High-pressure sealing generally refers to confining fluids at pressures above 5,000 psi. Below these pressures, standard energized urethane lip seals and U-cup seals function satisfactorily without special provisions. Above them, some sort of special sealing devices are necessary.

To be effective, seals have to perform three basic functions. They must:

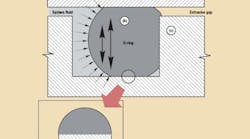

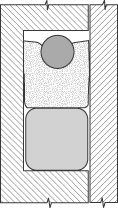

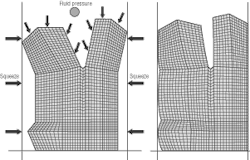

Seal — Sealing elements must conform closely enough to the microscopic irregularities of the mating surfaces (rod to seal groove and/or piston groove to cylinder bore, for example) to prevent pressure fluid penetration or passage, Figure 1.

Adjust to clearance-gap changes — The seal must have sufficient resilience to adjust to changes in the distance between mating surfaces during a cylinder stroke. This clearance gap changes size because of variations in the roundness and diameter of the cylinder parts. The clearance gap also may change size in response to side loads. As the size of the gap changes, the seal must match the size change to maintain compressive sealing force against adjacent mating surfaces.

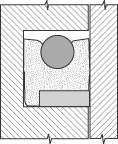

Resist extrusion — The seal must resist shear forces that result from the pressure differential between the pressurized and unpressurized sides of the seal. These shear forces attempt to push the elastomeric seal into the clearance gap between adjacent metal surfaces, Figure 2. The seal must have sufficient strength and stiffness to resist becoming deformed into the gap and damaged or destroyed.

Higher pressure improves sealing

Elastomeric materials also must seal while accommodating dimensional variations caused by manufacturing tolerances, side loads, and cylinder deformations under pressure. Understand that in general, sealing improves as fluid pressures increase. System pressure on the seal surface attempts to compress the seal axially. This compression forces the seal more tightly into the gland and helps improve conformability of the seal with its contacting metal surfaces.

If the clearance gap increases during the stroke, resilience of the compressed elastomeric seal causes it to expand radially and maintain sealing force against the metal surfaces. System pressure combines with seal resilience to increase compressive sealing forces when the clearance gap increases. It generally is true that, as system pressure increases, sealing force and the resulting sealing effectiveness also increase if the seal is correctly designed.

The seal's internal shear stresses increase as system pressure increases. With increasing pressure, the stresses eventually exceed the physical limits of the seal elastomer, and it extrudes into the gap. Difficulties presented by high pressure are not primarily sealing problems but are problems of keeping the seal in its gland while maintaining its structural integrity as increasing system pressures force the seal into the gap.

Almost all of the design and in-service technology of high-pressure sealing deals with protecting the elastomeric seal from the potentially destructive distortion caused by high system pressures. With proper backup to reduce the size of the gap, relatively fragile elastomers can successfully seal extremely high pressures.

When handling a 90-durometer energized urethane lip seal or U-cup at room temperature, the seal seems to be made of an extraordinarily stiff, tenacious material. It requires well-designed experiments and/or sophisticated computer simulations to visualize the state of such a seal inside a hydraulic cylinder at normal operating temperatures and pressures. At pressures as low as 600 psi for 70-durometer nitrile rubber and 1,500 psi for 90-durometer urethane, the seal cross section is significantly deformed. It changes shape almost instantaneously in response to pressure spikes or changes in the size of the clearance gap. Literally, the seal becomes an annular glob in the seal gland.

Seal extrusion

The ability of a seal to resist extrusion into the gap depends on the interaction of:

• system operating pressure,

• system operating temperature,

• size and type of clearance gap,

• seal material, and

• seal design.

System operating temperature is especially important in high-pressure applications because most elastomers soften and lose their ability to resist extrusion at higher temperatures. Some design methods that help lower high system temperatures include the use of low-friction materials, an increase in fluid volume, and a decrease in the cycle rate of the system. However, when ambient temperature is high, and operating conditions are extreme, it is possible for system temperatures to exceed design parameters. Under such conditions, it often becomes necessary to upgrade seals, and for anti-extrusion devices to be more temperature-resistant.

The size of the extrusion gap can be controlled throughout the design and manufacture of the cylinder, piston, rod, and end cap. Decreasing manufacturing tolerances increases cylinder cost, however, and also may increase the probability of metal-to-metal interference. In addition, reducing the extrusion gap size is inherently limited by differential thermal expansion of mating metal components.

The actual size of the extrusion gap is a function of:

• the nominal gap designed into the cylinder,

• manufacturing tolerances, including diametrical variation and ovality,

• diametrical expansion of the cylinder caused by system pressure,

• side loads, and

• wear on radial load-bearing surfaces.

Because all these factors vary, and because the variances can be cumulative, seal design and material must resist extrusion through the largest gap likely to be encountered at design pressure and temperature.

The right material is essential

The key to high-pressure sealing is the use of a material or a combination of materials that has sufficient tear strength, hardness, and modulus to prevent extrusion through the gap. At pressures of 5000 to 7000 psi, the strongest elastomeric materials in standard seal configurations resist the extrusion without reinforcement. At higher pressures, the elastomeric sealing element must be backed by a higher modulus and harder material. Various more-or-less standard backup configurations have demonstrated their effectiveness over many years.

At pressures in excess of 20,000 psi, the extrusion gap must be closed and the elastomeric seal must be protected by a sequence of progressively harder, higher-modulus materials. Properly designed, this progression of materials prevents extrusion, tearing, cutting, or other destructive deformation of the elastomeric seal and distributes loads more uniformly to the element that bridges the gap.

Designs and materials

In high-pressure applications, material characteristics, such as high modulus, tear strength, self-lubrication, and abrasion resistance, become increasingly important. The following seal configurations and materials are specially suited to high-pressure applications. Although these examples cite proprietary compounds as typical, other manufacturers offer their own proprietary compounds, which generally have similar properties.

Abrasion-resistant and self-lubricating materials should be used at high pressures because friction increases there. Some of these materials are:

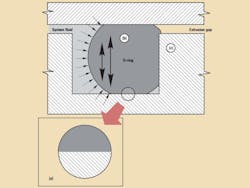

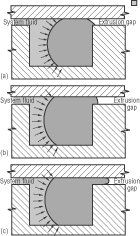

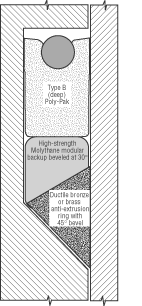

Enhanced polyurethane — At the lower end (5,000 psi) of the high-pressure continuum, a standard PolyPak configuration of modified polyure-thane energized by a resilient O-ring elastomer, Figure 3, is sufficient. Polyurethane-based materials — such as Molythane (impregnated with molybdenum disulfide to provide dry lubrication plus good compatibility with lubricating properties of working fluids) - are suitable for application pressures up to 5,000 psi without backups. Molythane comes in a 90-Shore A durometer formulation for PolyPak seals and in a 65-Shore D durometer formulation with a higher modulus for increased extrusion resistance for anti-extrusion devices. Ultrathane K-24, a high-tensile, reduced-friction, enhanced-urethane material also is suitable for applications to 5,000 psi without reinforcement.

Elastalloy co-polymers — Various elastoplastic or elastalloy copolymers, such as PolyMyte — a material with high tear strength, abrasion resistance, hardness (Shore D 65), and modulus — offer high pressure performance capabilities. PolyMyte configured as PolyPak and energized by a resilient elastomeric O-ring is suitable for applications up to 7,000 psi without backups. A high-durometer PolyMyte modular backup, Figure 4, used in conduction with a Molythane PolyPak, can withstand pressures up to 12,000 psi or more.

Non-elastomeric materials. Non-elastomers include polyamide resins such as nylons and modified nylons and metal backup rings, typically ductile bronze or brass.

One non-elastomer is Nylatron, a glass-filled polyamide resin. A Molythane PolyPak with a positively actuated Nylatron backup ring inserted to bridge the extrusion gap, Figure 5, can be used successful at pressures to 10,000 psi.

For extreme pressures in one direction, a three-part sealing system, Figure 6, is recommended. The seal is made of a Type B PolyPak, backed by a filled-polyamide modular backup beveled at 30°. A wedge-shaped, skive-cut split-ring, machined from ductile bronze or brass, is placed behind the beveled modular backup. The metal backup and seal groove are mated at a 45° angle. Under pressure, the wedge-shaped metal ring expands to close the extrusion gap. This design has operated successfully at pressures to 100,000 psi in a specialized application for making synthetic diamonds.

Compressed by the elastomeric urethane PolyPak, this elastoplastic modular backup expands radially to fill the groove and prevent sealing-element extrusion. Without an additional anti-extrusion device, the elastoplastic modular backup would experience plastic flow into the gap at 100,000 psi. A softer, lower tear-strength urethane back-up element would be nibbled or cut by the metal backup ring especially where the metal ring is split.

These proven designs and materials are typical of those available to increase the pressure capabilities of elastomeric seals in dynamic applications.

Many other materials can be suitable for high-pressure applications. Often, the choice of seal materials is dictated by the fluid medium, system operating temperatures, cost, or system pressure. The potentially higher efficiency of high-pressure systems comes at a slight cost premium. Sealing materials for high pressures are more expensive, and seal designs often are more complicated. Higher sealing pressures increase sealing force and friction. Increased friction causes higher wear rates and may require more frequent seal replacement, but frictional force and wear rates typically increase more slowly than pressure.

Hydraulic system design today often seems to focus on dramatic high-pressure applications. For example, the aerospace industry is presently evaluating 8,000-psi systems for future aircraft in special test beds, such as Lockheed-Georgia's HTTB. Many successful high-pressure systems incorporate innovative seal designs in both static and dynamic modes of operation.

cross-section

Urethane and vegetable oilsThe properties of urethane have made it a popular material for a broad range of hydraulic-sealing applications. However, one negative factor is its susceptibility to hydrolysis. As urethanes are produced, water is the byproduct of the chemical reaction. If water is re-introduced to urethanes later at a temperature high enough (generally 140° F) to cause a second chemical reaction, polymer bonds are broken and the urethane begins to deteriorate. The material hardens and then flakes apart. This phenomenon is known as hydrolysis. If a urethane seal is exposed to ambient water - and particularly hot water or steam - for extended periods, the seal may disintegrate completely. Many vegetable oils have an inherent property of water absorption. If such oils are installed in hydraulic systems, their water component introduces a fluid mixture which jeopardizes seal performance. This phenomenon prohibits the use of conventional urethane seals with vegetable oils (as well as water-based or water-mixed fluids) in common hydraulic applications - which typically run at temperatures high enough to precipitate hydrolysis. |

Low-pressure considerations

Almost every hydraulic system, however, will face occasions when the equipment is not operating, and the pressure falls to zero. Or, in some applications, the system's pressure may never exceed 100 psi. These are typical of the types of operations defined as low pressure; that is, when the confined fluid media exert little or no pressure force on the sealing element to affect or augment a seal.

Within the framework of low-pressure sealing, several primary design considerations affect sealability:

• seal squeeze,

• compression set,

• sealing force,

• gland surface finish conditions, and

• molding flash.

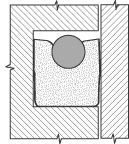

Squeeze

A seal component is generally installed in a groove machined into one of the surfaces to be sealed. As the two surfaces are brought together to form a gland, they squeeze the diametral cross section of the seal. The mechanical squeezing action deforms the seal cross section; the degree of deformation obviously is a function of the squeezing force. In low-pressure applications, the tendency of the squeezed elastomer to maintain its original shape creates a seal. As the elastomer shape is deformed in its gland, it exerts a counteracting (reaction) force against the mating surfaces equal to the force squeezing it, Figure 7, and hence, provides the available sealing force.

Thus, squeeze is a major low-pressure consideration. The recommended squeeze levels are a function of seal cross section, the application conditions and whether the application is dynamic or static.Dynamic compression typically is lower than static compression, due to seal wear and friction considerations. Table 1 summarizes dynamic squeeze levels as defined by MIL-G-5514F — a document that serves as a good guide to those parameters. Static data in the table are summarized from common industrial practice.

Compression set

Compression set reflects the partial loss of memory due to the time effect. In hydraulic systems operating over extreme temperature ranges, it is not uncommon for compression-type seals, such as O-rings, to leak fluid at low pressure because they have deformed permanently or taken a set after used for a period of time. The term compression set refers to the permanent deflection remaining in the seal after complete release of a squeezing load while exposed to a particular temperature level. As related to low-pressure sealing, set-the loss of memory-reduces the compressive sealing force.

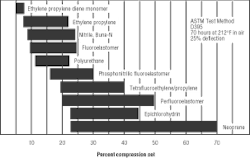

Compression set is expressed as a fraction of the initial squeeze. Thus, a 0% compression set value indicates complete recovery from a compressive load, producing the maximum possible compressive sealing force. A 100% set value indicates no recovery or rebound at all. A seal in this condition will no longer provide a sealing force and hence, has no ability to act as a low-pressure seal. The bar graph in Figure 8 depicts the range of typical compression set values for various sealing elastomers. Of course, compression set properties are a major but not the only factor affecting elastomer choice for low-pressure sealing. Compatibility with various hydraulic fluids must be considered as well.

There are several factors affecting the sealing force:

• material hardness,

• percentage squeeze, and

• seal cross-section size.

For a certain amount of squeeze, the sealing force is directly related to the hardness or elastic moduli of seal materials for low-pressure applications. The harder the material, the larger the initial sealing force. A seal material has a nonlinear stress-strain curve and needs to be described by special material models. For simplicity, linear moduli, such as Young's modulus and shear modulus, are usually used due to their direct relations to the material hardness. The modulus commonly used for specification purpose is tensile stress at a specified elongation. For example, modulus at 100% elongation is the tensile stress corresponding to that elongation.

Hardness generally is measured with a durometer gage - typically using the Shore A scale. The gage measures the force required to deflect the flat surface of a rubber specimen with a pointed indicator. The A scale ranges from 0 to 100; a 90 Shore A compound would be designated as a hard (or high-viscosity) material, and would exhibit much higher compressive force than a 60 Shore A compound, which would be classified as soft.

For a specific material, seal compression force of the elastomeric material increases as the percentage deflection of the seal's diametral cross- section increases. Dynamic squeeze levels typically should be limited to around 12% due to friction and related-wear considerations. Static squeeze levels can be as high as 30%.

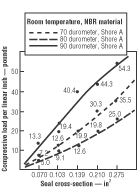

It generally is recommended that a minimum of 0.009-in. squeeze be induced on radial seal cross sections due to compression set considerations. Maximum radial squeeze should be held to 30% because greater squeeze causes assembly difficulties and elastomer deterioration. Compressive sealing load is also directly related to the size of seal's cross-section, Figure 9.

Gland surface finishes

Two physical characteristics of the seal contact-band areas can affect how well the available sealing force is transmitted. These are:

• parting line projection and flash on the seal, and

• sealing surface finishes in the gland.

The finish on machined surfaces that come into contact with the seal is a significant factor in achieving optimum seal performance. Finishes can be defined by different systems, which are often misunderstood and sometimes incorrectly specified in hydraulic design. The American Standard Association provides a set of terms and symbols to define basic surface characteristics, such as profile, roughness, waviness, flaws, and lays.

Roughness is the most commonly specified characteristic and is usually expressed in units of µin. Roughness provides a measure of the deviation of the surface irregularities from an average plane through the surface. In most cases, geometric average roughness or root mean square (RMS) is the preferred method. RMS measurement is sensitive to occasional peaks and valleys over a given sample length.

As related to low-pressure sealing, the sealing element must penetrate these micro imperfections and irregularities in order to block the passage of the fluid media across the contact band area. It is generally accepted and recommended that dynamic interfaces should not exceed RMS values of 16 µin. or 0.4 µm. Static interfaces should not exceed RMS values of 32 µin. or 0.8 µm. Special fluid media would benefit from smoother finishes as listed in Table 2.

Parting line projections and flash

Just as there are irregularities in the form of roughness on the gland surface, there are irregularities or imperfections on the sealing element known as parting line projections and flash. A parting line projection is that continuous ridge of material along the line where the mold halves come together at the ID and/or OD of molded rubber seals, such as O- and T-rings. It results from worn or otherwise enlarged corner radii on the mold edges.

Flash is a thinner, film-like material that extrudes from the parting line projection. It is caused by mold separation when material is introduced or inadequate trimming or buffing after molding. Because flash lines are inevitable in clam-shell-type, compression molding processes, the degree of flash must be controlled. Control is especially critical in low-pressure applications and applications sealing gas-oil interfaces. Standards such as MIL-STD-413E and those in the Rubber Manufacturers Association (RMA) Handbooks provide guidelines on allowable flash criteria for manufacturers and users.

Sealing performance characteristics can be enhanced by eliminating the flash line completely from dynamic and static sealing interfaces. This practice is especially desirable in accumulator applications and those requiring low-viscosity fluid media, such as silicone oils. Manufacturers may offer an optional flash-free seal design for these stringent applications.

Gasket/O-ring-seal combinations

Three primary static sealing methods are in use today. The flat gasket is the oldest of the three. Where reusability is not required and where the possibility of some leakage can be tolerated, the flat gasket may be the best choice. The O-ring represents a marked improvement over the flat gasket for installations where little or no leakage can be tolerated.

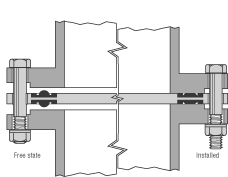

The combination gasket/O-ring seal, Figure 10, represents a significant improvement over both the flat gasket and the O-Ring in a groove for near zero-leakage sealing in static applications. Advantages of the combination gasket/O-ring seal are:

• ease of installation,

• sealing element(s) molded precisely in place,

• limited area of seal exposed to fluid attack,

• visibly inspectable after assembly,

• no re-torquing required,

• high reliability, and

• no special machining of mating flange surface required (no grooves).

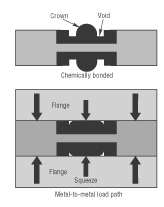

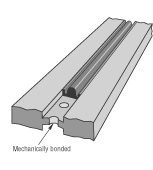

The combination gasket/O-ring seal consists of a retainer plate with a groove in one or both element(s). This seal may be either chemically bonded to the groove or mechanically locked in place by cross-holes in the groove, Figure 11. The combination gasket/O-ring seals are relatively more expensive than O-rings.

FEA-assisted seal design

Vitally important to any method of sealing is the ability of the seal to achieve the proper balance between developing enough elastomer stress to provide an adequate seal and not developing too much stress, which would prematurely degrade the seal. Depending on the type and requirements of the seal, this seal/stress relationship will be different.

The study of elastomer stress and its relationship to seal effectiveness has been dramatically enhanced with the advent of Finite Element Analysis (FEA). FEA is a numerical modeling technique that has been used quite successfully for seal applications. FEA can predict seal deformed shapes and stress distributions after installation, in operation and under various conditions. This information is very important in evaluating the following: stability, sealability, thermal deformation, swelling, and seal life. FEA is becoming a very powerful tool for seal design optimization.

The procedure for FEA-assisted seal design can be summarized as follows:

• seal shape sketch,

• material selection,

• material characterization testing (such as tensile stress strain curve, bulk modulus, thermal constants, friction constants, etc.),

• material model selection (Mooney-Rivlin, Ogden, etc.),

• mesh modeling, boundary condition definition,

• numerical analysis,

• post-processing (output), and

• to see if the seal shape needs to be modified.

Figure 12 shows an example of an FEA plot. FEA is also used for flow and mold analyses, which are desired for elastomer processing control.

(RMS)

(RMS)

molecular gas

fluid and gases

Seal materials

The worldwide industries that design equipment incorporating hydraulic and pneumatic technology have changed considerably over the last 20 years — largely in response to the increased expectations of the end user. From the standpoint of sealing, these expectations now call for effectively leak-free systems, regardless of the application.

Most leading OEMs around the world had once their own acceptability curves which aspiring suppliers had either to meet or beat. Today, however, approval procedures simply state that zero leakage is the standard. Much of the credit for this situation lies with the market perception of quality, which, of course, demands leak-free systems.

Europe in the 1970s responded to the export drives of the large Japanese off-highway equipment manufacturers with tough new quality standards, plus manufacturing, design, and sourcing reviews. One result of these reviews was a move toward higher system pressures to increase machine output. Typical European off-highway equipment now operates between 5,000 and 8,000 psi. Other sectors followed this trend, and today we see 5,000-psi and higher-pressure hydraulic systems in many different industries.

To meet these challenges, leading international seal manufacturers have modified existing materials and developed new ones. These materials enable seals to be made today in virtually any profile and configuration. Modern hydraulic and pneumatic systems commonly use the seal materials listed in the table at right below.

Thermoplastic polyurethanes and polyester elastomers

The greatest strides in seal materials have been made with thermoplastic polyurethanes (TPUs). Initial limitations of the early TPUs have been overcome. Current TPUs can tolerate system operating temperature up to 250°F without suffering serious loss of lip preload and generally do not require O-ring energization. Hydrolysis resistance in some formulations is now so good that TPU seals are used in underground mining cylinders that operate on high-water-based, fire-resistant fluids.

Pneumatic cylinder designers also have benefitted from the advances in TPUmaterials. Calls for very low friction and ultra-long service life have been accommodated by TPU seals which offer 50% of nitrile's breakout friction and have lasted for 12 × 106 cycles in 2-in. bore, 10-in. stroke cylinders with non-lubricated air.

Thermoplastic polyester elastomers (TPE) have also improved. It is possible to chemically engineer TPEs to produce such desirable properties as outstanding wear and fluid resistance. These characteristics have made them a first choice in many sealing applications - particularly as piston seals where, with suitable energization, extremely efficient performance can be produced. Many of these TPE seals compete with PTFE elements where the elastomeric nature of TPE makes them more easy to install and also prevents piston drift. An example is in truck-mounted crane outriggers, where the elastomer can bond into the adjacent surface finish. TPEs with their superior wear resistance and tensile strength are ideal for this use.

In Europe, TPEs have a growing importance in specialty sealing applications such as the mining and steel industries. TPE's heat and fluid resistance perform well in rolling mills, for instance. For port-passing applications, such as phasing cylinders, by exploiting the wear resistance and hardness of TPE, seals can be designed specifically to overcome problems often associated with this type of cylinder design.

The key to success in today's industry for the seal maker lies in combining the latest material technology with innovative profiles to provide the customer with solutions which work.

Future trends

As environmental issues continue to influence almost all industries, the hydraulics sector will be no exception. In Europe and the U.S., so-called environmentally friendly fluids are being developed. Vegetable oils, such as rape and sunflower seed, have been tried, but they can cause problems for the system (forming resin above 180°F) and for the seals and other components (forming acid in any water present that can attack elastomers). Other fluid contenders include polyglycols and synthetic esters, but these also present problems - not the least of which is a cost up to ten times that of mineral oil. New materials and blends will be required to combat the effects of these fluids while still providing the sealing integrity users expect. Preliminary work indicates that there is a long road ahead if this issue becomes a reality.

| Table 3 | |||

| Material | Applications | Positive factors | Precautions |

|---|---|---|---|

| Nitrile | Fluid power cylinders | Inexpensive; good resistance to set | Not tough enough to withstand very smooth surface finishes (<0.4 µin. CLA) |

| Carboxylated nitrile | Better wear resistance than nitrile | Limited low-temperature flexibility, compared with standard nitrile | |

| EPDM | Exposure to fire-resistant fluids | Resistant to HFD fluids and Skydrol | Not resistant to mineral oils, greases, other hydrocarbons |

| Fluoroelastomer | High temperatures (to 400°F) | Resistant to most hydraulic fluids | Relatively expensive and difficult to process |

| PTFE | General sealing | Low friction | Not elastomeric, requires energization |

| Polyurethane | General sealing elements | Good wear resistance and resistance to set; energization not required | First generation subject to hydrolysis effects of water above 120°F |

| Polyester | Rubbing faces of seals; Anti-extrusion elements | Elastomeric; good resistance to wear and fluids | Poor resistance to set; requires energization |

Basic properties of elastomeric seal compoundsAlthough elastomeric compounds used in aerospace seals are derived from relatively few base polymers (such as nitrile, fluoroelastomer, and ethylene propylene), each seal manufacturer usually develops special compounds of these base polymers to enhance or suppress different chemical or physical properties to fit specific requirements of an application. Proprietary formulations of these compounds are kept secret. Even the analysis of a finished elastomer seal presents an incomplete picture of the original elastomer compound because some ingredients are consumed in processing. Of all compound properties, the most critical are the changes that occur. Every property of every compound changes with age, temperature, fluid, pressure, squeeze, and other factors. Standardized tests have been developed to provide comparability in changes among compounds. Compounds with the least tendency to change properties are the easiest to work with; they produce a seal that is adaptable to more applications. The number of properties evaluated for an application depends on the severity of conditions. Factors are highly interdependent, but typically include resilience and memory, abrasion resistance, coefficient of friction, and fluid compatibility. Let's take a closer look at each of these. Resilience and memory are defined as a compound's ability to return to original shape and dimensions after a deforming force is removed. Resilience implies a rapid return, while memory implies a slow return. In seals, resilience is important because it permits a dynamic seal to follow variations in the sealing surface. Although elastomer resilience is frequently measured on a Bashore resiliometer, field experience is required to relate ratings to seal performance. Additional attention is required for low-temperature applications. When temperature is too low, a compound loses its memory. Abrasion resistance — resistance to wear when in contact with a moving surface — is the product of other properties, including resilience, hardness, thermal stability, fluid compatibility, and tear/cut resistance. It also is influenced by the compound's ability to hold a film of protective lubricant on its surface. Harder compounds are usually more resistant to wear, so dynamic seals of 85-durometer compounds are common. However, if the seals encounter high temperatures, it may be good practice to specify an even harder material to compensate for the softening effect of heat. In low-temperature applications, a softer material might be preferred because elastomers tend to harden a temperatures drop. Coefficient of friction (usually only important in dynamic seals) is compound-specific and different for running and break-out. Usually break-out friction is higher. Break-out friction increases with time between cycles. Coefficient of friction is affected by temperature, lubrication, and surface finish. Aging and the influence of service fluids on the compounds may also affect hardness and, in return, both breakout and running friction. As far as fluid compatibility is concerned, a fluid is considered incompatible with a compound if the fluid causes enough property changes to reduce sealing function and/or shorten the working life of the compound. Dissimilar chemical structure is the key to fluid compatibility. For non-polar liquids - such as hydrocarbon fuels and oils - nitriles, fluorocarbons, or fluorosilicone polymers are normally used. For polar liquids, such as phosphate ester hydraulic fluids, ethylene propylene compounds are most satisfactory. |

Dealing with pipe thread fittingsThere is is no question that pipe threads should not be specified in new equipment deisgns. Pipe threads are prone to leakage, especially after being disassembled and reassembled. Furthermore, many more-modern thread forms are widely available that offer long-term, leak-free performance, even after being assembled and reassembled several times. Still, despite their poor perfomrance, pipe threads continue to be used throughout a variety of industries. So accepting that pipe threads will still be encountered, this discussion reviews methods for reducing shortcomings of pipe fittings. Four methods are commonly used to seal pipe threads: Yielding metal. The sealing interface is limited in area and unlimited in force so that yielding takes place. Metal flow fills misalignment and leak paths. These dryseal joints can be effective, but they usually cannot be disassembled and reused without leaking. Trapped dope. The use of drying or non-drying dopes is the oldest and least costly thread-sealing method. Made from ingredients ranging from crushed walnut shells in shellac to other fillers and oils, usually with some thinning volatiles, they are inherently weak, and will shrink when the volatiles evaporate. Trapped elastomer. Confined O-rings can seal effectively, but also can suffer from sloppy assembly. Damaged threads or pinched rings also can contribute to leakage. O-rings typically are used in high-pressure fluid power systems where the extra cost is more easily justified and freedom from contamination is especially desirable. Curing resins. Sometimes called machinery adhesives, these anaerobic acrylic materials develop strength by curing. They are very forgiving of tolerances, tool marks, and slight misalignment. They make tapered fittings as effective as O-rings at a fraction of the cost. They lock free-standing fittings — such as gauges. They can also improve the 98% effectiveness of yielding-metal joints to 100%. The correct grade must be selected because of their wide range of strengths so that disassembly will not be hampered. Curing materials are so effective in sealing threads that they are often used on straight threads that enter or plug pressure vessels. In addition, the curing materials are effective even when tapered threads are lightly torqued. Lightly torqued threads (straight or tapered) do not leave high residual stresses in housings or valves that can distort valve bodies to the point of inoperation or long-term fatigue failure. Probably the most significant event in sealing fittings has been the development of anaerobic pipe sealant with TFE materials. Since the first appearance of these materials, many companies have added anaerobic thread sealants to their lines. The new sealant technology offers a variety of benefits: Convenient curing. Being anaerobic, it cures in the absence of the air, remaining uncured until the parts are assembled. There is no evaporation, hardening beforehand, or other work-life problems. Lubricity. Containing TFE filler, the material eliminates galling or other component-assembly problems. These products prevent over-torquing to affect a seal. Fills threads. Due to high wetting ability, the material fills threads so well that leakage past nicks, scratches, and dents does not occur. Fitting movement. Systems being assembled with anaerobic sealant can be initially readjusted without breaking the seal in the threads. Vibration resistance. Anaerobic sealant does not permit a fitting to be loosened by vibration. Reusability. Fittings sealed with acrylic and latex-based materials can be disassembled and reused with sealant in the field without danger of leakage. Freedom from contamination. Unlike the tape most often replaced by the anaerobic material, sealant does not break up to contaminate lines and valves. A review of the important performance properties of compounds of tetrafluoroethylene (TFE) resin and filler materials shows that the resin performs well in many applications without fillers. In fact, fillers can lessen TFE's outstanding electrical and chemical properties. In mechanical applications, however, compounds of TFE and inorganic fillers offer improved wear resistance, reduced initial deformation and creep, and increased stiffness and thermal conductivity. Hardness is increased, and the coefficient of thermal expansion is decreased. These compounds can make it possible to gain the advantages of TFE in applications where the unfilled resin cannot be used. Many different fillers can be blended with TFE, but most application requirements have been met with five filler materials: glass fiber, carbon, graphite, bronze, and molybdenum disulfide. The properties of any compound depend on filler type and concentration, and processing conditions. Compounds — such as plain TFE — are made into finished parts by molding, extrusion, or machining. One example of the application of TFE resin and fillers is O-rings made of TFE. They are used where resistance to solvents and other chemicals, or extremely high- or low-temperature resistance is required. These are applications where elastomeric materials are not suitable. An additional benefit of TFE O-rings, in certain applications, is the material's low coefficient of friction and anti-stick properties. Typical applications are rotary, piston, and valve seals, and gaskets. |