminated the frequent replacement of HNBR based seals

Failures caused by improper material selection are very common in the industry today and appear to be related to a lack of awareness and understanding of polymeric properties. To minimize costly down times associated with catastrophic equipment failure, different factors should be considered when selecting the correct PTFE sealing and bearing solutions for demanding hydraulic and pneumatic systems. Such things as physical strength, thermal stability, wear and corrosion resistance are the most sought after characteristics that PTFE has to offer. Although it is not always easy, attention to detail is vital when choosing the optimum sealing material to achieve successful and efficient operations.

John M. Kelly is Engineering Manager at Technetics Group Houston. Al Wiggins is Business Development Specialist for Technetics Group. For more information, click here.