An original-equipment manufacturer of custom automation equipment for the food-processing industry built a large pallet-transfer system to shuttle bins of poultry from a defeathering line to a final processing line. The poultry was placed into bins, 10 at a time, and the bins were stacked 10 high. The 10-high pallet-transfer system consisted of a floor-mounted rack-and-pinion drive system with a gerotor motor driving the pinion to move the pallets. The pallets were then shuttled to one of three locations to be off-loaded for final processing.

The OEM overcame the normal struggle of meeting the cycle time to provide smooth acceleration, deceleration, and positioning of the pallets. The system was tested on the OEM’s shop floor, then installed and commissioned at the poultry plant. Several months of smooth poultry operation ensued.

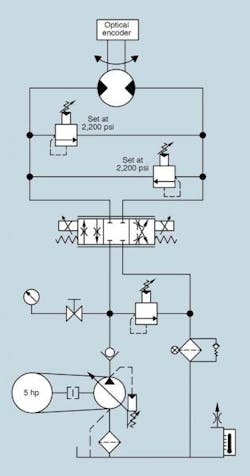

As usual, a call came in for increased cycle time and higher throughput. The bins were modified to accept 15 poultry bodies, and the original pressures on the system were raised to accommodate the 50% increase in load. The system pressure was raised to 1,800 psi and the cross-port reliefs to 2,200 psi. After a couple weeks, the shaft seal on the motor developed a leak. The motor, rated for 2,500 psi, was replaced. However, the new motor also developed a shaft seal leak in short order.

The motors were disassembled, but technicians found no indication of any internal damage. In fact, the motor manufacturer said they looked brand new and that internal components met

factory-new tolerances. With the rack-and-pinion design, side loading seemed to be the only possible cause for the leakage, so an overhung load adapter was installed to eliminate any side load being transmitted to the hydraulic motor’s shaft. This did nothing except allow the leakage to collect between the adapter and motor.

What do think was the problem?

Click here for solution to problem

Solution to Production Boost Causes Seal Leak:

Gerotor style motors generally do not use an external case drain for pressures lower than 1,500 psi or in non-shock loaded applications. otherwise the shaft seals experience short life. CFC's Jon Rhodes had the maintenance crew connect a case drain line from pump to tank, which solved the problem.

We always use a case drain where ever we can, regardless of the operating pressure. Shaft seal leakage is the major reason why gerotor motors are removed from service. One manufacturer claims that installing a case drain on its motors virtually eliminates shaft seal leaks. Case drains are also great to determine if a motor is worn internally by measuring leakage with the motor running at full load.

About the Author

Robert Sheaf

President

Robert J. Sheaf Jr., is the founder and president of CFC Industrial Training, formerly Certified Fluid Consultants, part of CFC-Solar Inc. CFC-Solar provides technical training, consulting, and field services to any industry using fluid power technology.

Leaders relevant to this article: