Smart Hydraulic Power Units Generate Efficiency and Control

At a Glance:

- Learn what smart hydraulic power pack design looks like.

- Most hydraulic circuits are not a continuously operating system—the energy consumption during idle periods is substantial.

- The use of the VFDs and some additional instrumentation can help save energy and reduce downtime.

Hydraulic power units (HPUs) pressurize oil to power hydraulic equipment. Hydraulic equipment provides higher amounts of force than traditional electrical and mechanical prime movers and can be controlled with more precision. The performance demanded from these hydraulic systems is higher, especially when operating in a 24/7 process industry. Therefore, the operation and maintenance costs—along with the downtime due to breakdown—is a concern for plants and operations that run 24/7.

What is a hydraulic power unit?

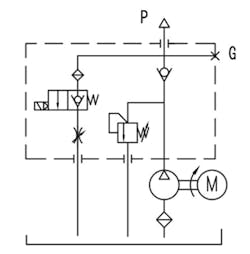

Hydraulic power units are self-contained units that consist of a motor, reservoir, pressure relief valve, filter, pressure gauge, flow meter, heat exchanger, pressure switch, float/level switch, temperature sensor and hydraulic pump. This hydraulic power pack is used for transferring power from one location to another by using hydraulic motors or hydraulic actuators.

How are electrical power and hydraulic power alike?

To draw an analogy, the hydraulic power pack helps develop the pressure in a similar way that electrical voltage is generated by a generator. In other words, a hydraulic power pack is a power generator for a hydraulic system in much the same way that an electrical generator produces potential to transfer power from the generating station to sub-stations for further distribution to our homes.

How does a typical hydraulic power pack function and consume power?

Hydraulic power packs are used in countless applications, from steel mills, galvanizing plants and various steel finishing plants to amusement park and locomotives. The hydraulic power pack is used for transferring power from one location to other by using hydraulic motors. A heater (or a heat exchanger) attached to the power pack helps maintain the oil at designed viscosity.

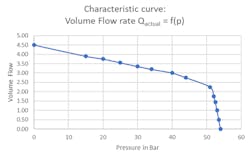

An electric induction motor runs at constant speed to deliver the hydraulic oil at a constant pressure to the hydraulic circuit. The flow meter in the line indicates the flow when the work is being done by the hydraulic oil under pressure. When the work is done, the oil is flowing and the pressure drops (see the plot below).

When the work is completed or is not being done by the hydraulic circuit, the oil is not flowing through the hydraulic system at that time. The pressure in the line increases and, therefore, the pressure relief valve opens to bypass the oil back to the reservoir. The pressure gauge, flow meter and flow switch are all part of important instrumentation that indicate to an operator that the hydraulic pump is maintaining enough pressure, so as to achieve required flow in the hydraulic system.

The systems that run 24/7 in such places as processing plants, hospitals and airports, with HPU AC motors across the line, consume power continuously, even when the hydraulic system is merely pushing the oil through the relief valve rather than doing the real work. In this case, it adds running cost to the energy bills for no work. With VFDs controlling the pressure and the flow in the line, the motor speed can be reduced, hence reducing the pressure to directly impact the energy consumption.

The idea is to reduce the pressure by reducing the pump speed to such a level that the oil does not have enough pressure to be unnecessarily pushed through the relief valve when the system is idling, rather than maintain the pressure to such low levels that it keeps the lines filled, to start pumping as necessary. By reducing the motor speed using a variable frequency drive (VFD), we not only save power but also avoid unnecessary wastage.

We can analyze the power management and the instrumentation components in this typical hydraulic system, along with the opportunities to save on energy and maintenance costs, reduce equipment downtime and deploy predictive maintenance. It can be viewed as an alternate approach to integrating a typical hydraulic power system.

Traditionally, the power management components such as induction motors for hydraulic pumps and heat exchangers are started across the line, causing a lot of wear-and-tear for the motor and equipment.

Because these induction motors are not controlled proportional to flow, pressure or the temperature requirement, once started, AC motors run at a constant speed that leads to unwanted energy consumption during the idle period. Knowing that most hydraulic circuits are not a continuously operating system, the energy consumption during idle periods are substantial. All of the energy consumed by the pump motor and the heat exchanger motor during the idle period can be conserved by using a VFD for these AC motors.

Lastly, the instrumentation that is on the hydraulic power packs is traditionally deployed either for operator display of pressure and flow or for an emergency shut-off of the unit. This is done in case the unit builds up high pressure due to a line clog, rather than using this instrumentation for a close-loop control of the AC motors.

By connecting the existing instrumentation directly into the digital inputs of the VFD, adding additional analog transducers to the hydraulic system and integrating all to the VFD, it will generate more efficient control of the power pack, at a lower cost and minimum maintenance.

In recent years, VFDs have been IoT-enabled. With the instrumentation going directly into the VFD, the user acquires the benefit of predictive maintenance to reduce unwanted downtime.

What would a smart hydraulic power pack design look like?

- Install a VFD for a hydraulic pump motor and another one for a cooling pump motor on the heat exchanger. On mission-critical hydraulic power packs there are redundant motors for each. In that instance you would need to install separate VFDs for redundant motors.

- Close all valves in the bypass line. The emergency relief valve should be set so that it only comes into the picture when the drive fails to regulate the pressure.

- Install a differential pressure sensor between the supply and return headers at the process load (located the furthest distance from the power pack). Determine the pressure drop needed to maintain enough flow through the farthest process load point in the hydraulic network. Control the speed of the hydraulic pump VFD using internal PID to maintain enough differential pressure.

- Install a temperature transducer at the hydraulic power pack to feed back the oil temperature to the heater exchanger VFD and control the cooling water flow through the heat exchanger.

- Enable the IoT on the VFDs to send the smart information to a smartphone periodically, comparing information in order to alert a user to take proactive maintenance measures when necessary.

Tying it all together: How would a smart hydraulic power pack work efficiently with predictable downtime?

The induction motor on the hydraulic pump should be controlled by a VFD rather than across the line starter. VFD speed reference can be controlled by the drive internal PID controller that receives feedback from a differential pressure transducer added to the hydraulic system. The set point for the PID will be to maintain enough dP pressure at the furthest point in the hydraulic network.

What this means is that following the affinity rules, VFD will run a hydraulic pump motor at a speed required to maintain the pressure setpoint rather than always running at full speed when running across the line starter, consuming power while idling.

Applying the first principle, a hydraulic pump and electric motor combination on a hydraulic power will control the oil flow to actuate a piston or rotate a hydraulic motor. The flow (gpm) is a function of oil displacement per revolution * rotational speed. Therefore, a VFD can be used to reduce the speed of the pump to control the flow when the minimum flow is required during the times the hydraulic system is idle.

During the work executed by hydraulic system, certain flow is maintained which is related to dP at the farthest point, accounting for work being done by the actuator or any leakage. This constant flow gives rise to pressure difference due to resistance offered by the load.

Therefore, using the VFD PID in a closed loop controls the motor speeds; over-pressurization of the system does not occur during the idle times, and the flow required to maintain the required pressure is delivered during the time of work being done by the hydraulic system.

Overall, it can be seen that by reducing the speed of the pump when the system is idle and running the pump just at the required speed to maintain enough flow during the non-idle phase can save energy and running costs on a system that is in operation 24/7 in any given application. If the speed is not reduced and the oil is still being pumped without doing any work, it will take the path of least resistance and will return to the reservoir through the pressure relief valve, costing unnecessary energy usage for the user.

Secondly, on a system where it is well defined dP that is to be maintained, the system already knows the normal operating speed of the motor. Therefore, an event of leakage in the system will cause the pump to run at a speed higher than normal over time. This indicates that the pump needs tuning or that there is a leakage in the system. This is the predictive diagnostics advantage of using a VFD for the hydraulic pump.

Also, by wiring the existing flow switch and the pressure switch to the digital inputs on the drive, the drive will shut off automatically if programed to trip when either one of these switches trigger. By providing additional smart safety and an IoT-enabled drive, it gives users a timely notification of an action required by the maintenance team.

The viscosity of the oil is an important function for preventing any cavitation of the pump and attaining the required flow at the design pressure. Maintaining oil temperature is key to maintaining the oil viscosity. Depending on the size of the hydraulic system the units have some sort of heat exchanger unit for maintaining the oil temperature. If the heat exchanger motor is controlled with the VFD, using a PID controller for regulating the cooling water flow based on the temperature of the oil will save energy costs, as the power is P (Power) α Ƭ (Motor Torque) * N (Speed).

Because the components of the hydraulic power pack were designed and commissioned with operating parameters such as motor current, motor speed and pressure, any change in these parameters over time is a good indication to the user as part of the predictive maintenance feature. It alerts user that something has changed in the system, such as leakage, bearing loss or clogged lines (hence the motor is running at a higher speed than normal to achieve the required pressure). With the IoT-enabled VFDs, all these parameters are available to users at their fingertips to enhance ease of use and the data management experience.

In summary, the use of the VFDs and some additional instrumentation on hydraulic power packs can provide the user with energy savings, reduced downtime and reduced maintenance cost due to predictive maintenance.

Ranbir (Ron) Ghotra is a product line application engineer at Eaton. Ghotra has 20 years of global experience in engineering and managing control and automation projects, solving problems for various industries ranging from residential to aerospace. He is a project management professional with a Bachelor’s degree in electrical engineering and an MBA from Katz Business School.