If you’ve worked with hydraulic equipment for any length of time, it’s likely you’ve come across a hydraulic system with cloudy oil. Oil becomes cloudy when it is contaminated with water above its saturation level. The saturation level is the amount of water that can dissolve in the oil’s molecular chemistry and is typically 200 to 300 ppm at 20°C (68°F) for mineral hydraulic oil.

Cloudy hydraulic oil indicates that a minimum of 200 to 300 ppm of water is present. And the higher the water concentration, the greater the reliability problem. I recently audited a hydraulic system with cloudy oil that was found to contain greater than 1% (10,000 ppm) water!

Water in hydraulic fluid:

• depletes some additives and reacts with others to form corrosive by-products which attack some metals,

• reduces filterability and clogs filters,

• increases air entrainment ability,

• increases the likelihood of cavitation occurring, and

• reduces lubricating film-strength, which leaves critical surfaces vulnerable to corrosion and wear.

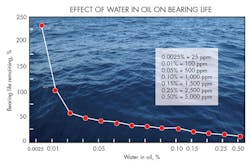

The graph plots bearing life against increasing amounts of water in the oil. As you can see, bearing life is given on the Y axis, and the amount of water in the oil on the X axis. The “reference” bearing life of 100% is based on that which would be achieved with a water concentration of 100 ppm (0.01%). Increasing water content beyond this level reduces bearing life—exponentially at first, then steadily down to around one-tenth at 5,000 ppm (0.5%) water.

Some references cite 1,000 ppm (0.1%) as an acceptable water concentration for hydraulic oil. But as the graph shows, this level of water in the oil reduces expected bearing life to around one third of what it would be if water concentration was controlled at 100 ppm (0.01%). Even at 500 ppm (0.05%) water, bearing life is less than half of what it would be at 100 ppm.

If that’s not convincing enough, water concentration of 500 ppm and above is sufficient to spawn micro-biological contamination (MBC), provided the following conditions also are present:

• Food: Carbon, nitrogen, and phosphorous are readily supplied by the oil.

• Oxygen: Air is typically present in hydraulic oil at 7% to 10% by volume.

• Moderate temperatures: Pptimum bacterial growth occurs at temperatures from 24°C to 49°C (75°F to 120°F).

• Dark, stagnant, or low flow: The hydraulic reservoir provides great breeding grounds.

• Suspended particles: These assist with initial transportation and colonization.

Although all the above conditions are required to sustain bacterial growth, water is the key. So in terms of preventing MBC, keeping the oil dry is vitally important.

Measuring and Removing Water

So how do you know how much water is in your hydraulic oil? The standard laboratory test for accurately quantifying the water content of mineral oils is the Karl Fischer Volumetric Reagent Method, otherwise known as the Karl Fischer test. Fourier transform infrared spectroscopy (FTIR) is sometimes mentioned as a method for measuring water concentration in oil. However, FTIR is only effective for indicating water concentrations greater than 1,000 ppm. This means if you’re serious about monitoring and controlling water concentration at low levels, water content by Karl Fischer must be specified on your oil analysis test slate.

Given the negative effects of water contamination on hydraulic system longevity and reliability, if the oil in your hydraulic machine does contain a high concentration of water, what are your options? In the case of systems with small oil volumes, changing the oil may be the most cost-effective solution. For systems containing larger oil volumes, water removal filters are best suited to removing small amounts of water.

There are two types of water removal filters: coalescing and polymeric. Coalescing filters work by passing the oil through a dense, inorganic fiber mat. The fibers break the oil film, which allows non-emulsified (free) water to adhere to and be retained by the fibers, whereas the oil passes through. As water droplets accumulate in the filter mat, they coalesce into larger droplets; these drain down through the fibers into a collector, which is periodically drained.

Polymeric filters are impregnated with chemicals (polymers) that have a strong affinity for water. They can be absorptive, where free and emulsified water in the oil becomes part of the filter’s chemical structure, or adsorptive, where the water is retained by the element without it becoming part of its chemical structure. Absorptive filters are preferred because they retain the water permanently. Adsorptive filters, on the other hand, have a tendency to release captured water under certain conditions. Polymeric filters are available in similar configurations as particle filters. Note that neither coalescing nor polymeric filters remove dissolved water—water dissolved in the oil’s molecular structure—below its saturation point.

Vacuum distillation uses a combination of heat and vacuum. Water boils at 56°C (133°F) under a partial vacuum of 846 mbar (25 in. Hg). This enables water to be removed at a temperature that does not damage the oil or its additives.

Headspace dehumidification is another technique for lower water concentration in hydraulic oil. It involves circulating and dehumidifying air in the reservoir’s headspace. Water in the oil migrates to the dry air in the headspace and is eventually removed by a dehumidifier. Headspace flush is similar to headspace dehumidification; the difference is that instead of circulating the air in the reservoir headspace through a dehumidifier in a closed-loop circuit, a small (4-5 cfm) flow of very dry compressed air (-40°C dew point) is flushed through the headspace in an open circuit. Here, again, water migrates out of the oil and into the dry air passing through the reservoir headspace.

Another variation of the headspace flush involves installing a hygroscopic breather on the reservoir (one should already be there if you’re serious about controlling water contamination) and connecting a vacuum pump to the headspace. This requires a spare port in the top of the reservoir, ideally as far away from the breather as possible. The beauty of this variation is its simplicity—it doesn’t require a source of clean, dry compressed air.

Exclusion is Cheaper than Removal

Like all other forms of contamination, preventing water ingression is cheaper than removing it from the oil. A major point of water ingression is through the reservoir headspace. Too many hydraulic reservoirs are fitted with breather caps that are not effective in preventing moisture (and particles) from entering the reservoir as the oil volume changes through thermal expansion and contraction, or the actuation of cylinders.

Replacing these inferior breathers with a hygroscopic breather will eliminate the ingression of moisture and particles through the reservoir's vent. These breathers typically combine a woven-polyester media that filters particles as small as 3 µm, with silica gel desiccant to remove water vapor from incoming air. The end result is relative humidity levels within the reservoir headspace that make condensation unlikely, and therefore reduce the ingression of water into the oil.

The Dryer the Better

The key takeaway from all of this? Keep your machine’s hydraulic oil as dry as possible, and ideally below its saturation point. And as is the case with the other two danger contaminants, heat and particles: the lower the number, the better your hydraulic machines’ reliability will be in the long run. Although it may not be appropriate or achievable for every hydraulic machine, water concentration of 100 ppm or less is a good target to aim for.

Brendan Casey is the founder of HydraulicSupermarket.com and the author of The Hydraulic Maintenance Handbook, Insider Secrets to Hydraulics, Preventing Hydraulic Failures, The Hydraulic Troubleshooting Handbook, Hydraulics Made Easy, Advanced Hydraulic Control and The Definitive Guide to Hydraulic Troubleshooting. A hydraulics specialist with an MBA, he has more than 25 years experience in the design, maintenance and repair of mobile and industrial hydraulic equipment.

This file type includes high resolution graphics and schematics when applicable.